Heat exchanger, in particular a charge intercooler or coolant cooler for motor vehicles

A technology of heat exchangers, stiffeners, applied in the field of charge air cooler or coolant radiator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

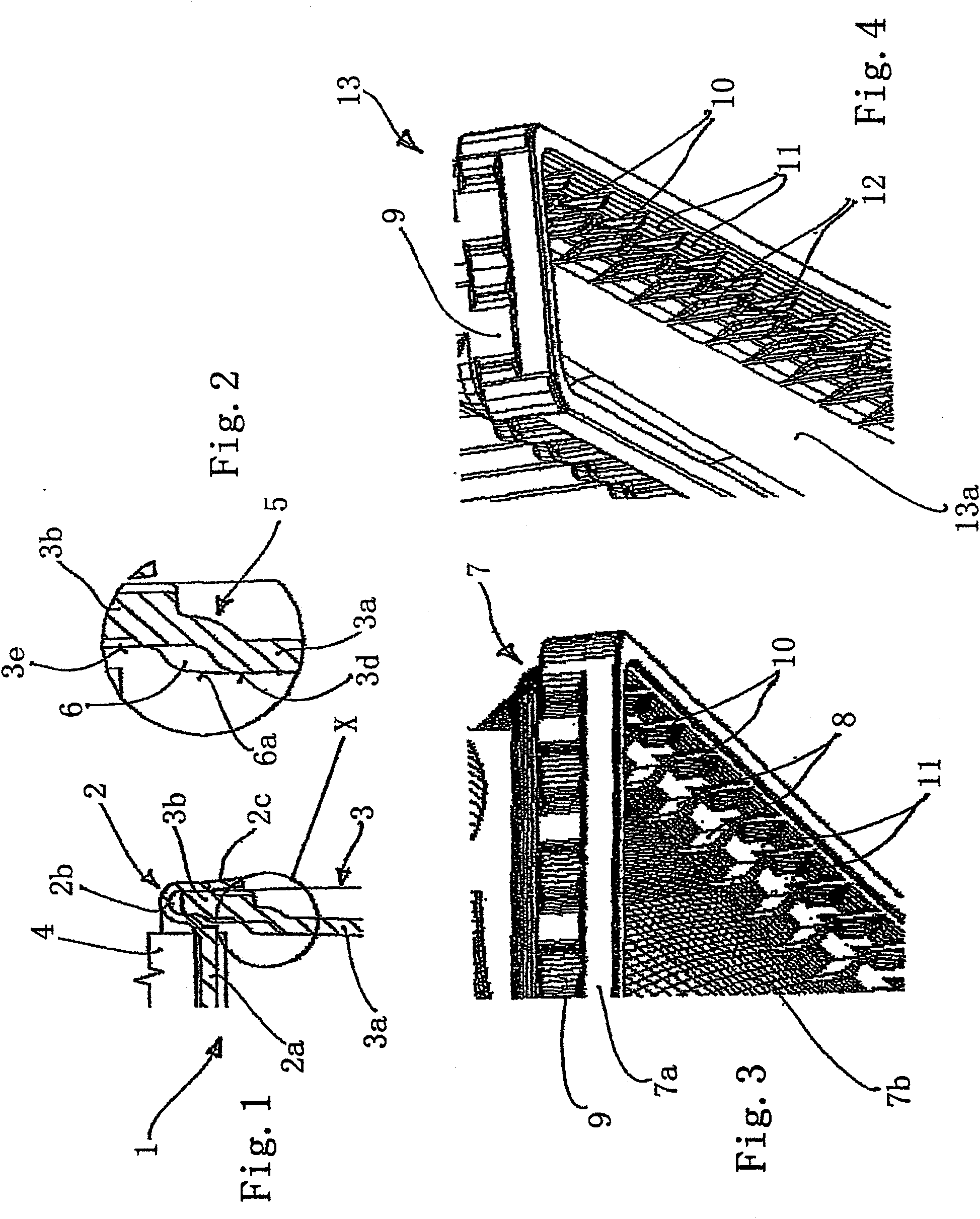

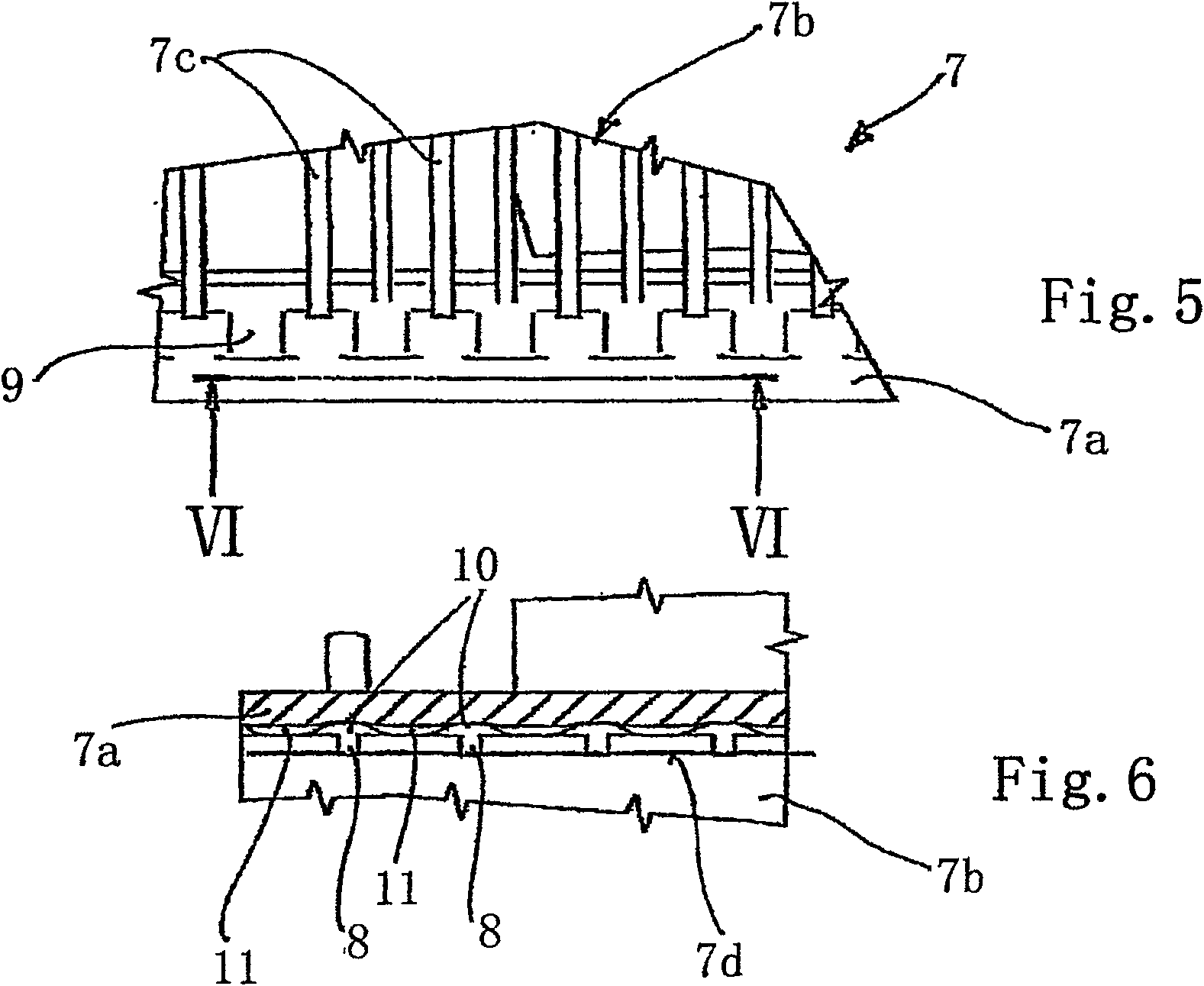

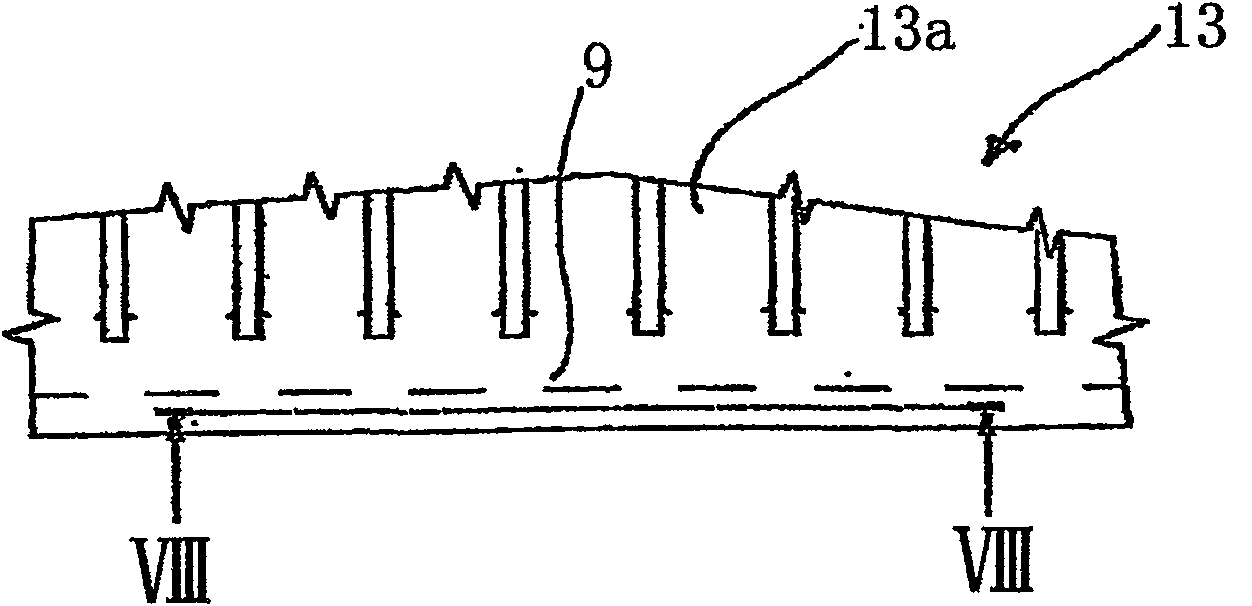

[0021] FIG. 1 shows a heat exchanger 1 according to the invention with a tube plate 2 , a plastic box 3 and flat tubes 4 which are fastened in openings 2 a of the tube plate 2 . As is known from the prior art, the tube base 2 has on the outside a circumferential groove 2b, to which an outer edge region 2c adjoins. The plastic box 3 has a U-shaped profile, not fully shown, which comprises a wall 3a which transitions into a thicker-walled flange 3b. Flange 3b with a seal (not shown) is inserted into groove 2b of tube base 2 and clamped to tube base 2 via deformable edge region 2c in a crimping or clamping connection (not shown in detail). Such a tank / tube-sheet connection is known from the aforementioned prior art, for example DE-A 38 41 470 . The flat tube 4 is brazed with corrugated fins not shown in the figure and the opening on the tube plate (only part of the tube plate 2 can be seen in the tube plate) to form a core body. The plastic box (in which again only a section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com