Technique for extracting vanadium pentoxide by the pulp resin method

A technology of vanadium pentoxide and resin, which is applied in the field of extraction of vanadium pentoxide by pulp resin method, can solve the problems of slow adsorption of vanadium ions, inability to completely separate coarse-grained ore from precious liquid, and low saturation of resin adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

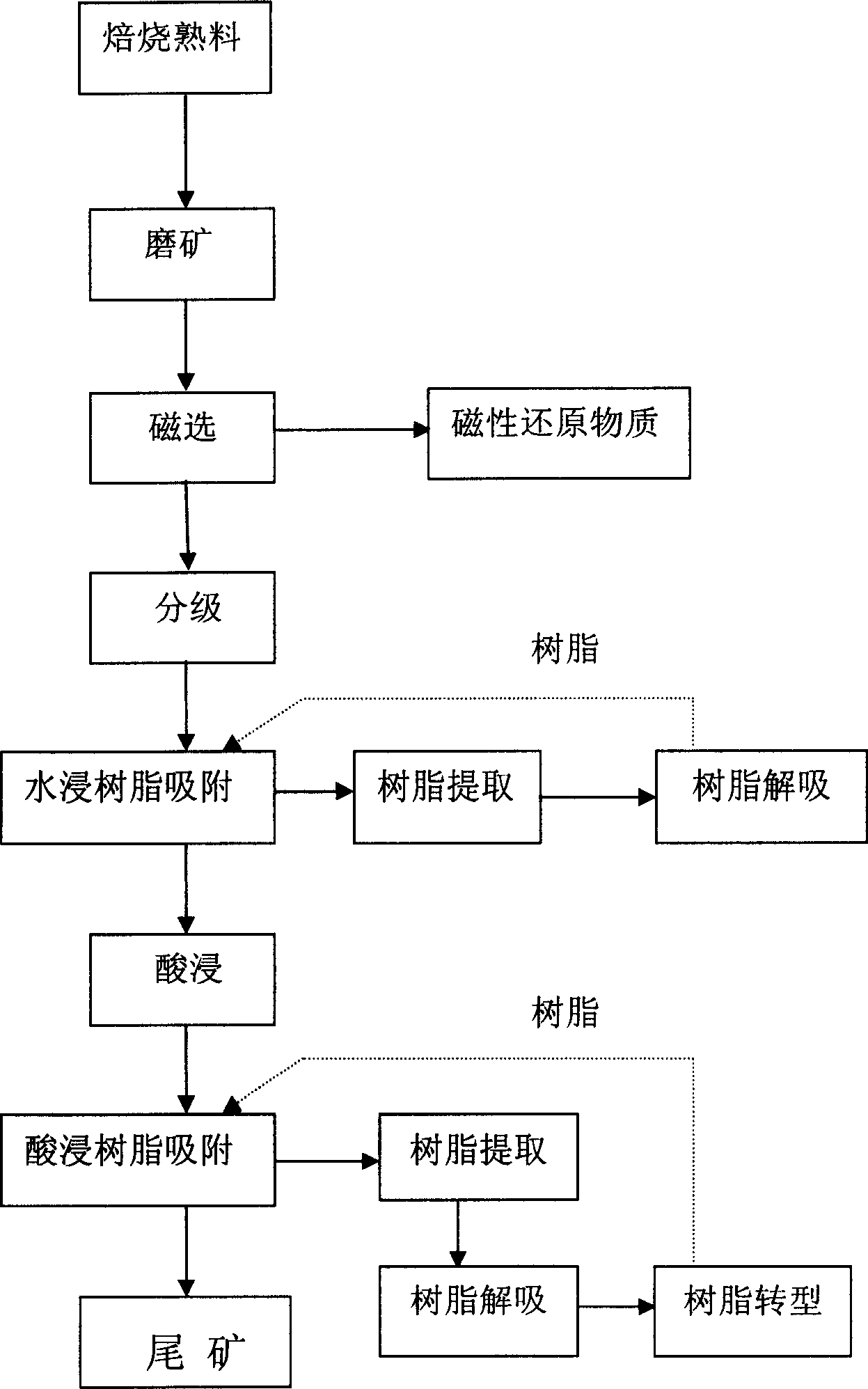

Image

Examples

Embodiment 1

[0009] Embodiment 1: A kind of pulp resin method extracts vanadium pentoxide process, first the stone coal vanadium ore roasting clinker is wet-grinded to a fineness of less than 0.1mm with a ball mill, and then the ore powder is magnetically separated with a magnetic separator, The iron filings and magnetic reducing substances in the ore powder are selected to reduce the amount of oxidant in the subsequent operation, and the underflow of the magnetic separation enters the water immersion resin adsorption operation. After wet-grinding the roasted clinker with a grinding machine, the particle size classification can be carried out with a spiral classifier or a hydrocyclone, so that the amount of ore powder with a fineness of less than 0.074mm in the ore powder obtained after wet grinding accounts for at least 70% of the total amount of ore powder is produced. Keep the pulp concentration at 25%, and the pulp enters the water immersion resin adsorption stirring tank, and adds D20...

Embodiment 2

[0010] Embodiment 2: A kind of pulp resin method extracts vanadium pentoxide process, first the stone coal vanadium ore roasting clinker is wet-grinded to a fineness of less than 0.1mm with a ball mill, and then the ore powder is magnetically separated with a magnetic separator, The iron filings and magnetic reducing substances in the ore powder are selected to reduce the amount of oxidant in the subsequent operation, and the underflow of the magnetic separation enters the water immersion resin adsorption operation. After the roasted clinker is wet-grinded with a grinding machine, a spiral classifier can be used for particle size classification, so that the amount of ore powder with a fineness of less than 0.06mm in the ore powder obtained after wet grinding accounts for at least the total amount of the ore powder. 80% of. Keep the pulp concentration at 35%, and the pulp enters the water immersion resin adsorption stirring tank, and adds 307 weakly basic anion [Cl - ] type re...

Embodiment 3

[0011] Embodiment 3: A kind of pulp resin method extracts vanadium pentoxide process, first the stone coal vanadium ore roasting clinker is wet-grinded to a fineness of less than 0.1mm with a ball mill, and then the ore powder is magnetically separated with a magnetic separator, The iron filings and magnetic reducing substances in the ore powder are selected to reduce the amount of oxidant in the subsequent operation, and the underflow of the magnetic separation enters the water immersion resin adsorption operation. After wet-grinding the roasted clinker with a grinding machine, a hydrocyclone can be used for particle size classification, so that the amount of ore powder with a fineness less than 0.074mm in the ore powder obtained after wet grinding accounts for at least 90% of the amount. Keep the pulp concentration at 40%, and the pulp enters the water immersion resin adsorption stirring tank, and adds D201 weakly basic anion [Cl -] type resin is used for water leaching and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com