Rolled heat exchanger

A heat exchanger and winding technology, applied in the field of winding heat exchangers, can solve problems such as expensive, high inertia, and troublesome manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

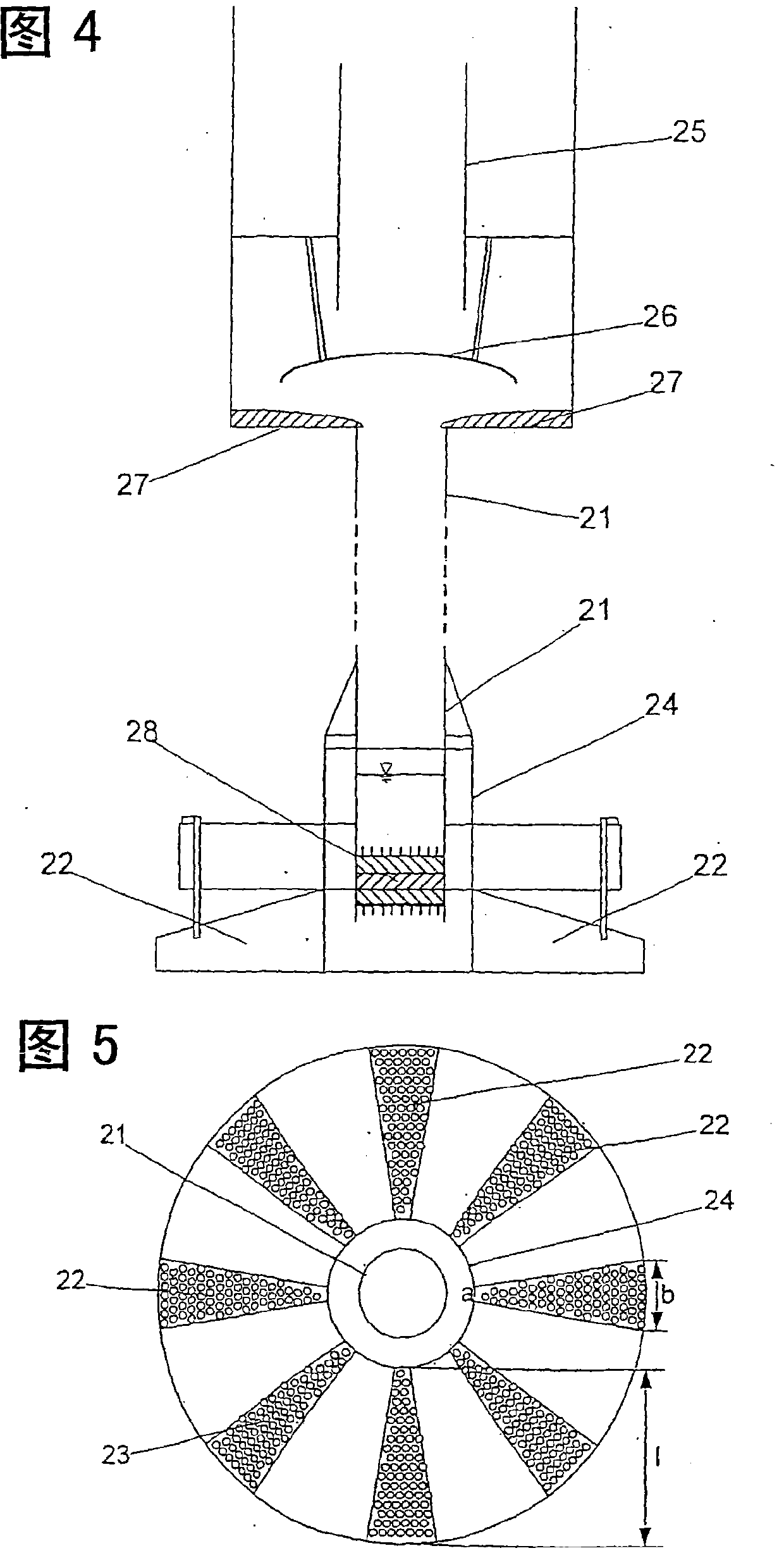

[0026] figure 1 shows a top view of a conventional liquid distributor for a wound heat exchanger used, for example, as a liquefier in an LNG base-type production plant. The liquid distributor has three pie-segment-shaped perforated bottom plates 1 which are arranged uniformly around the core tube 2 of the heat exchanger and extend as far as the cylindrical shell 3 of the heat exchanger. A plurality of tubes are wound on the core tube 2 and are guided through the distributor in the open regions 4 between the individual perforated base plates 1 .

[0027] The perforated bottom plate 1 is provided with a plurality of drip openings 5 through which the liquid on the perforated bottom plate 1 can drip onto the tube bundle located below.

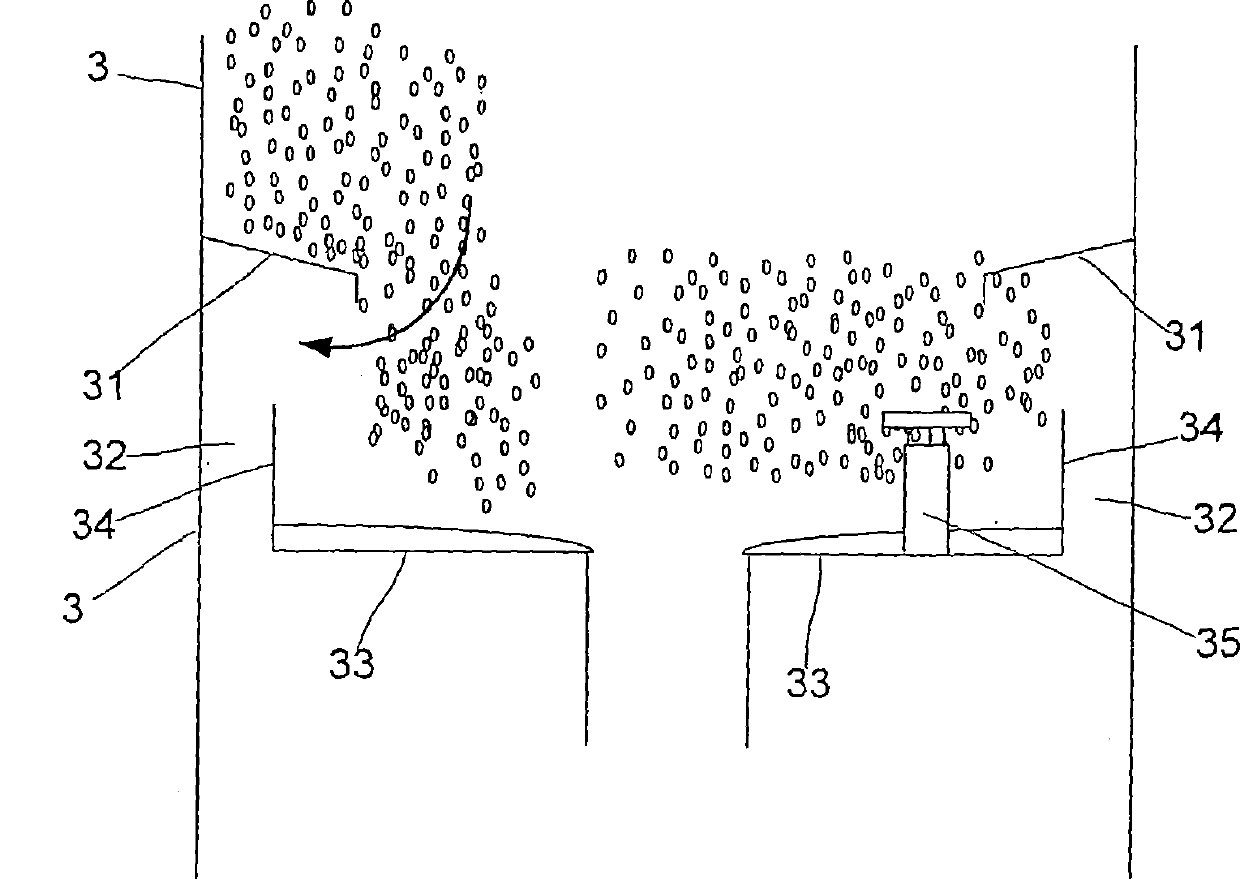

[0028] The supply of liquid takes place via a ring pre-distributor as in the figure 2 and image 3 as shown schematically. The annular predistributor has a lateral liquid inlet 6 which opens into a surge tank 7 . The side 8 of the buffer bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com