Preparation method of ultra-fine desulfurizer slurry and device thereof

A technology for preparing devices and desulfurizers, which is applied in the field of flue gas desulfurization, can solve the problems of low desulfurization efficiency of the desulfurizer calcium utilization rate system, reduce the injection amount of desulfurizer slurry, and low reactivity of desulfurizers, so as to avoid lime activity. Reduce and solve the problem of wall sticking and fouling, and realize the effect of efficient and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

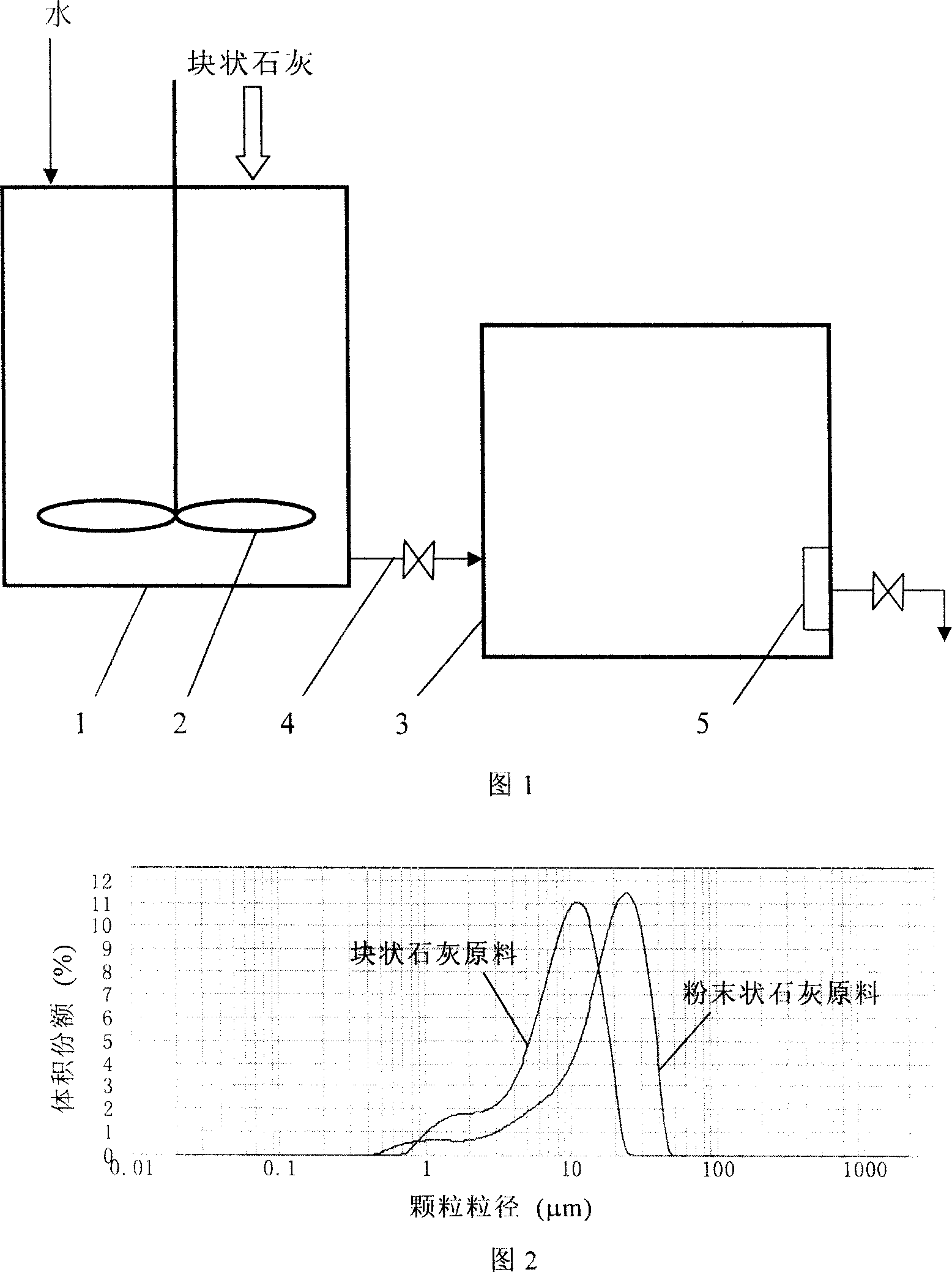

[0033]The following introduces the comparison experiment of desulfurizer slurry preparation using block lime and powder lime produced by Shougang Building Materials Chemical Plant as raw materials. Pour 50 kg each of block lime with a particle size of 10 to 30 mm and powdered lime with a particle size of 0.2 to 700 μm into the hydration reactor, and the CaO content in the lime is 86.5%; then, add 210 liters of water for digestion, the molar ratio of water for digestion to CaO in the lime is 15; then, the hydration reactor is placed in a static state for 15 minutes, so that the lime and water can fully carry out the hydration reaction process; then, add 75 liters of pulping water is prepared into a desulfurizer slurry with a mass concentration of 15%; at last, start the agitator 2 in the hydration reactor 1 to obtain a uniformly suspended desulfurizer slurry, and pass the desulfurizer slurry through the hydration reactor 1 and The connecting pipeline 4 between the slurry storag...

Embodiment 2

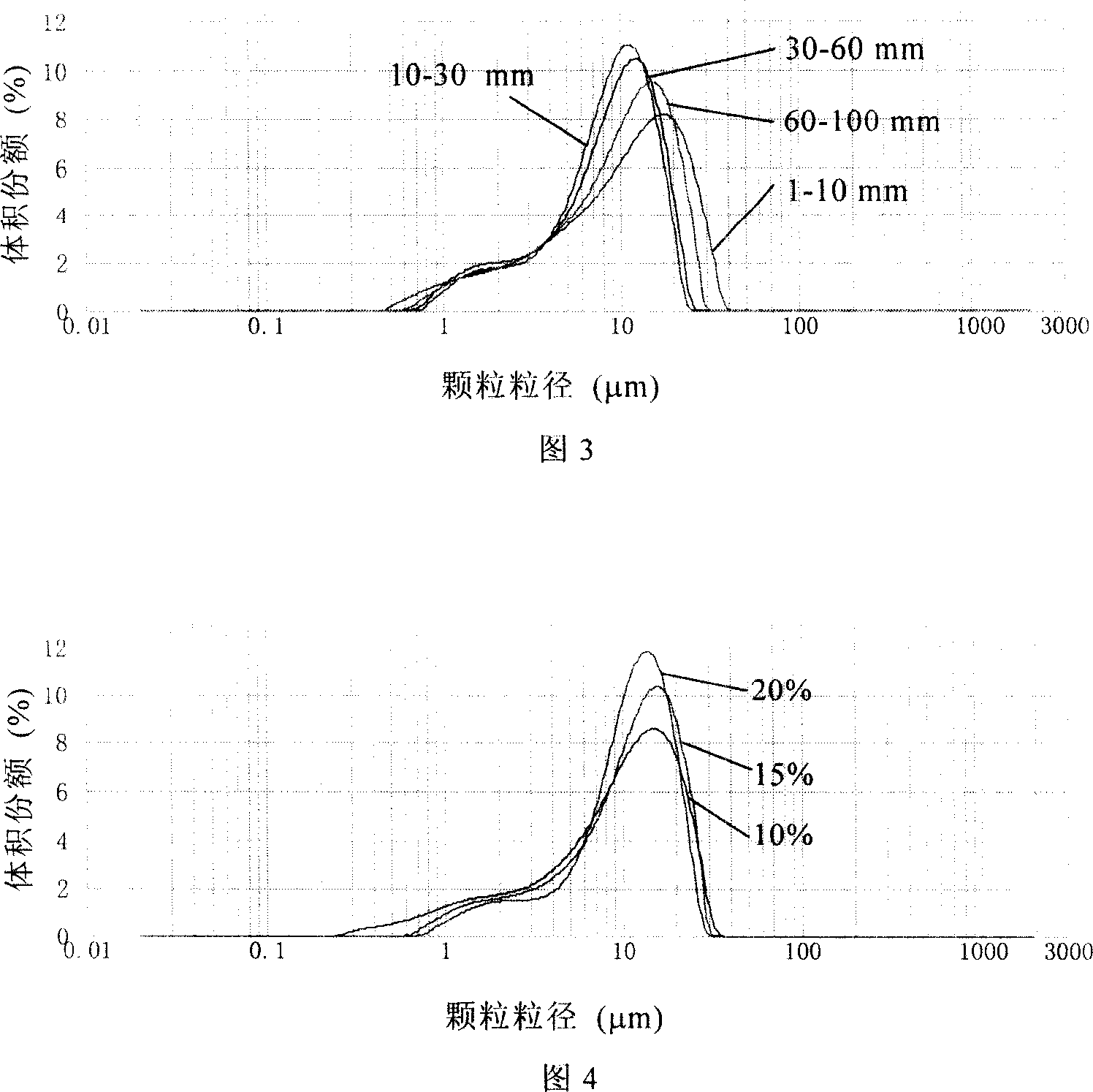

[0038] Pour 50 kg each of four block lime samples with particle diameters ranging from 1 to 10 mm, 10 to 30 mm, 30 to 60 mm and 60 to 100 mm into the hydration reactor, and the CaO content in the lime is 86.5%; Add 210 liters of water for digestion into the reactor, the molar ratio of the water for digestion to CaO in the lime is 15; then, the hydration reactor is placed in a standing state for 15 minutes, so that the lime and water can fully carry out the hydration reaction process; Add 75 liters of pulping water into the reactor to prepare desulfurizer slurry with a mass concentration of 15%. Other preparation conditions are with embodiment 1. Table 2 shows the particle size comparison results of calcium hydroxide particles in the desulfurizer slurry prepared by using four lump lime pairs with different particle size ranges. Figure 3 shows the effect of particle size distribution of calcium hydroxide particles in the desulfurizer slurry prepared by using lump limes with fou...

Embodiment 3

[0042] Pour 30 kilograms of block lime with a particle size range of 10 to 30 mm into the hydration reactor, and the CaO content in the lime is 86.5%; then, add 167 liters, 126 liters and 83 liters of digestion water to the hydration reactor respectively, The molar ratios of the digestion water to the CaO in the lime are 20, 15 and 10 respectively; then, the hydration reactor is placed in a static state for 30 minutes, so that the lime and water can fully carry out the hydration reaction process; then, add 103 liters, 45 liters and 37 liters of pulping water were used to prepare desulfurizer slurries with mass concentrations of 10%, 15% and 20%, respectively. Other preparation conditions are with embodiment 1. Table 3 shows the particle size comparison results of calcium hydroxide particles in the above three desulfurizer slurries with different mass concentrations. Figure 4 shows the effect of the particle size distribution of calcium hydroxide particles in the desulfurizer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com