Process of extracting algal brown pigment from brown alga and use thereof

A technology of phycoxanthin and brown algae, which is applied in the field of extraction and separation of phycoxanthin, and can solve problems such as complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) pulverizing brown algae dry raw materials;

[0026] 2) Put the pulverized brown algae dry raw material in 6 times the amount of 80% ethanol and extract 3 times at 60°C, stirring from time to time during the extraction process;

[0027] 3) The extract is filtered, then concentrated to no alcohol;

[0028] 4) Take the precipitate, and then fully dissolve the precipitate with 5 times the amount of 80% ethanol;

[0029] 5) filtering the dissolved precipitate, and passing the filtrate through D101 adsorption resin;

[0030] 6) eluting the adsorption resin with 90% ethanol, taking the eluent and concentrating it into an extract;

[0031] 7) Add auxiliary materials to the extract and spray dry to obtain the product.

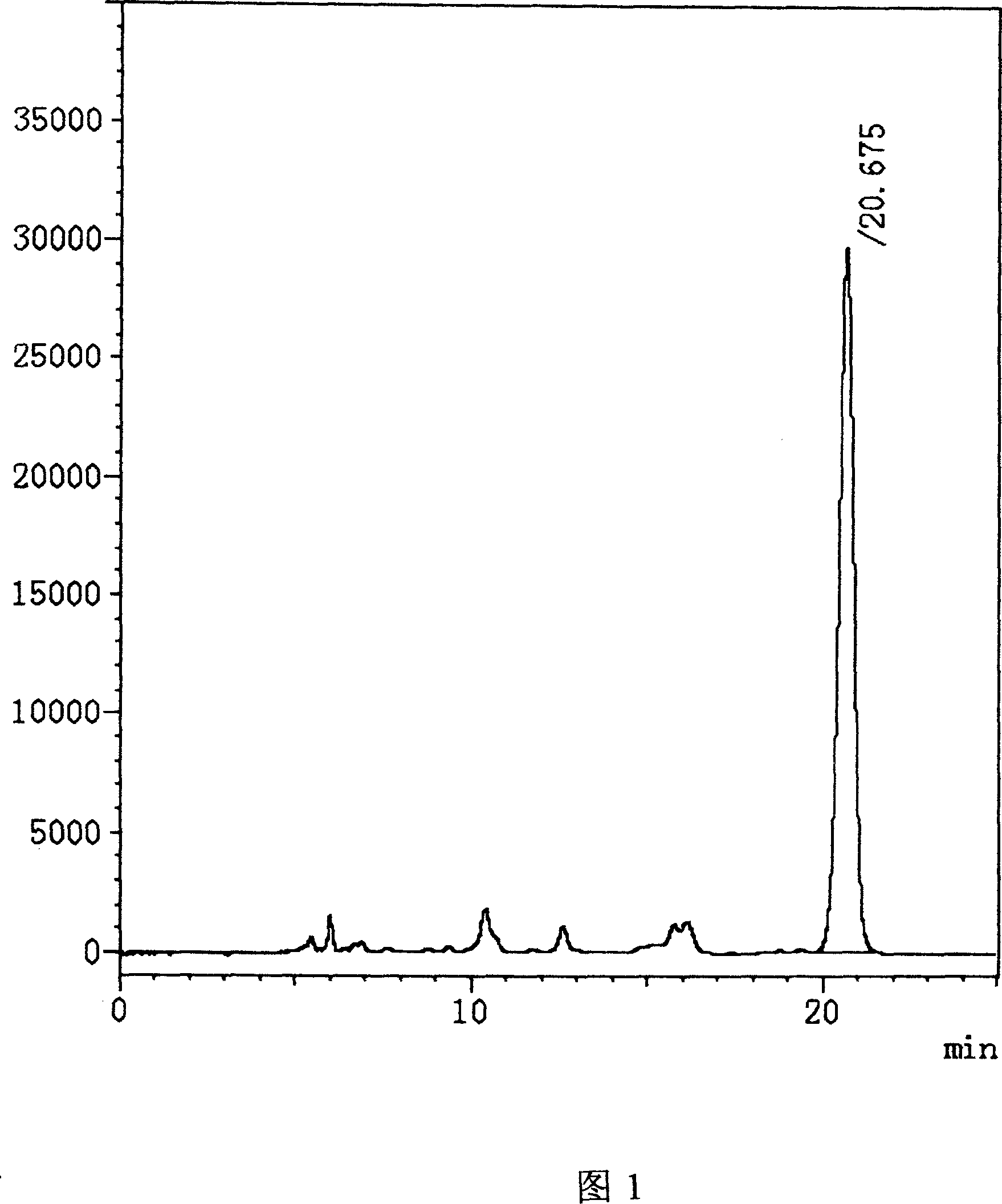

[0032] The HPLC collection of illustrative plates of the product prepared by the method of the present invention is shown in Figure 1, measured by HPLC method, the weight content of phycoxanthin in the product is 6.5%.

Embodiment 2

[0034] 1) pulverizing brown algae dry raw materials;

[0035] 2) Put the pulverized brown algae dry raw material in 6 times the amount of 95% ethanol and extract 3 times at 60°C, stirring from time to time during the extraction process;

[0036] 3) The extract is filtered, then concentrated to no alcohol;

[0037] 4) Take the precipitate, and then fully dissolve the precipitate with 5 times the amount of 80% ethanol;

[0038] 5) The precipitate after dissolving is filtered, and the filtrate is passed through HP-20 adsorption resin;

[0039] 6) eluting the adsorption resin with 90% ethanol, taking the eluent and concentrating it into an extract;

[0040] 7) Add auxiliary materials to the extract and spray dry to obtain the product.

[0041] As determined by the HPLC method, the weight content of phycoxanthin in the product is 18.8%.

Embodiment 3

[0043] A kind of antioxidant health food (hard capsule) formula:

[0044] Fucoxanthin (1%) 50g

[0045] Grape Seed Extract (95%) 350g

[0046] Vitamin C (98%) 250g

[0047] Soy Isoflavones (40%) 200g

[0048] Natural VE powder (VE50%) 200g

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com