Production of flax lignan

A technology of flax lignan and preparation process, which is applied to the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of high manufacturing cost, need for distillation and recovery, no technical problems, etc., and achieves shortening The effect of extraction man-hours, reduction of adsorption costs, and elimination of residual poisons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

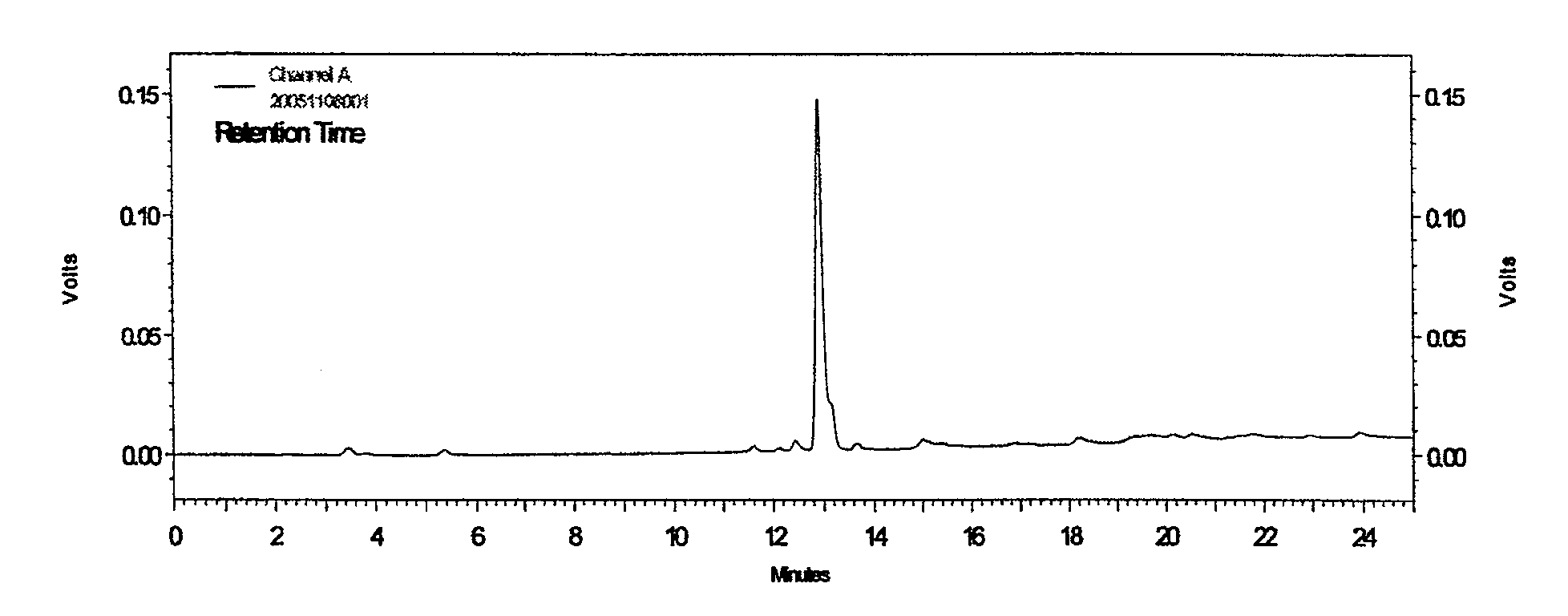

Image

Examples

Embodiment 1

[0039] a. Extraction: get 200 grams of linseed meal, use 2000 milliliters of 70% ethanol aqueous solution (wherein containing sodium hydroxide 2%) as extraction solvent, 60 ℃ for 5 hours, emit liquid. Supplementary leaching solvent 1000 milliliters, 60 ℃ 3 hours, release liquid. Add hydrochloric acid to adjust the pH to neutral (6.5-7.5). At 60-90°C and under a negative pressure of 0.6-0.9 MPa, distill and recover ethanol to obtain 800 ml of alcohol-free extract.

[0040] b. Extraction: Add ethyl acetate twice the volume of the alcohol-free extract, stir and let stand to separate layers, and take the water phase. Add one-fold volume of ethyl acetate to the water phase, stir and let stand to separate the layers, and take the water phase. Obtain 800 ml of crude extract of lignans.

[0041] C. Column: Add the crude extract to a macroporous resin chromatography column (resin model XAD-7HP). After the addition, the column was rinsed with deionized water until the effluent was c...

Embodiment 2

[0044] a. Extraction: take 500 grams of linseed meal, 5000 milliliters of extraction solvent [80% n-propanol aqueous solution (containing 8% sodium hydroxide)], leaching at 65 ° C for 5 hours, and release the liquid; add 2000 milliliters of extraction solvent , 65°C for 3 hours, the liquid was released. Add 20% aqueous sulfuric acid to adjust the pH to neutral (6.5-7.5). At 60-90°C and under a negative pressure of 0.6-0.9 MPa, distill and recover propanol to obtain 2000 ml of alcohol-free extract.

[0045] b. Extraction: Add butyl acetate twice the volume of the alcohol-free extract, stir and let stand to separate layers, and take the water phase. Add double the volume of butyl acetate to the water phase, stir and let stand to separate the layers, and take the water phase. Obtain lignans crude extract 2000 milliliters.

[0046] c. Column passing: the crude extract is added to a macroporous resin chromatography column (resin model SP70). After the addition, the column was w...

Embodiment 3

[0049] a. Extraction: Take 1000 grams of linseed meal, 10000 milliliters of extraction solvent [50% aqueous methanol solution (wherein containing potassium hydroxide 3%)] 10000 milliliters, leaching at 60 ℃ for 5 hours, release liquid; ℃ for 3 hours, the liquid was released. Add glacial acetic acid to adjust the pH to neutral (6.5-7.5). At 60-90°C, under a negative pressure of 0.6-0.9 MPa, distill and recover methanol to obtain 4500 ml of alcohol-free extract.

[0050] b. Extraction: Add diethyl ether to six times the volume of the alcohol-free extract, stir and let stand to separate layers, and take the water phase. Add three times the volume of diethyl ether to the water phase, stir and leave to separate layers, and take the water phase. Obtain lignans crude extract 4500 milliliters.

[0051]c. Column passing: the crude extract is added to a macroporous resin chromatography column (resin model XAD761). After the addition, the column was washed with 10% aqueous ethanol un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com