Assembled piston for an internal combustion engine

A combined internal combustion engine technology, applied to pistons, mechanical equipment, engine components, etc., can solve problems such as low thread connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

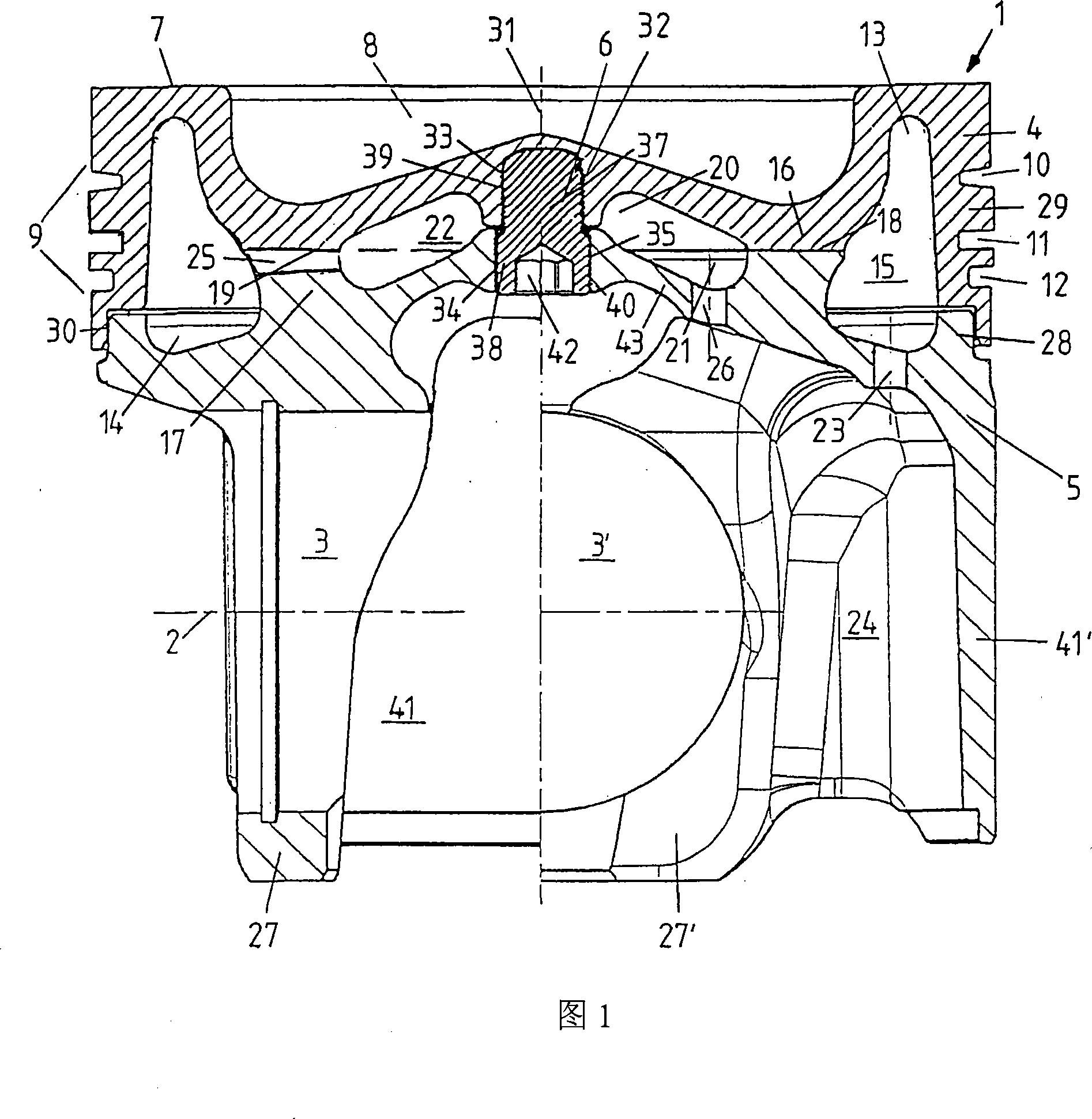

[0046] A combined piston 1 is shown in a cross-sectional view, the left half of the cross-sectional view shows a cross-section of the piston 1 along the longitudinal axis 2 of the piston pin seat hole 3, and the right half shows Piston 1 sectional view staggered 90° with the left half. The piston 1 consists of an upper part 4 and a lower part 5, which are connected to each other by means of a hexagon socket head screw 6 arranged in the middle, so that the hexagon socket 42 of the hexagon socket screw 6 is located inside the piston.

[0047] The upper part 4 and the lower part 5 of the piston 1 are preferably manufactured from forged steel. It is also conceivable to manufacture the upper part 4 from steel and the lower part 5 from aluminum, as well as the upper part 4 from forged steel and the lower part 5 from cast aluminum.

[0048] The cylindrical upper part 4 forms a piston crown 7 in which a rotationally symmetrical combustion chamber 8 is formed. The radially outer surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com