Electroconductive rubber composition

A silicone rubber composition and conductivity technology, applied in the direction of carbon-silicon compound conductors, etc., can solve the problems of fluctuation in physical properties, difficult to mix rubber, damage to the cold resistance and physical properties of silicone rubber, and achieve less sheet adhesion and electrical conductivity. Excellent performance and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

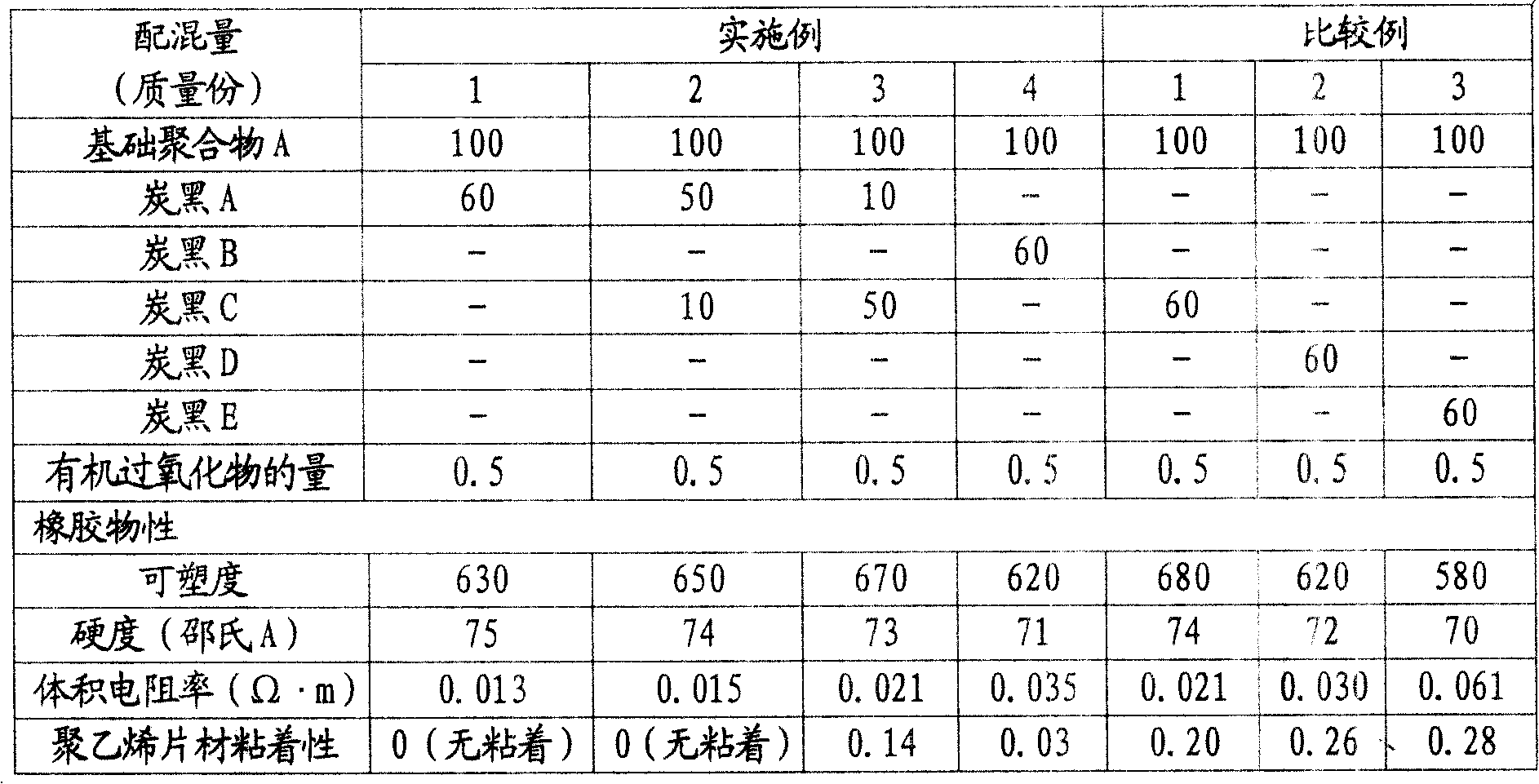

Embodiment 1

[0066] Containing 99.825 mol% of dimethyl siloxane units and 0.15 mol% of methyl vinyl siloxane units, both ends of the molecular chain are capped with 0.025 mol% of dimethyl vinyl silyl groups, and the average degree of polymerization is 8000 In 100 parts of organopolysiloxane, add BET specific surface area 65m 2 60 parts of carbon black A (manufactured by TIMCAL (KK), trade name "ENSACO 250G"), DBP oil absorption 190ml / 100g, degree of graphitization d(002) of 0.347nm was placed in a kneader as carbon black, and carried out After kneading, 0.5 part of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane as a cross-linking agent was charged and uniformly mixed to obtain a silicone rubber composition.

Embodiment 2

[0068] In addition to adding 50 parts of carbon black A (manufactured by TIMCAL Co., Ltd., trade name "ENSACO 250G") and BET specific surface area of 69m 2 / g, DBP oil absorption 125ml / 100g, graphitization degree d (002) is 0.342nm acetylene carbon black C (Denki Kagaku Kogyo Co., Ltd. product, trade name denka black granular product) 10 parts as carbon black, add and mix Except that, a silicone rubber composition was obtained in the same manner as in Example 1.

Embodiment 3

[0070] Except that 10 parts of carbon black A (manufactured by TIMCAL Co., Ltd., trade name "ENSACO 250G") and 50 parts of acetylene carbon black C (manufactured by Denki Kagaku Kogyo Co., Ltd., trade name denka black granular product) were prepared at this ratio and used as Except for carbon black, a silicone rubber composition was obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com