Flexible rotary bearing

A slewing bearing and flexible technology, applied in the field of bearings, can solve the problems of increased friction and reduced slewing performance, and achieve the effects of smooth motion, low use cost and strong corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

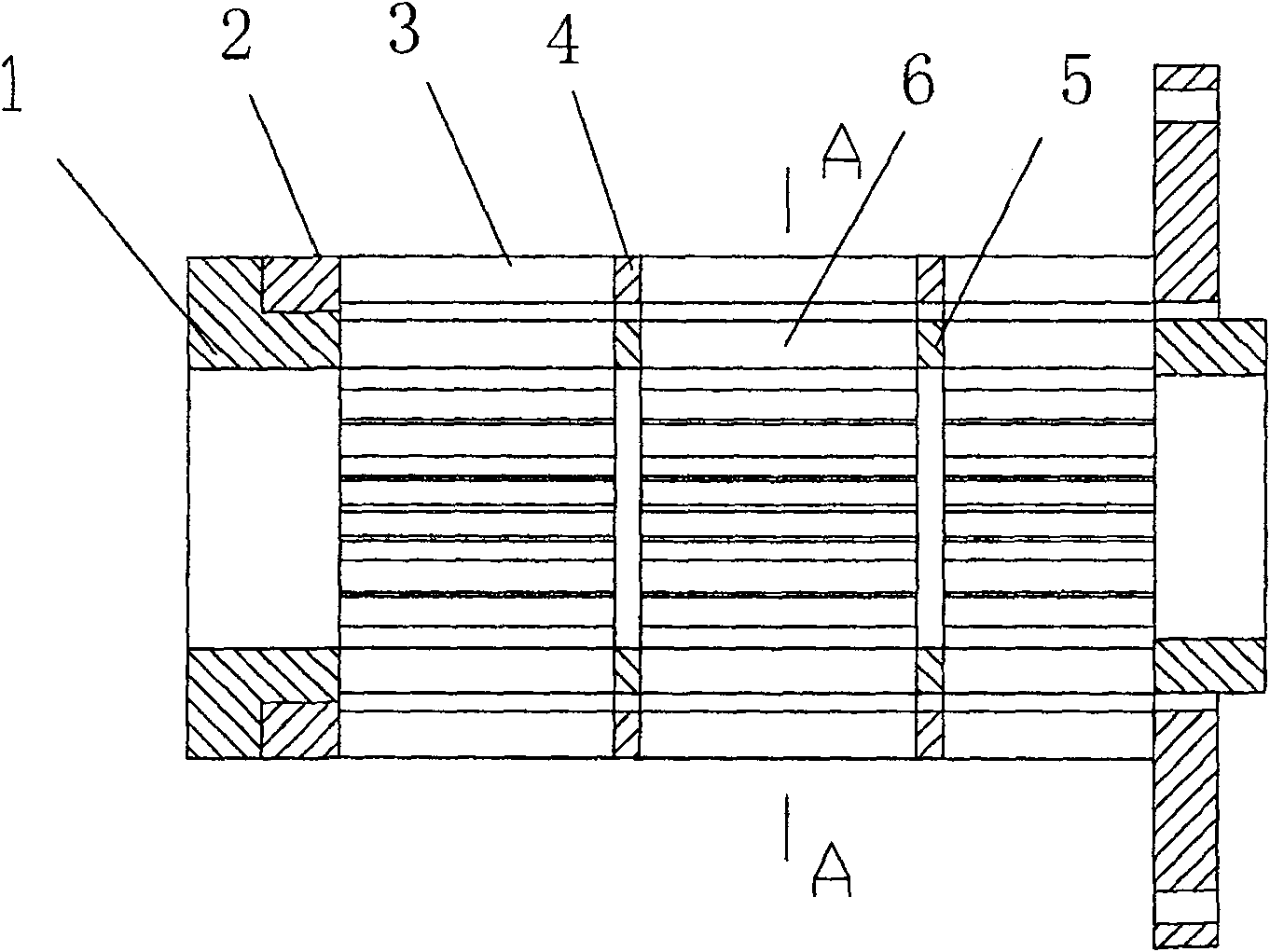

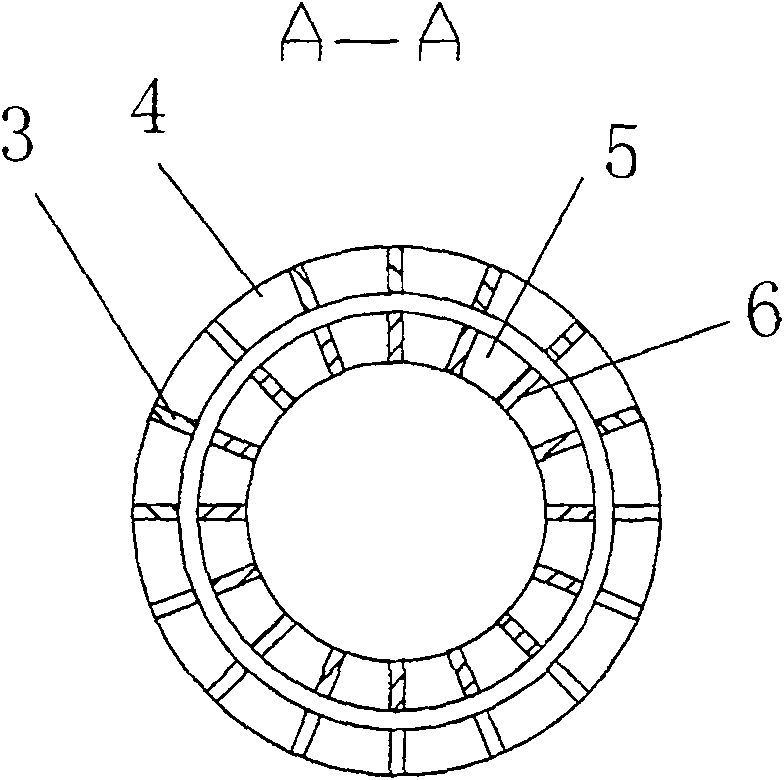

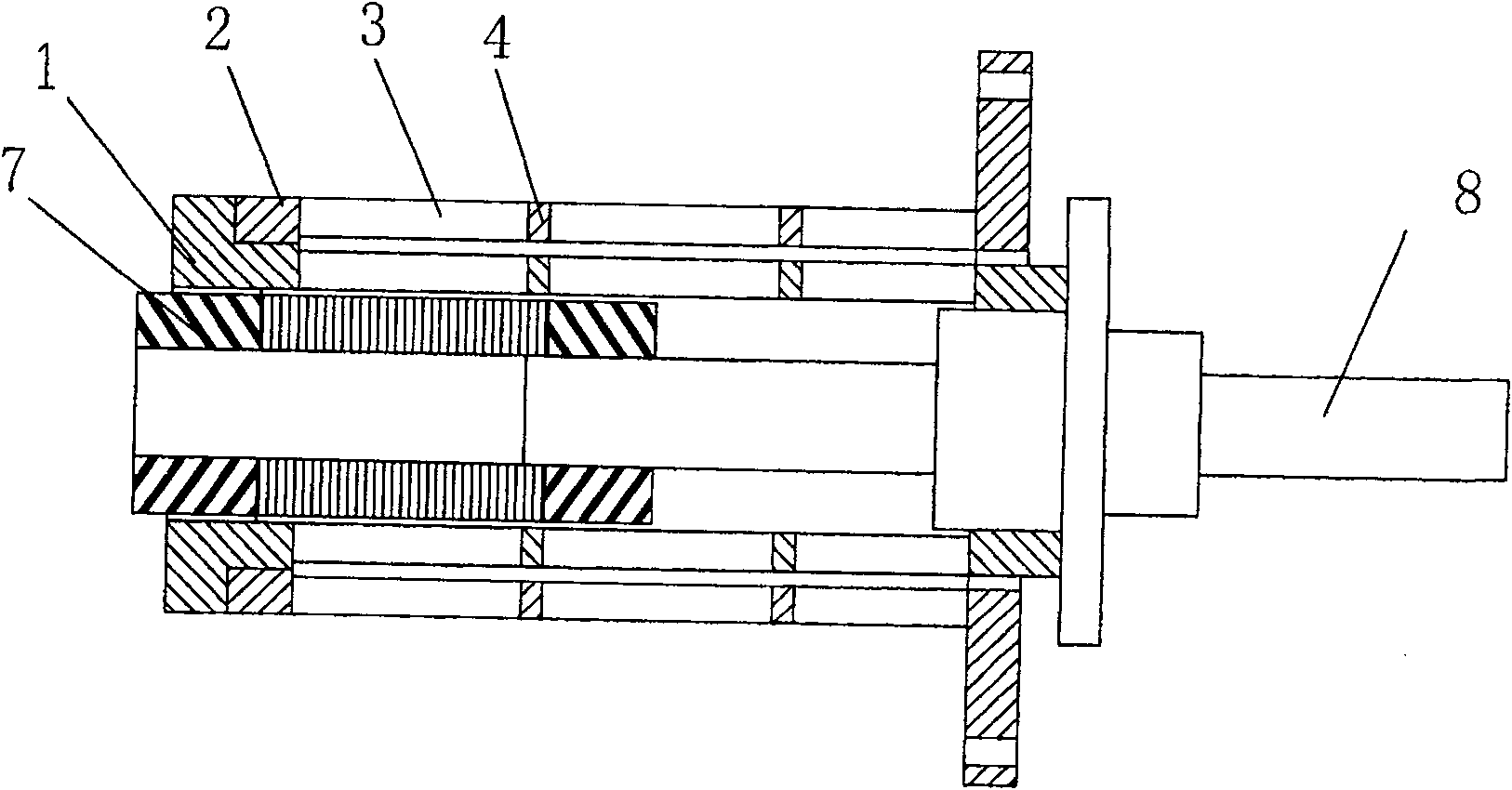

[0026] see figure 1 and figure 2 , the inner torsion tube 1 is coaxially nested in the outer torsion tube 2 and one end is fixedly connected. 2. It is composed of a plurality of identical outer torsion joints connected in series. The outer torsion joints are composed of a plurality of outer flexible sheets 3 that are uniformly distributed in the circumferential direction and arranged axially, and the radial plane is arranged between the outer annular connection entities 4. Each joint The number of the outer flexible sheets 3 of the outer torsion joint is an even number and arranged axially symmetrically in the circumferential direction. The inner torsion tube 1 is composed of a plurality of identical inner torsion joints connected in series before and after, and the inner torsion joints are composed of a plurality of inner flexible pieces 6 that are uniformly distributed along the circumferential direction and arranged axially, and arranged between the inner annular connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com