Single-frequency single-polarization liner cavity ytterbium-doping optical fiver laser

A ytterbium-doped fiber and linear cavity technology, applied in the field of single-frequency single-polarization linear cavity ytterbium-doped fiber laser, can solve the problems of reducing laser output power and the tuning range cannot be too wide, achieving low cost, avoiding diffraction loss, loss small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

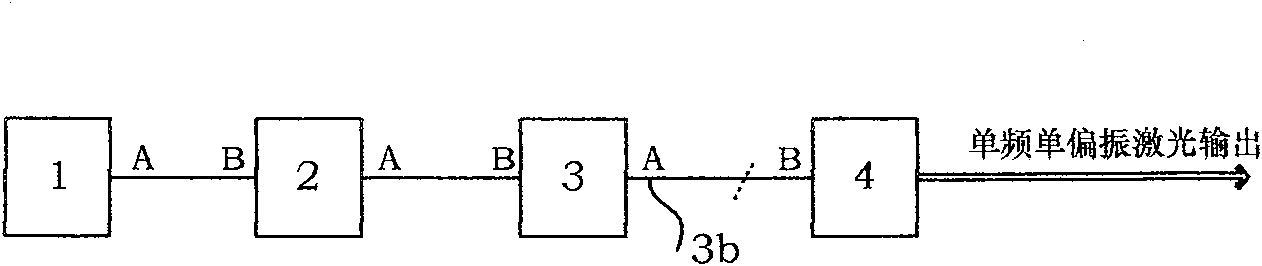

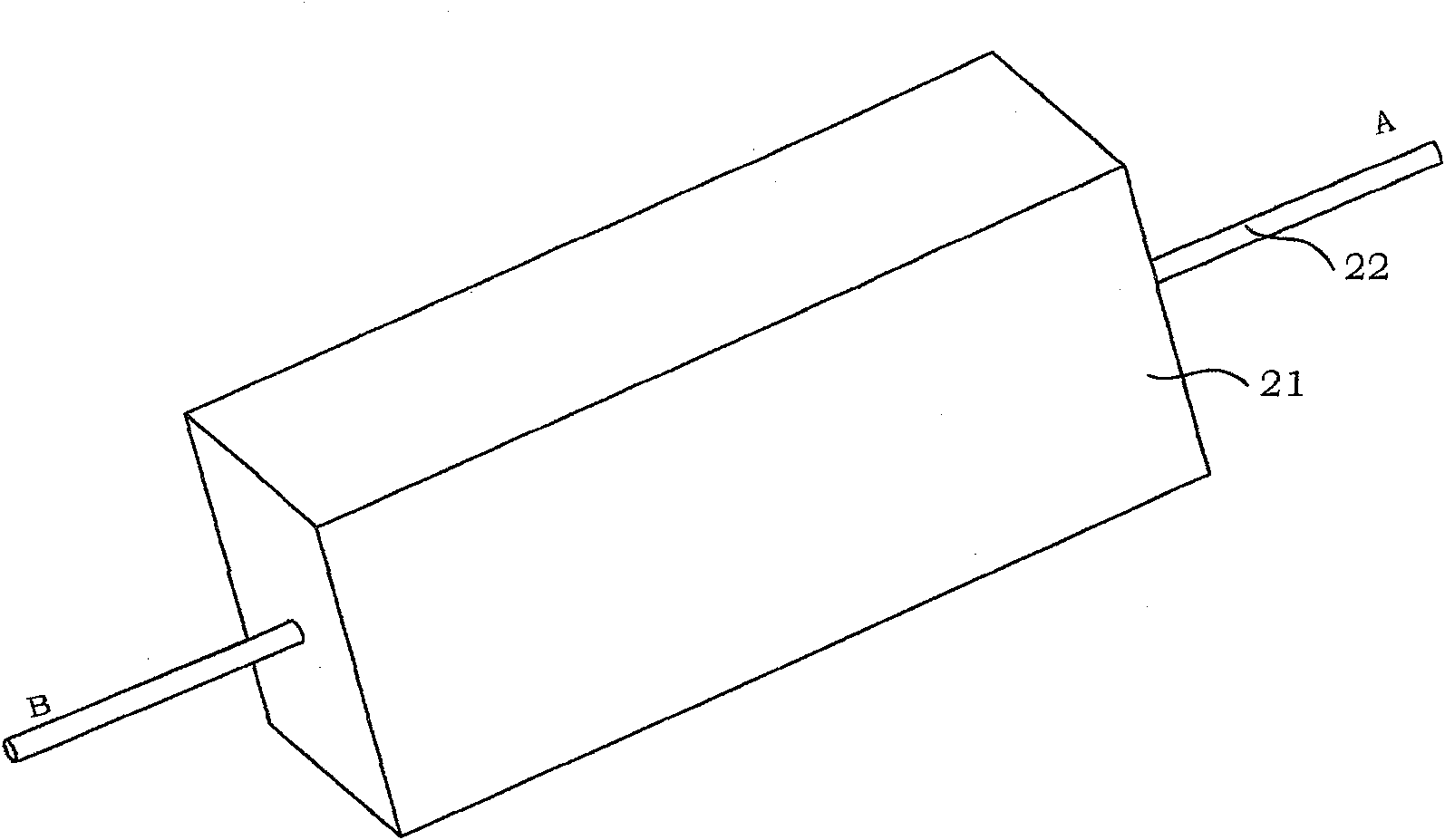

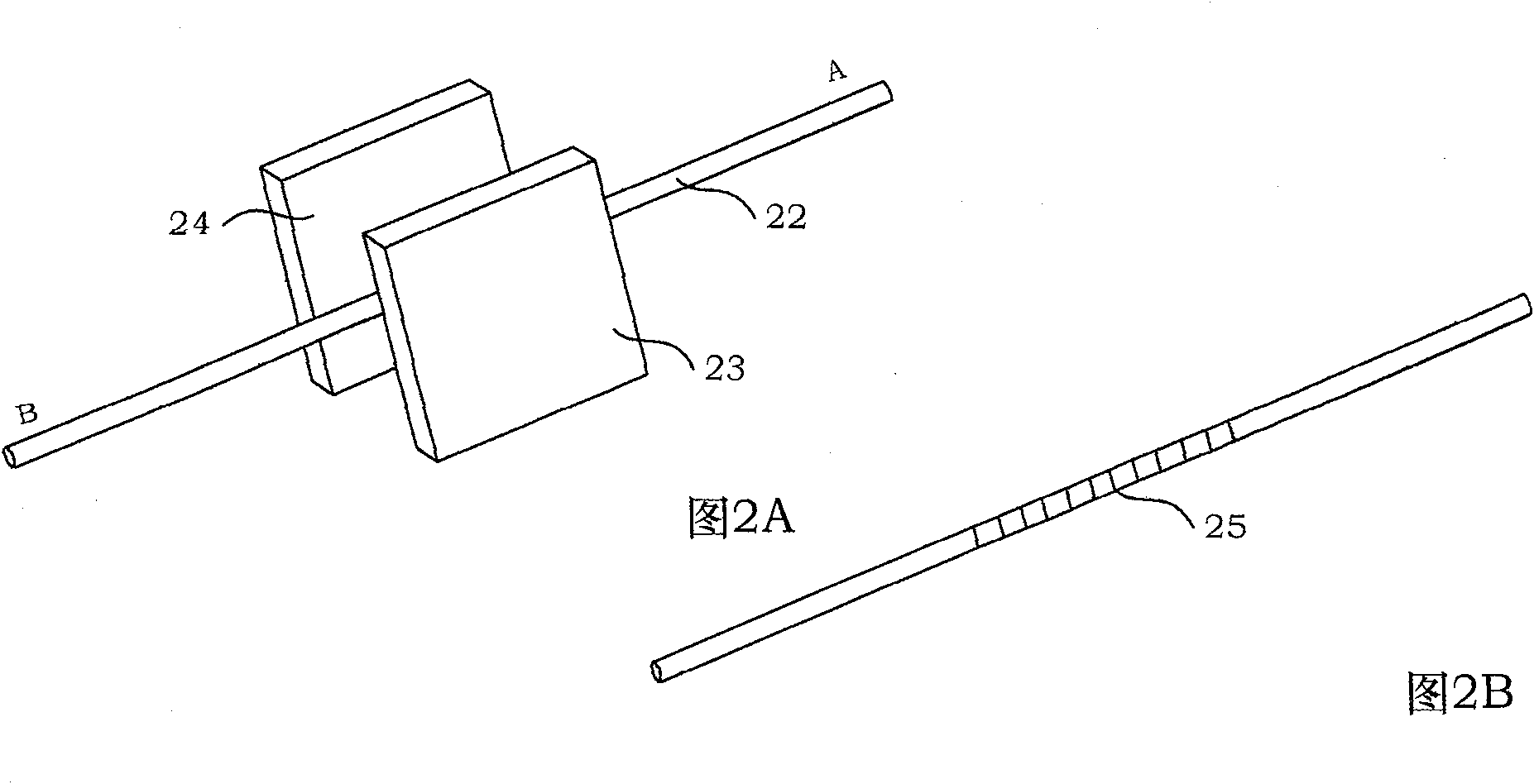

[0028] see figure 1 As shown, a single-frequency single-polarization linear cavity ytterbium-doped fiber laser of the present invention consists of a semiconductor laser pump source 1, a single-mode fiber grating component 2, a photosensitive stress birefringence ytterbium-doped polarization-maintaining fiber component 3 and a polarization-maintaining fiber 4 components, the A-end of the laser pump source 1 and the B-end of the single-mode fiber grating assembly 2 are welded by a single-mode fusion splicer, and the A-end of the single-mode fiber grating assembly 2 is connected to the photosensitive stress birefringence ytterbium-doped polarization-maintaining fiber assembly The B end of 3 is spliced by a single-mode fusion splicer, and the A end of the photosensitive stress birefringence Yb-doped polarization-maintaining fiber assembly 3 and the B-end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com