Method for preparing super metallurgy grade silicon

A metallurgical-grade silicon and ultrasonic technology, applied in the field of ultra-metallurgical-grade silicon, can solve the problems of increased difficulty in the purification process of metallurgical-grade silicon, and achieve the effects of low production costs, reduced production costs, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

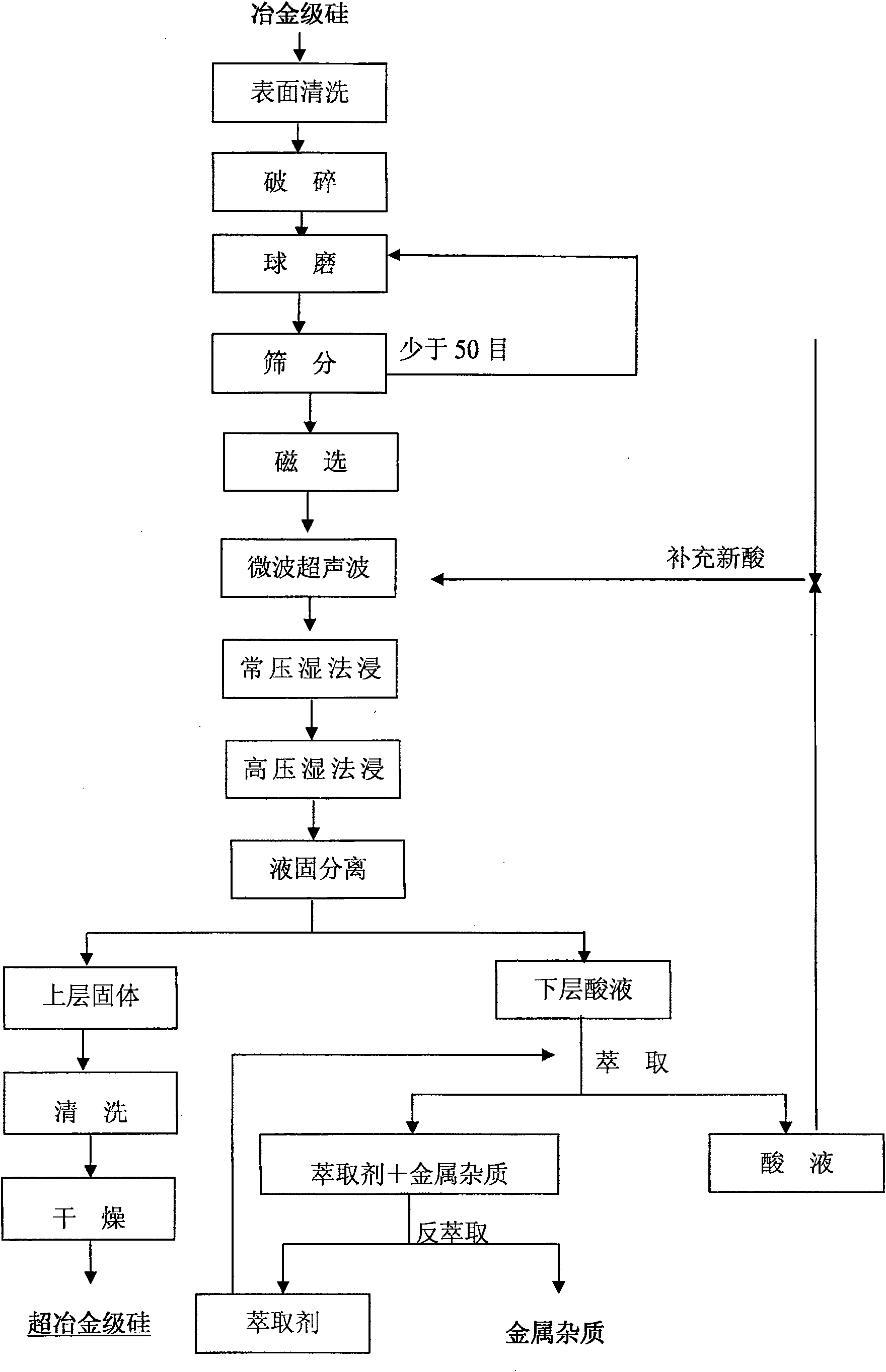

Image

Examples

Embodiment 1

[0033] Metallurgical grade silicon with a silicon content of 98.5wt% is used as a raw material, wherein the main impurity components include Al content of 1100ppmw, Fe content of 1620ppmw, and Ca content of 420ppmw.

[0034] The raw material is crushed by a crusher, ball milled by a ball mill, and the metallurgical grade silicon powder is screened by a sieving machine to obtain a silicon powder material with a particle size of 150 mesh, and then an electromagnetic separator is used to remove the iron brought in during the crushing and ball milling process. Impurities.

[0035]Use hydrochloric acid with a concentration of 4mol / L to react the silicon powder material under the action of ultrasonic waves with a power of 800W for 5 minutes according to the liquid-solid ratio of 1:1, and then carry out acid leaching treatment under the action of microwaves with a power of 300W for 60 minutes, and then remove it Place in a water bath at a temperature of 50°C for leaching for 5 days, ...

Embodiment 2

[0038] Metallurgical grade silicon with a silicon content of 99.5wt% is used as a raw material, and its main impurity components are Al content of 540ppmw, Fe content of 850ppmw, and Ca content of 200ppmw.

[0039] The raw materials are crushed by a crusher, ball milled by a ball mill, and the metallurgical grade silicon powder is screened by a sieving machine to obtain a silicon powder material with a particle size of 200 mesh, and then an electromagnetic separator is used to remove iron impurities brought in during the crushing and ball milling process .

[0040] Use nitric acid with a concentration of 8 mol / L to carry out acid leaching treatment on the silicon powder material according to the liquid-solid ratio of 5:1. First, treat it under the condition of ultrasonic power of 600W for 30min, then treat it under the condition of microwave for 40min, the microwave power is 600W, and then leaching in a water bath at 60°C for 3 days, then use vacuum filtration to separate the ...

Embodiment 3

[0043] Metallurgical grade silicon with a silicon content of 99.3wt% is used as a raw material, and its main impurity component A1 content is 930ppmw, Fe content is 1320ppmw, and Ca content is 420ppmw.

[0044] The raw material is crushed by a crusher, ball milled by a ball mill, and the metallurgical grade silicon powder is screened by a sieving machine to obtain a silicon powder material with a particle size of 100 mesh, and then an electromagnetic separator is used to remove iron impurities brought in during the crushing and ball milling process .

[0045] Use hydrochloric acid with a concentration of 3mol / L according to the liquid-solid ratio of 8:1 to treat the silicon powder material under ultrasonic conditions for 5 minutes, the power is 500W, and then treat it under microwave conditions for 120 minutes, the microwave power is 1000W, and then at 90 ° C leaching in a water bath for 2 days, and then use vacuum filtration to separate the acid solution from the material, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com