Composite board of small pieces of bamboo reinforcement, and manufacturing method

A composite sheet and manufacturing method technology, applied in the field of sheet manufacturing, can solve the problems of low mechanical strength of products, failure to meet performance requirements, and large consumption of raw materials, etc., achieve good physical and mechanical properties and appearance quality, improve comprehensive utilization, and structure well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

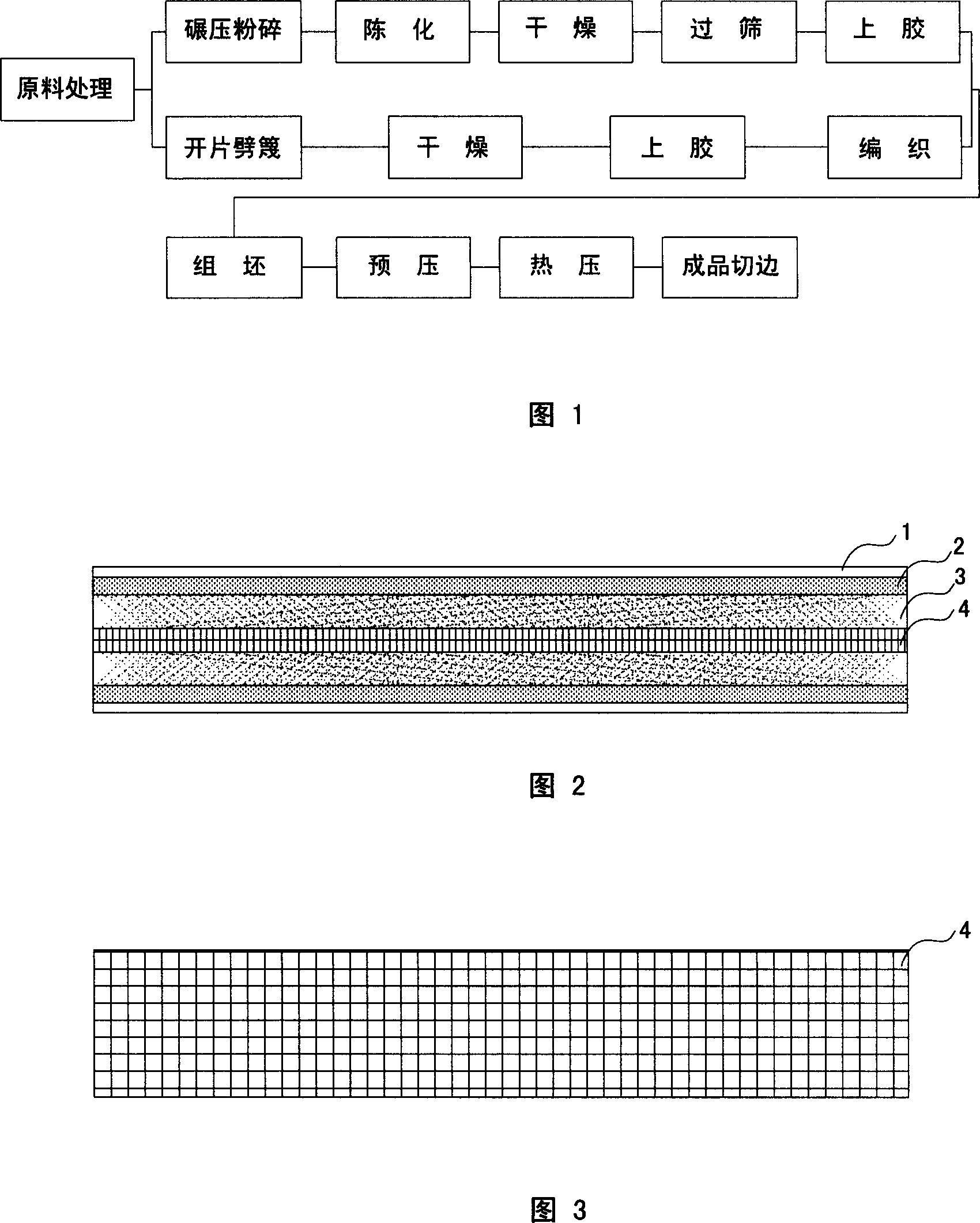

[0041] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0042] As shown in Figure 1, Figure 2, and Figure 3,

[0043] 1) Prepare raw materials: bamboo, the bamboo used to make the bamboo reinforcement net can be moso bamboo, or other bamboo species can be used. Moso bamboo is generally 5-year-old (3 degrees) more suitable, and other bamboo species are 3-year-old more suitable; choose one or more of bamboo branches, bamboo wood processing residues or plant straws.

[0044]2) The bamboo branches or bamboo and wood processing residues or plant straws are mechanically crushed and pulverized.

[0045] 3) stacking and aging, and drying to a moisture content of 6-15%.

[0046] 4) Sieve the dried scraps and stack them according to the coarseness and subdivision. Taking a board with a size of 122×244×1.2cm as an example, use 28kg of scraps with a density of 0.8-1.2g / cm 3 .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com