Preparation method of composite drug-eluting stent and its drug coated layer

A technology of eluting stents and drug coating, applied in the field of medical drug eluting stents, can solve controversial problems and achieve the effect of reducing economic burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

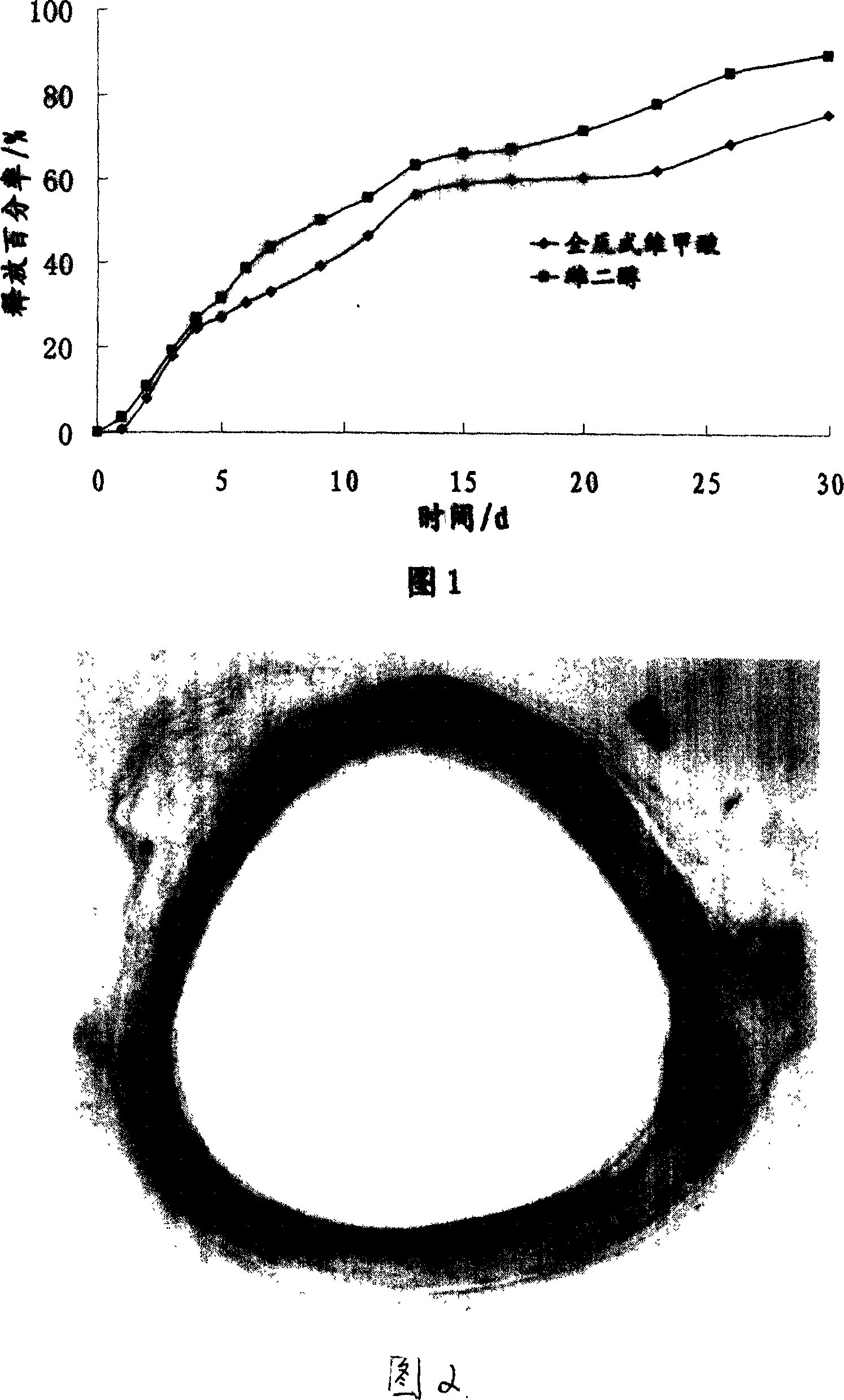

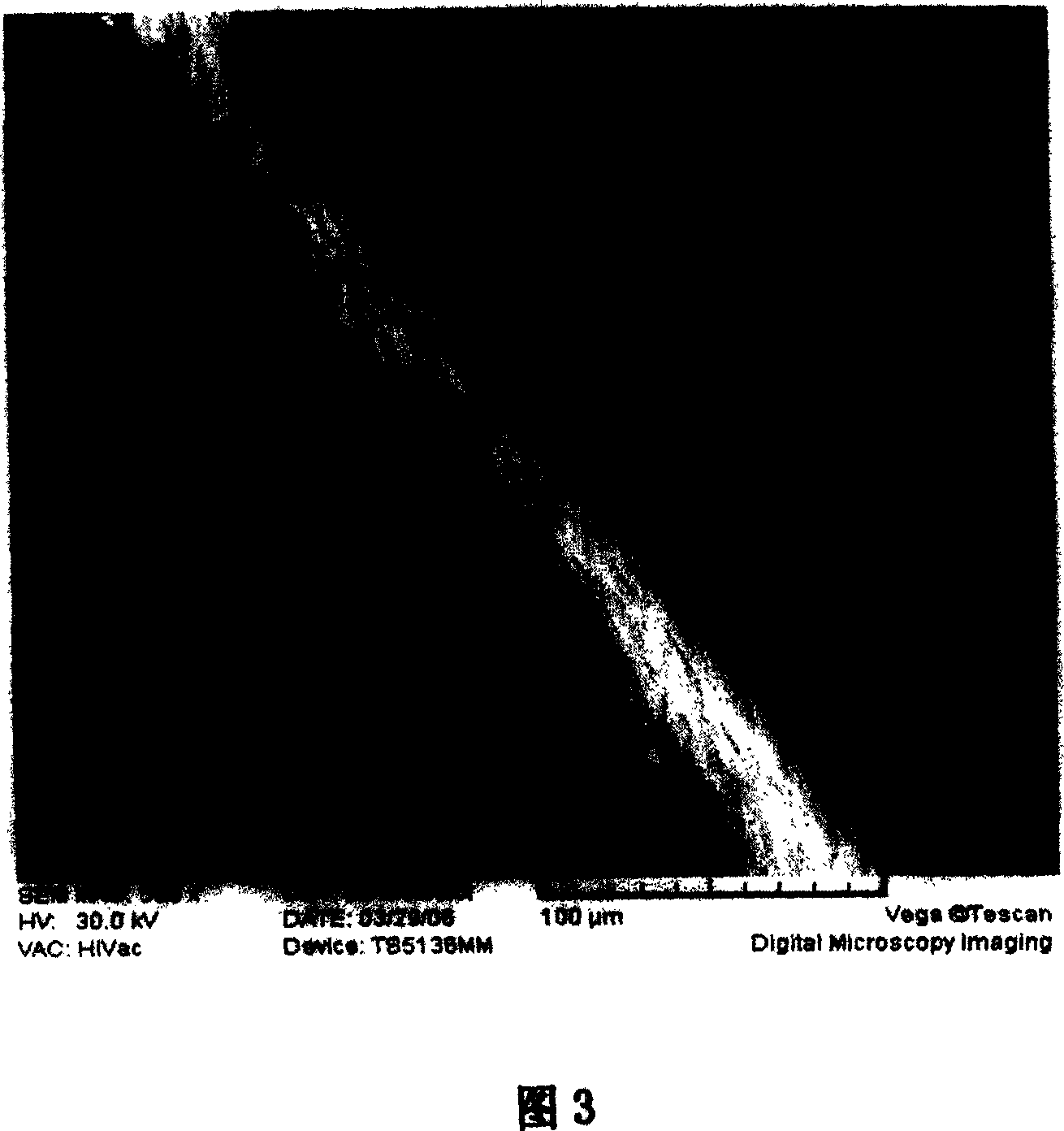

Embodiment 1

[0029]Weigh an appropriate amount of all-trans retinoic acid and PLA respectively according to a weight ratio of 1:4, dissolve them in tetrahydrofuran and set the volume to a solid content of 1%. The retinoic acid coating solution is sprayed onto the surface of the pretreated bare metal stent by using an atomizing spraying device, and then cured and dried in a vacuum at room temperature to obtain a retinoic acid layer coating. Appropriate amounts of estradiol and PLA were weighed at a weight ratio of 1:4, dissolved in tetrahydrofuran to a solid content of 1%. The estradiol coating solution is sprayed onto the outside of the retinoic acid coating of the stent by using an atomizing spraying device, and then cured and dried in a vacuum at room temperature to obtain an all-trans retinoic acid estradiol composite eluting stent 1 .

Embodiment 2

[0031] Weigh an appropriate amount of all-trans retinoic acid and polyacrylic acid resin silica nanocomposite material respectively according to the weight ratio of 4:6, dissolve them in tetrahydrofuran and set the volume to a solid content of 1%. The retinoic acid coating solution is sprayed onto the surface of the pretreated bare metal stent by using an atomizing spraying device, and then cured and dried in a vacuum at room temperature to obtain a retinoic acid layer coating. Weigh an appropriate amount of estradiol and polyacrylic acid resin silicon dioxide nanocomposite material respectively according to a weight ratio of 3:7, dissolve them in tetrahydrofuran and set the volume to a solid content of 1%. The estradiol coating solution is sprayed onto the outside of the retinoic acid coating of the stent by using an atomizing spraying device, and then cured and dried in a vacuum at room temperature to obtain an all-trans retinoic acid estradiol composite eluting stent 2 .

Embodiment 3

[0033] Weigh appropriate amount of all-trans retinoic acid, estradiol and polyacrylic resin silicon dioxide nanocomposite material respectively according to the weight ratio of 1:1:3, dissolve with tetrahydrofuran and set the volume to 1% solid content. Spray the mixed drug coating solution on the surface of the pretreated bare metal stent by using an atomizing spraying device, and then cure and dry in a vacuum at room temperature to obtain a mixed drug coating. Weigh an appropriate amount of polyacrylic resin silica nanocomposite material, and use tetrahydrofuran ultrasonic Dissolving to obtain a 0.5% coating solution by weight. Using the aforementioned coating method, the polyacrylic acid resin silica nano-coating solution is applied to the surface of the drug stent coated with the all-trans retinoic acid estradiol layer coating to obtain the all-trans retinoic acid estradiol composite eluting stent 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com