Environmental protection toilets for trains

A technology for trains and environmental protection, applied to railway car body components, sanitary equipment, household appliances, etc., can solve problems such as secondary pollution, toilet use restrictions, high cost, etc., achieve strong processing capacity, strong odor control, and low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

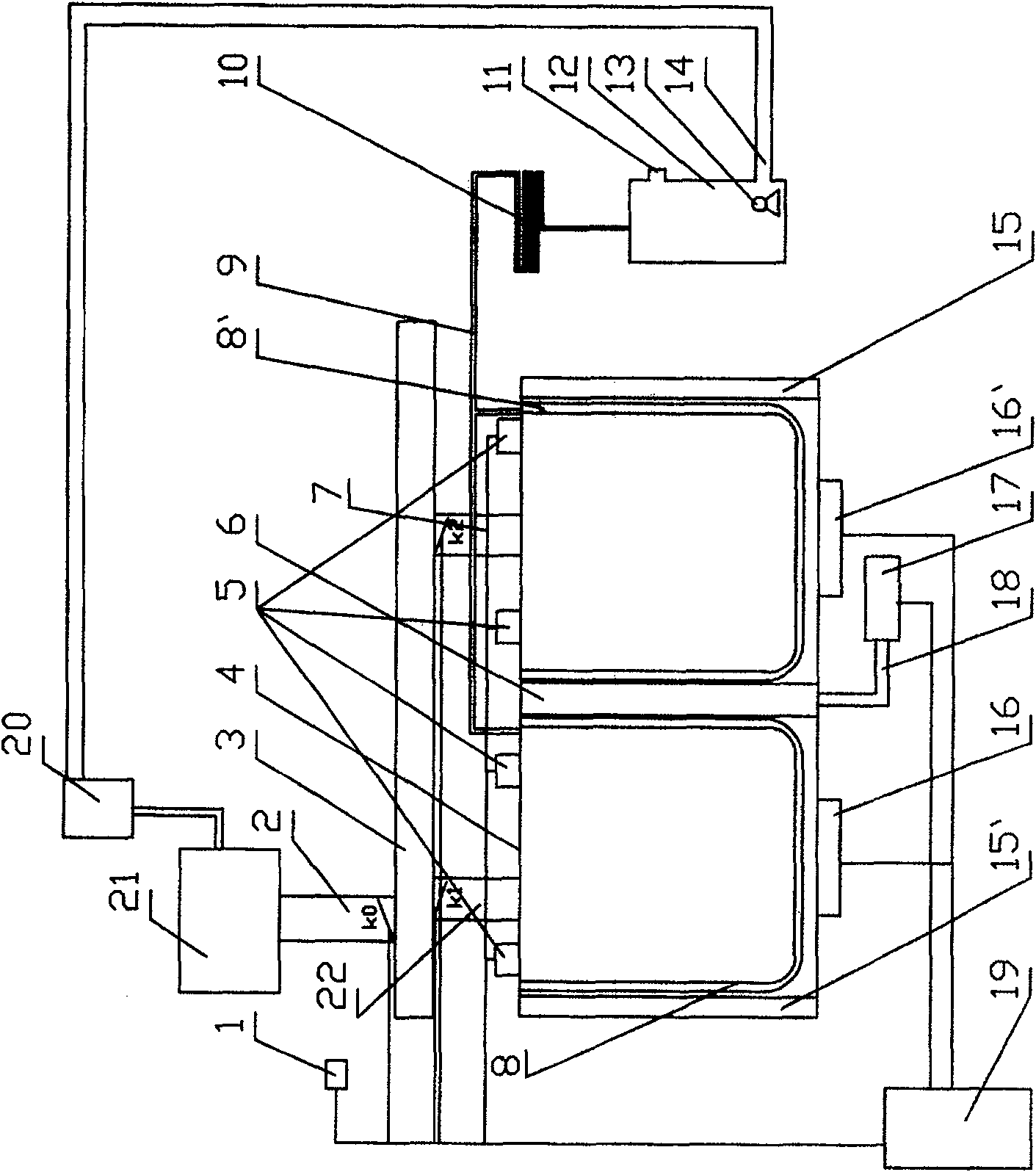

[0021] Embodiment: The train environment-friendly toilet as shown in the figure includes a toilet 21, a touch switch 1, a flush tank 20, a temporary storage box 3, a storage box 4 and a controller 19, and the touch switch 1 and the flush tank and the controller connected, the toilet 21 communicates with the temporary storage box 3 below it through the first pipeline 2, a first switch K0 is provided at the junction of the first pipeline 2 and the temporary storage box 3, and a switch K0 is arranged below the temporary storage box 3. Storage box 4 is arranged, and a dodge door 15, 15 ′ is respectively arranged on both sides of storage box 4. The temporary storage box 3 and the storage box 4 are connected through the second pipelines 22, 7, and the connection between the temporary storage box 3 and the pipelines 22, 7 is respectively provided with a second switch K1 and a third switch K2; and the second switch K1, The third switch K2 is connected with the controller. The storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com