Hard-coated antiglare film, polarizing plate, image display, and method of manufacturing hard-coated antiglare film

A manufacturing method and anti-glare technology, applied in the direction of polarizing elements, coatings, nonlinear optics, etc., can solve the problem of not considering the surface roughness of the anti-glare hard coating, not satisfactorily solving the hardness and anti-glare, Unable to obtain sufficient hardness, etc., to achieve the effects of excellent anti-glare properties, excellent operability, and excellent display characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

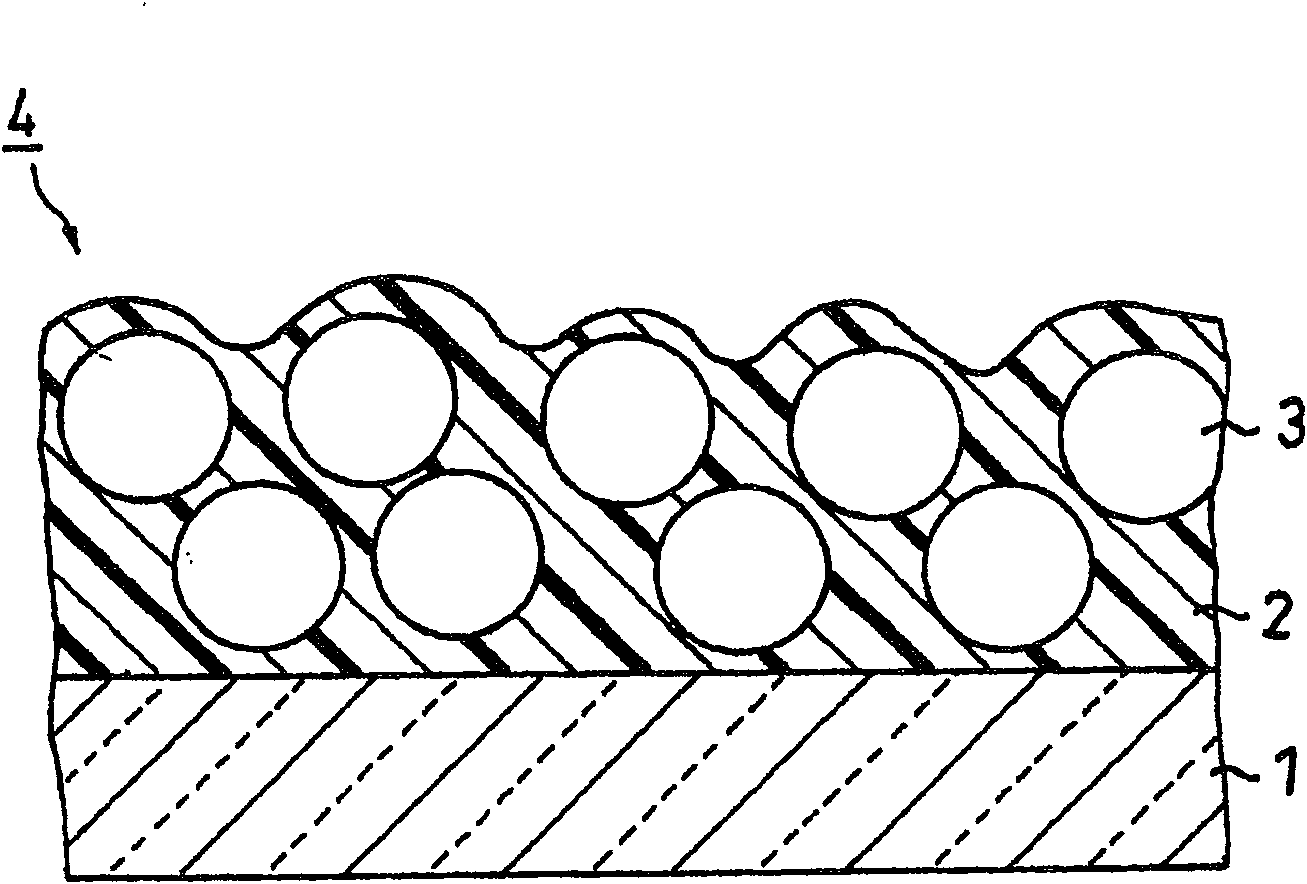

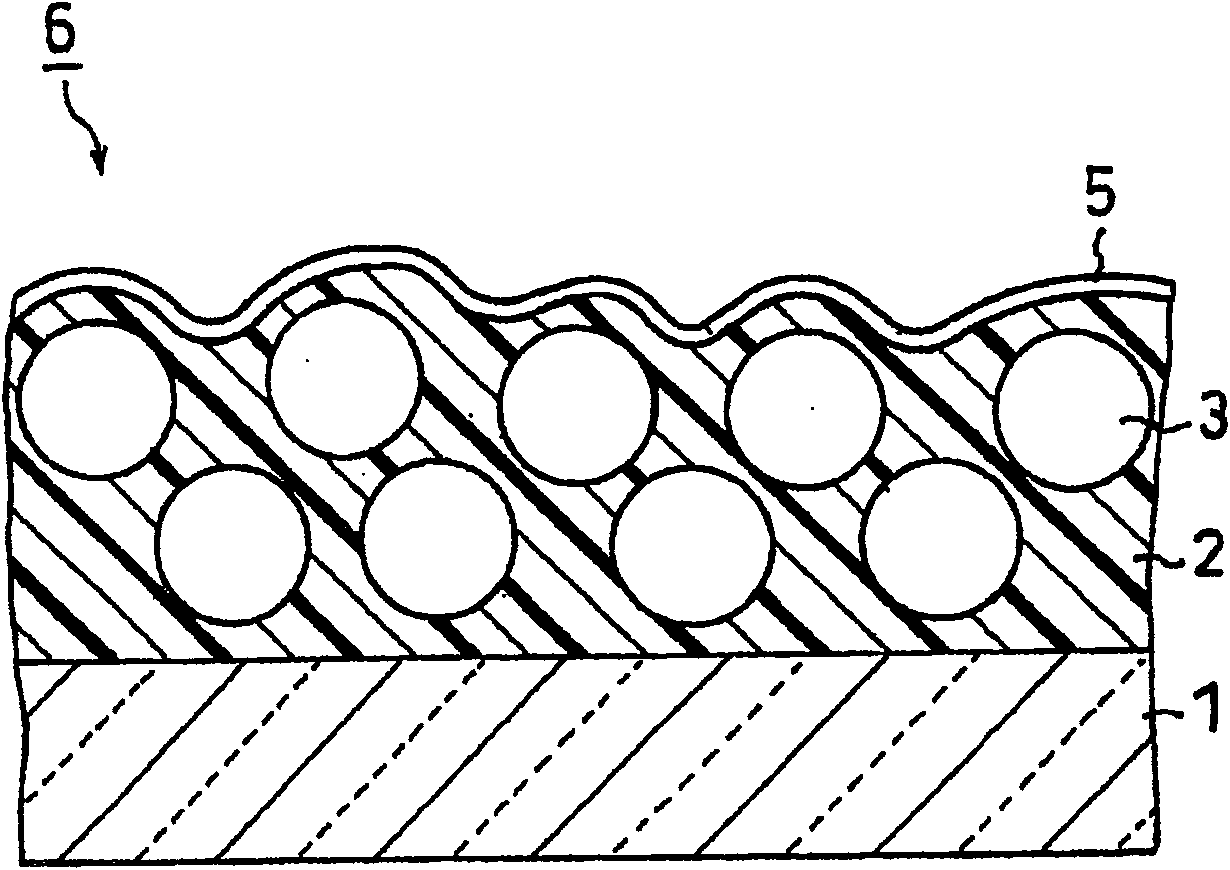

[0108] Prepare a resin raw material (66% by weight solid content concentration, manufactured by Dainippon Ink Co., Ltd., trade name: GRANDIC PC1097). The resin raw material contains the following components: (A), (B), (C), light Polymerization initiator and mixed solvent. To 100 parts by weight of the solid content of the resin raw material, 70 parts by weight of PMMA particles (manufactured by Sekisui Kasei Co., Ltd., trade name: MBX-8SSTN) with a weight average particle diameter of 8 μm and a leveling agent (manufactured by Dainippon Ink Corporation, product Name GRANDIC PC-F479) 0.1 parts by weight and mix. The mixture was diluted with a solvent (ethyl acetate) so that the solid content concentration would be 55% by weight, thereby preparing an antiglare hard-coat layer forming material. On a transparent plastic film substrate (triacetyl cellulose film with a thickness of 80 μm, refractive index: 1.48), the anti-glare hard coat forming material was applied using a #24 bar c...

Embodiment 2

[0115] Prepare a resin raw material (66% by weight solid content concentration, manufactured by Dainippon Ink Co., Ltd., trade name: GRANDIC PC1071). The resin raw material contains the following components: (A), (B), (C), light Polymerization initiator and mixed solvent. To 100 parts by weight of the solid content of the resin raw material, 50 parts by weight of PMMA particles (manufactured by Soken Chemical Co., Ltd., trade name: MX1000) with a weight average particle diameter of 10 μm and a leveling agent (manufactured by Dainippon Ink Corporation, trade name GRANDIC PC4-4133) 0.5 parts by weight and mixed. The mixture was diluted with a solvent (n-butanol) so that the solid content concentration was 35% by weight, thereby preparing an anti-glare hard-coat layer forming material. Except for using the aforementioned anti-glare hard coat forming material and using a #40 bar coater, the same operation and conditions as in Example 1 were used to produce an anti-glare hard coat ...

Embodiment 3

[0122] The same resin raw material as in Example 2 was used. To 100 parts by weight of the solid content of the resin raw material, 30 parts by weight of PMMA particles (manufactured by Soken Chemical Co., Ltd., trade name: MX1000) with a weight average particle diameter of 10 μm and a leveling agent (manufactured by Dainippon Ink Co., Ltd., trade name GRANDICPC4 -4133) 0.5 parts by weight and mix. The mixture was diluted with a solvent (cellosolve acetate) so that the solid content concentration was 35% by weight, thereby preparing an anti-glare hard-coat layer forming material. Except for using the aforementioned anti-glare hard coat forming material and using a #40 bar coater, the same operation and conditions as in Example 1 were used to produce an anti-glare hard coat film. The thickness of the anti-glare hard coating layer of the anti-glare hard coating film of this example was 25 μm. Most of the above-mentioned PMMA particles have an aspect ratio of less than 1.05.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com