Method for water soluble liquid state rubber foam forming stereo rubber product

A technology of liquid rubber and rubber products, which is applied in the fields of protective gear, water-soluble liquid rubber foam forming three-dimensional rubber products, and formed rubber insoles. It can solve problems such as lack of materials, insufficient tension, and no air permeability. Simple, good pulling effect and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

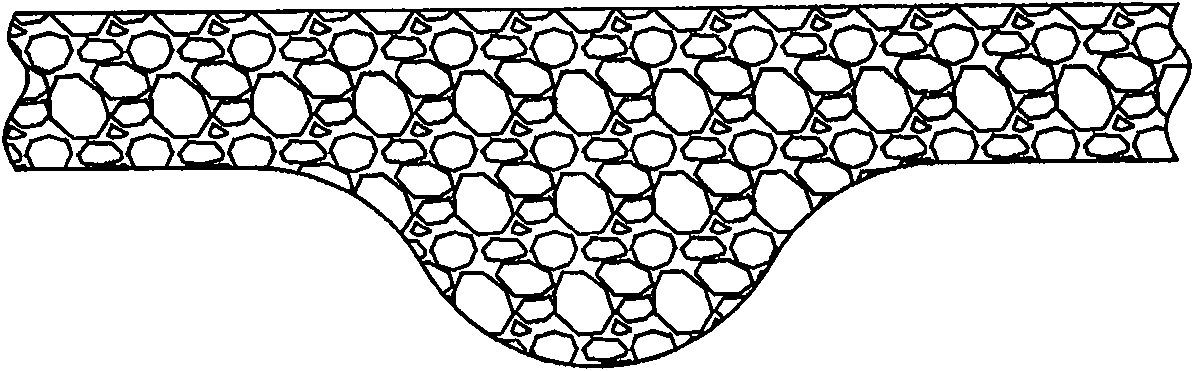

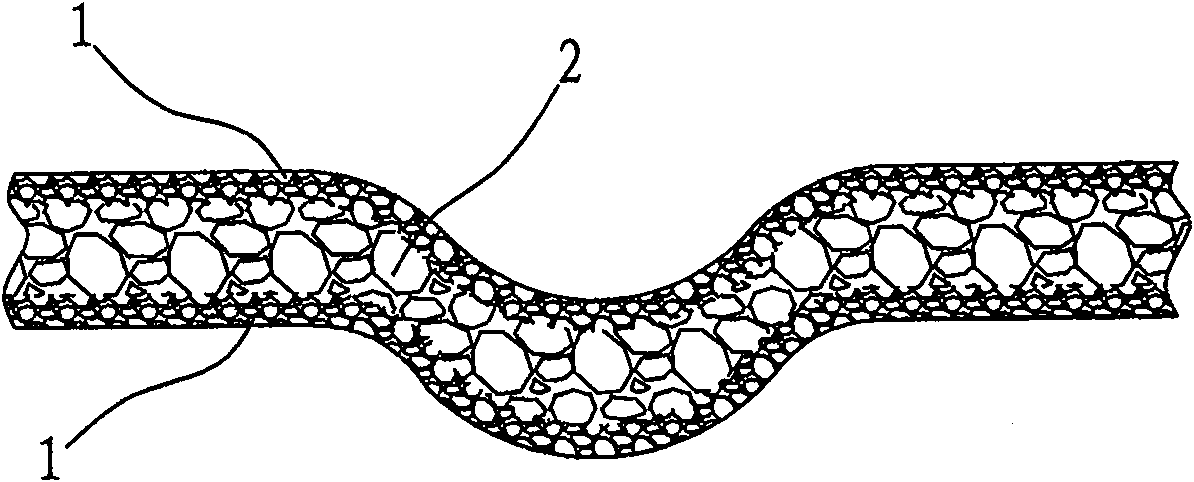

[0030] see figure 1 , figure 2 Shown, a kind of method of water-soluble liquid rubber foam molding three-dimensional insole, the steps are as follows:

[0031] ①Choose natural rubber liquid as the raw material of the insole, pour the liquid rubber after foaming into the pre-formed mold with different thicknesses, and set the thickness according to the thickness requirements of the designated parts required for forming the insole. Point thickness, so that the operation of the same thickness of the designated part can be formed according to the demand.

[0032] ② Bake the embryonic mold to make the bubble material (such as figure 1 (shown) shrinks slightly due to the disappearance of water. When the foamed liquid rubber is dried to the extent that it can be released from the mold and is not completely shaped, it can also make the air bubbles on the force-bearing surface in the subsequent pressurization in order to ensure stable dimensions. The technological process that will...

Embodiment 2

[0038] ①Choose natural rubber liquid as the raw material of the insole, pour the liquid rubber after foaming into the pre-formed mold with different thicknesses, and set the thickness according to the thickness requirements of the designated parts required for forming the insole. Point thickness, so that the operation of the same thickness of the designated part can be formed according to the demand.

[0039] ② Bake the embryonic mold to make the bubble material (such as figure 1 (shown) shrinks slightly due to the disappearance of water. When the foamed liquid rubber is dried to the extent that it can be released from the mold and is not completely shaped, it can also make the air bubbles on the force-bearing surface in the subsequent pressurization in order to ensure stable dimensions. The technological process that will produce the phenomenon of pushing, and then demoulding, and then make the dry insole embryos with different thicknesses;

[0040] ③Put the covering in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com