High-rigidity beam structure

A beam structure, high rigidity technology, applied in the direction of structural elements, elongated structural members for load-bearing, truss-type structures, etc., can solve problems such as insufficient beam rigidity, reduce static deformation of the structure, simple structure, and convenient transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

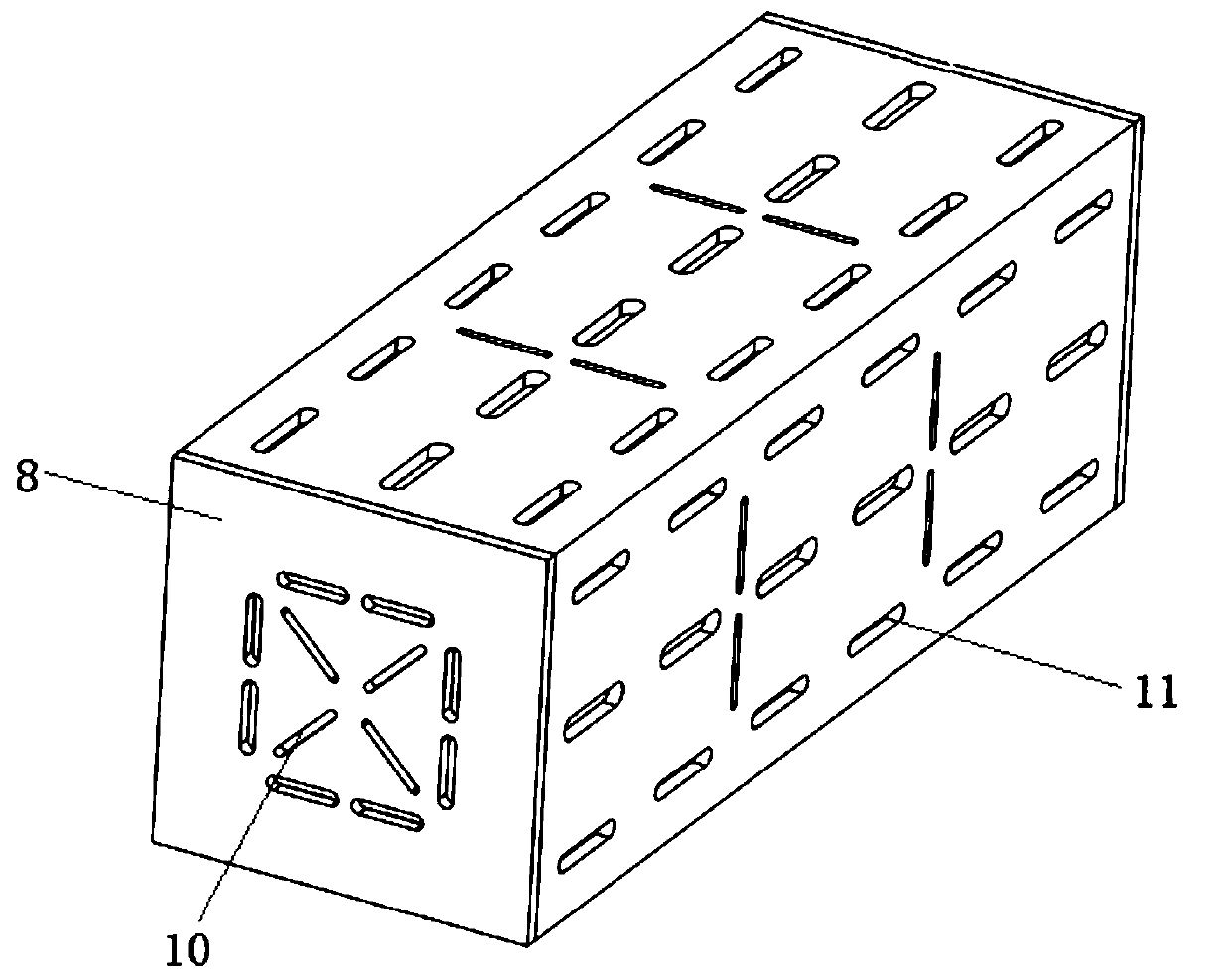

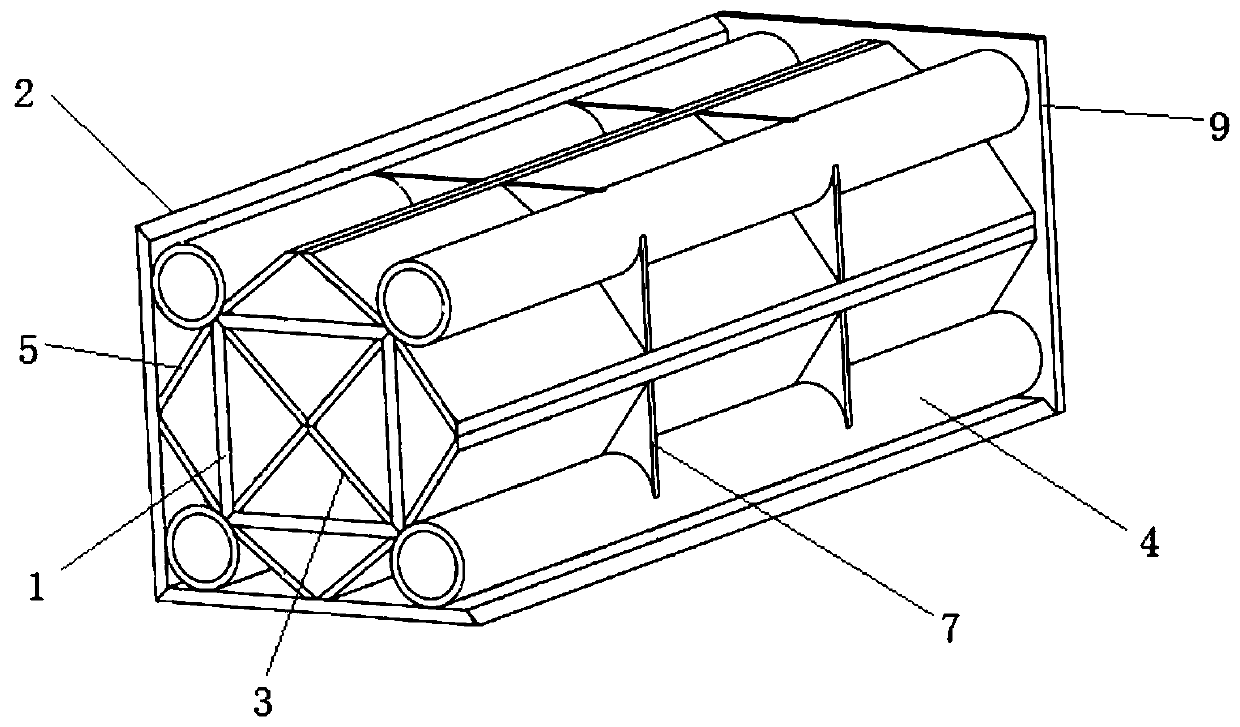

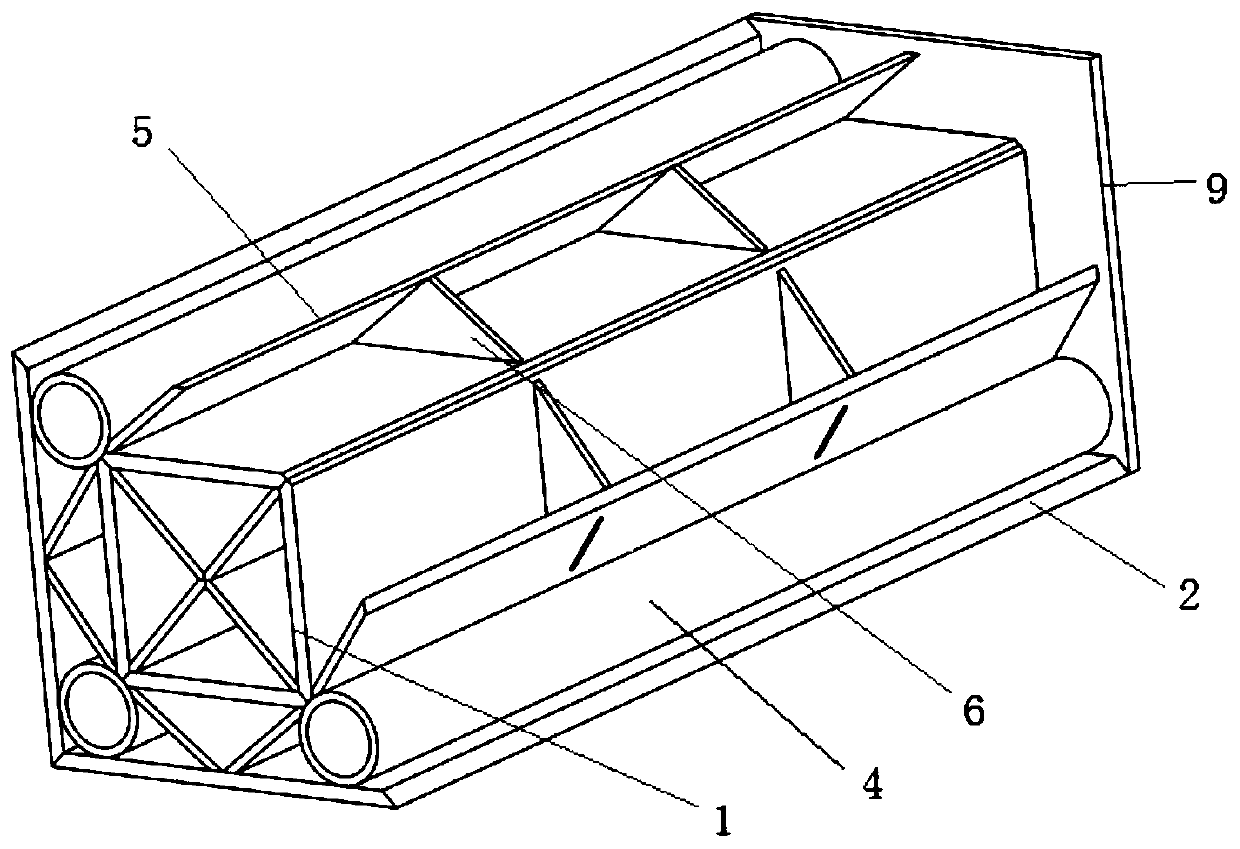

[0021] Such as Figure 1 to Figure 3 As shown, a high-rigidity beam structure of the present invention comprises a central beam 1 formed by four groups of flat plates connected end to end by sequential welding to form a square cross section and an outer frame 2 formed by four groups of side plates connected by end to end sequentially welded to form a square cross section. The beam 1 is located inside the outer frame 2 and the center beam 1 and the outer frame 2 form a back-shaped structure. The side edges of the center beam 1 are respectively welded with a center plate 3 extending toward the center line of the center beam 1. There are four sets of center plates 3. The center plate 3 intersects at the centerline of the center beam 1 and is fixed by welding. An angle tube 4 is welded between the side edge of the center beam 1 and the inner side wall of the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com