Construction method for spiral auger central pump injection superflowing concrete screw pile and device for fabricating screw thread of the pile

A technology of auger rod and construction method, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of difficult synchronization, difficult to form threads, unable to form threads, etc., achieving good pile forming effect and increasing side The effect of friction resistance and low renovation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

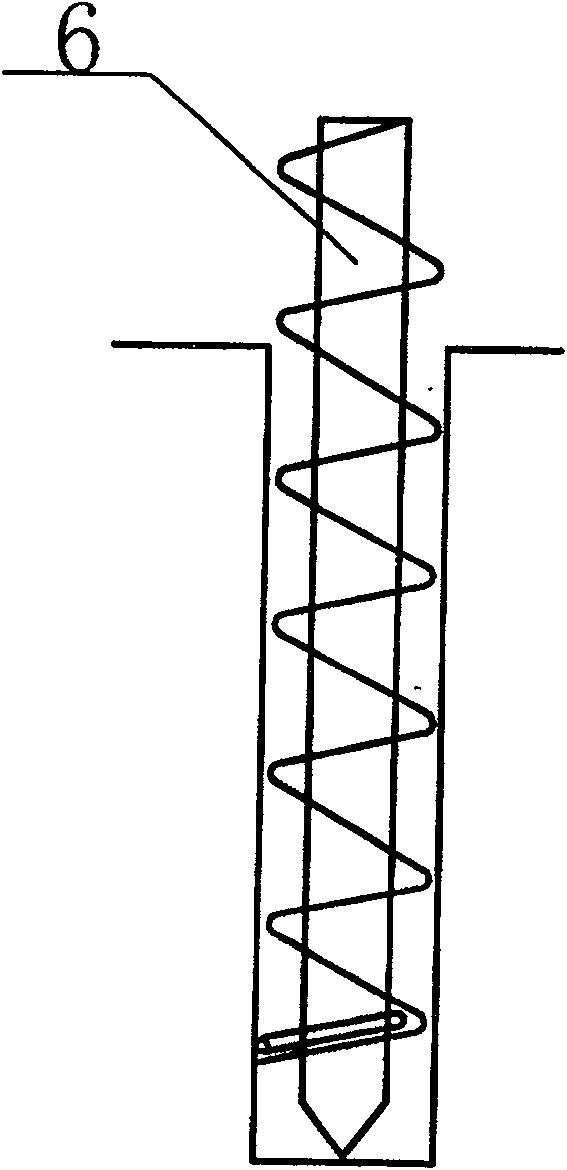

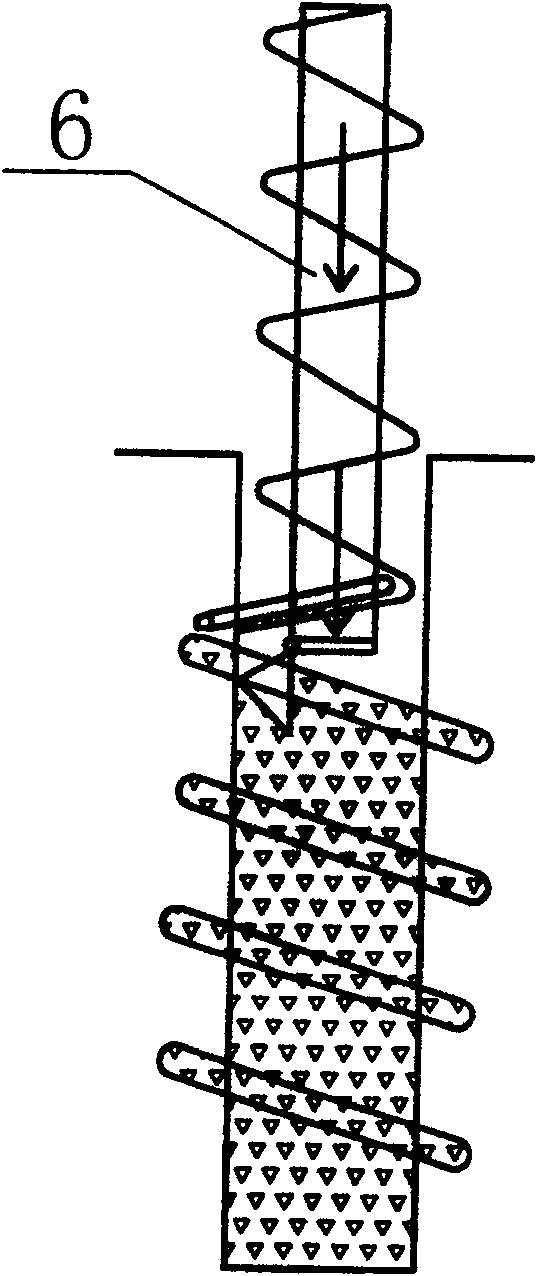

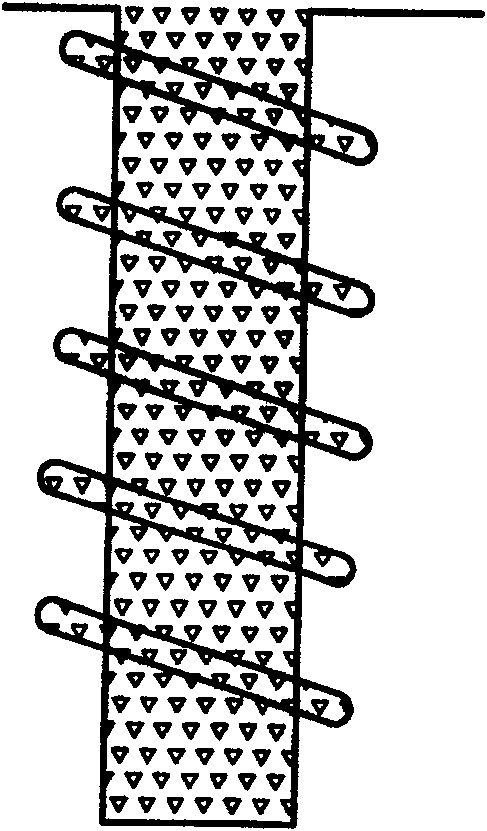

[0021] The construction method of superfluid concrete threaded piles with center pumping of auger drill rods. First, a long auger drill with a thread making device is used to drill to the design depth, and then the hydraulic jack is started to extend the thread maker, and at the same time, the drill pipe is reversed and lifted. When the drill pipe is raised, superfluid concrete is poured through the hollow of the drill pipe, and finally the drill pipe is pulled out and then inserted into a reinforcement cage.

Embodiment 2

[0023] The thread making device described in embodiment 1, its composition comprises: the end portion of the auger rod 6 of a common long auger drilling machine has a drill bit 5, a hydraulic jack 3, a thread maker 2 and a fixing member 1, and the auger rod is hollow Drill pipe, the hydraulic jack 3 is located on the helical blade 4 at the bottom of the auger drill pipe, and the thread maker 2 is located at the end of the hydraulic jack 3 .

Embodiment 3

[0025] In the construction method of threaded piles with superfluid concrete injected into the center of the auger drill pipe described in embodiment 1, the superfluid concrete is concrete with a slump of 18cm-24cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com