Magnetic liquid sealing device

A magnetic liquid and sealing device technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of magnetic liquid seals not working properly, equipment not running normally, etc., to prevent axial displacement, reduce starting torque, The effect of reducing the injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

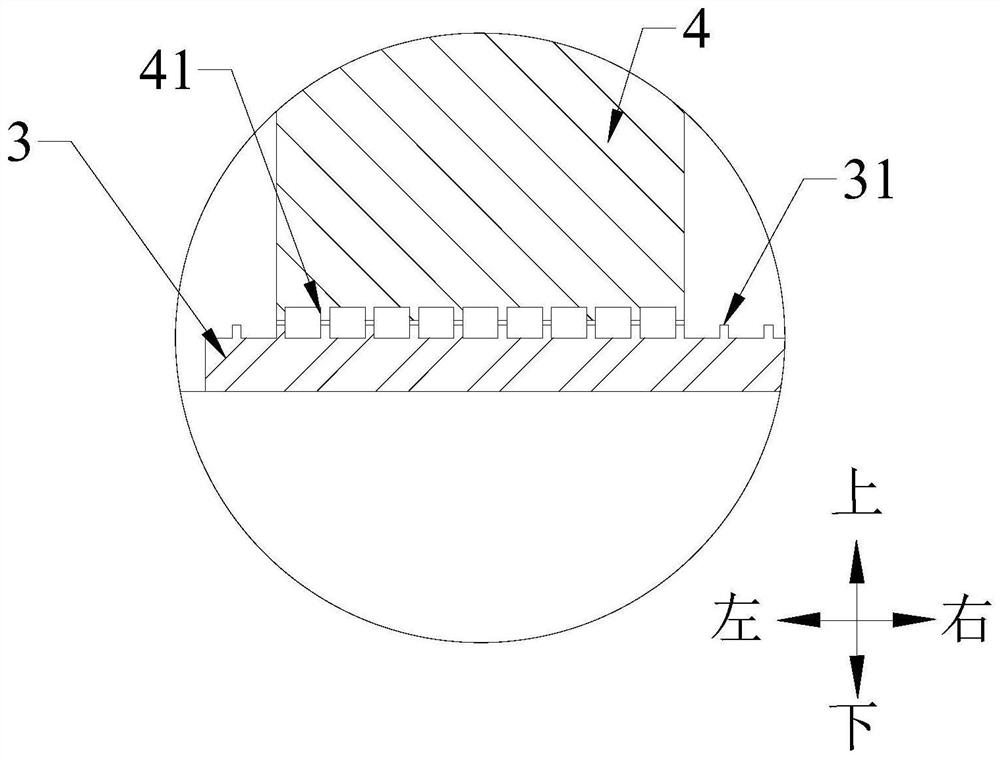

[0026] Such as figure 1 and figure 2 As shown, the magnetic liquid sealing device according to the embodiment of the present invention includes a housing 1 , a rotating shaft 2 , a shaft sleeve 3 , a first pole piece 4 , a second pole piece 5 , a permanent magnet 6 and an end cover 7 .

[0027] The housing 1 has a chamber inside. Such as figure 1 As shown, the left end of the housing 1 is provided with a flange part 101, and the flange part 101 is provided with a plurality of threaded holes, and the flange part 101 is suitable for connecting with external equipment.

[0028] The rotating shaft 2 is rotatably arranged in the chamber. Such as figure 1 As sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com