High-torque and large-stroke rotary actuator and method driven by piezoelectric stack and motor hybrid

A rotary actuator and hybrid drive technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. The motion output is powerless and other problems, to achieve the effect of high rotational motion actuation accuracy, easy processing and installation, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

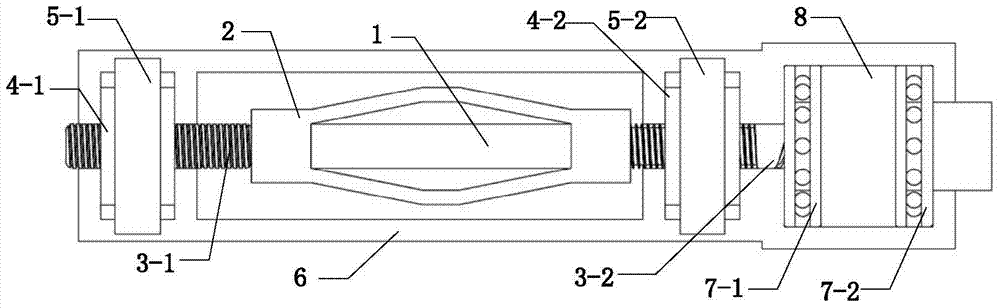

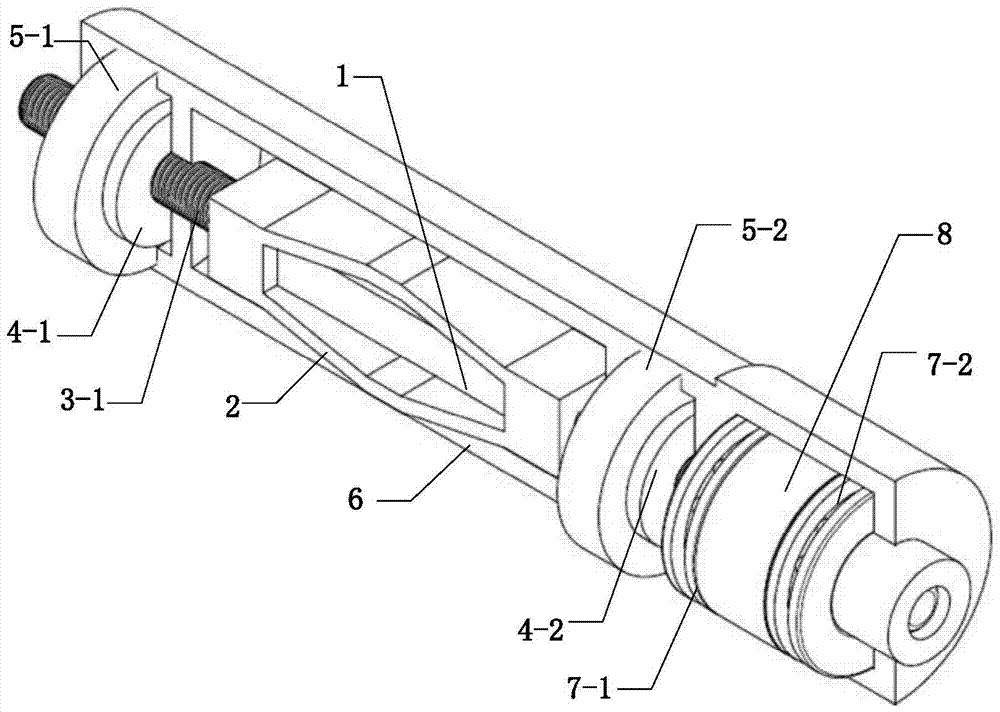

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0021] Such as figure 1 and figure 2 As shown, the high-torque and large-stroke rotary actuator driven by the piezoelectric stack and the motor hybrid of the present invention includes a rhombic ring 2, a piezoelectric stack 1 installed in the long axis of the rhombic ring 2, and a The first threaded connecting rod 3-1, the first lock nut 4-1 connected to the threaded connecting rod 3-1 through threads, and the first lock nut 4-1 is used as the rotor of the rotating mechanism, and the first drive is nested on the outside Stator 5-1; the second threaded connecting rod 3-2 connected to the other end of the long axis of the rhombic ring 2 with a large lead screw thread, and the second locking thread connected to the second threaded connecting rod 3-2 Nut 4-2, with the second lock nut 4-2 as the rotor, the second drive stator 5-2 is nested on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com