Crushing device, breaking method and application of pile head of cast-in-place bored pile

A technology of bored piles and crushing devices, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc. It can solve the problems of large impact on the quality of pile head reinforcement, low efficiency of pile head removal, and large impact on personnel health, etc., to achieve convenience Turnover and reuse, wide application range, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

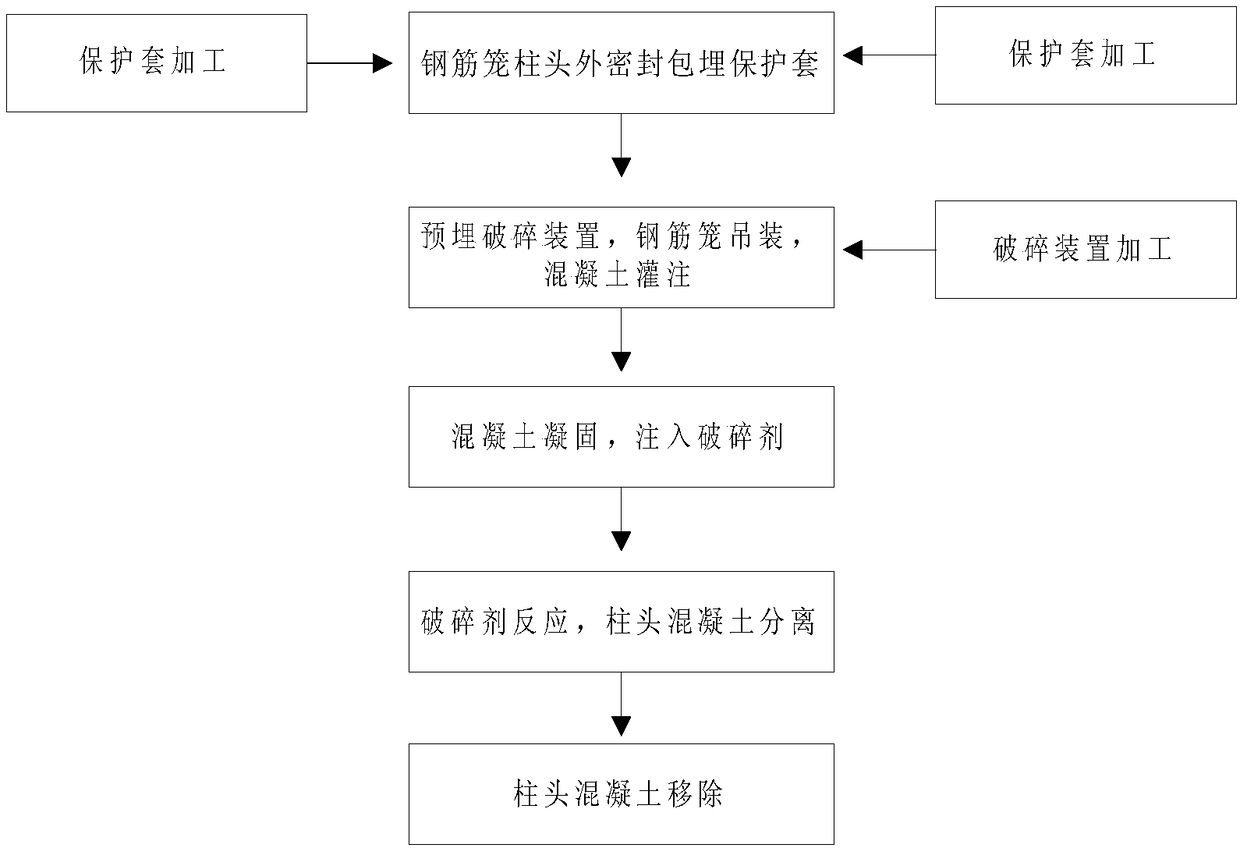

[0046] (1) Seal the exposed main bars of the steel cage, the acoustic measuring tube and the detecting tube to cover the PVC pipe respectively, and seal both ends of the PVC pipe to prevent concrete from entering the PVC pipe during the concrete pouring process;

[0047] (2) Pre-embed a crushing device at the top 10cm of the pile top elevation to separate the pile head concrete from the pile body concrete through horizontal expansion force. After installing the crushing device, hoist the reinforcement cage into the hole and fill it with concrete;

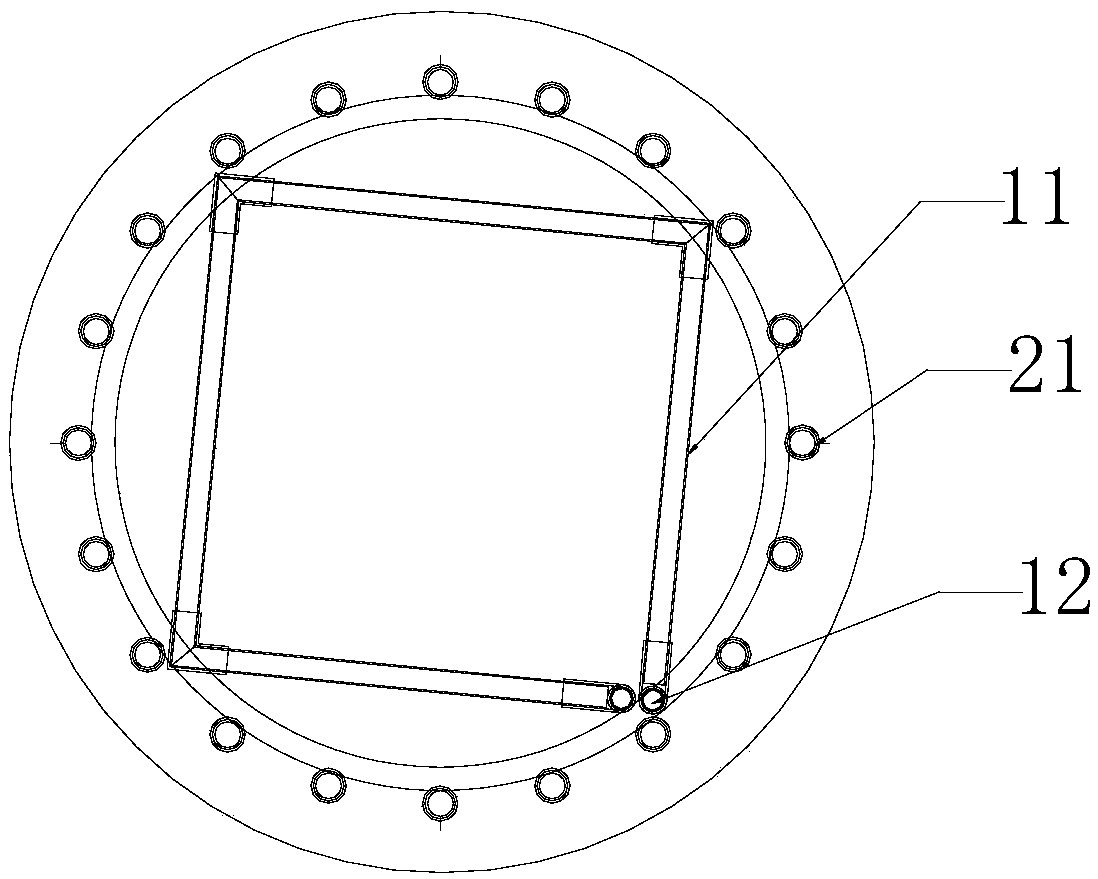

[0048] The horizontal crushing component 11 of the crushing device adopts a horizontal ring-shaped hollow Φ40 PVC pipe, and the injection pipeline 121 and the observation pipeline 122 adopt Φ40 PVC pipes, which are connected through adapter joints and extend to more than 20 cm above the ground; the horizontal crushing component 11 is reinforced and fixed by steel bars, and injected The pipeline 121 and the observation pipeline 122 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com