Electric spanners

A motor-driven, pawl technology, applied in the field of electric wrench, can solve the problems of non-adjustable impact torque, no overload protection, low impact torque, etc., to achieve the effect of improved impact torque, reliable action, and large impact torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

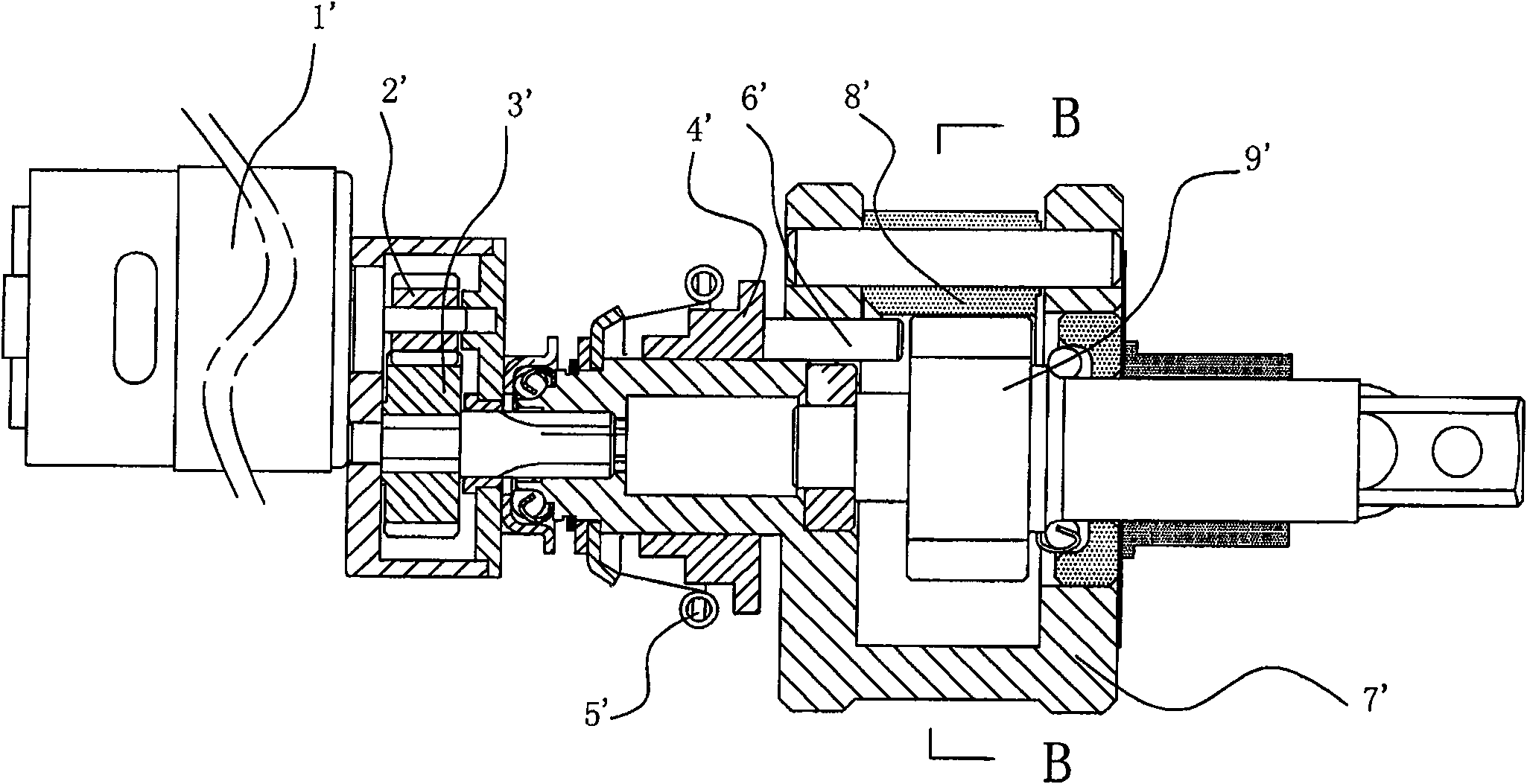

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

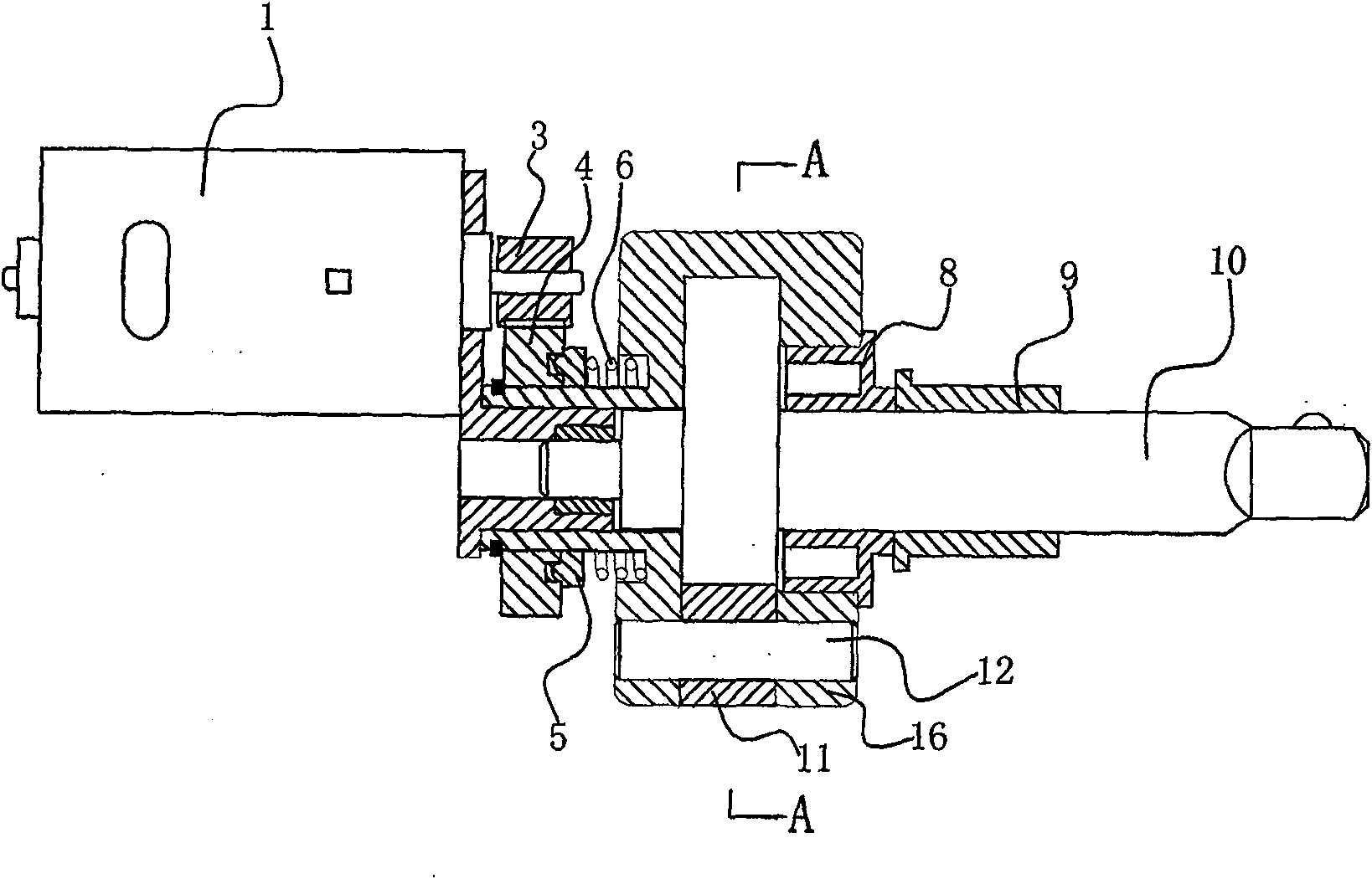

[0013] Such as figure 1 with figure 2 As shown, the electric wrench includes a motor 1, a pinion 3 driven by the motor 1, a large gear 4 meshing with the pinion 3, a clutch 5 is movably embedded in the large gear, and the clutch spring 6 is set against the Between ratchet seat 16 and clutch 5.

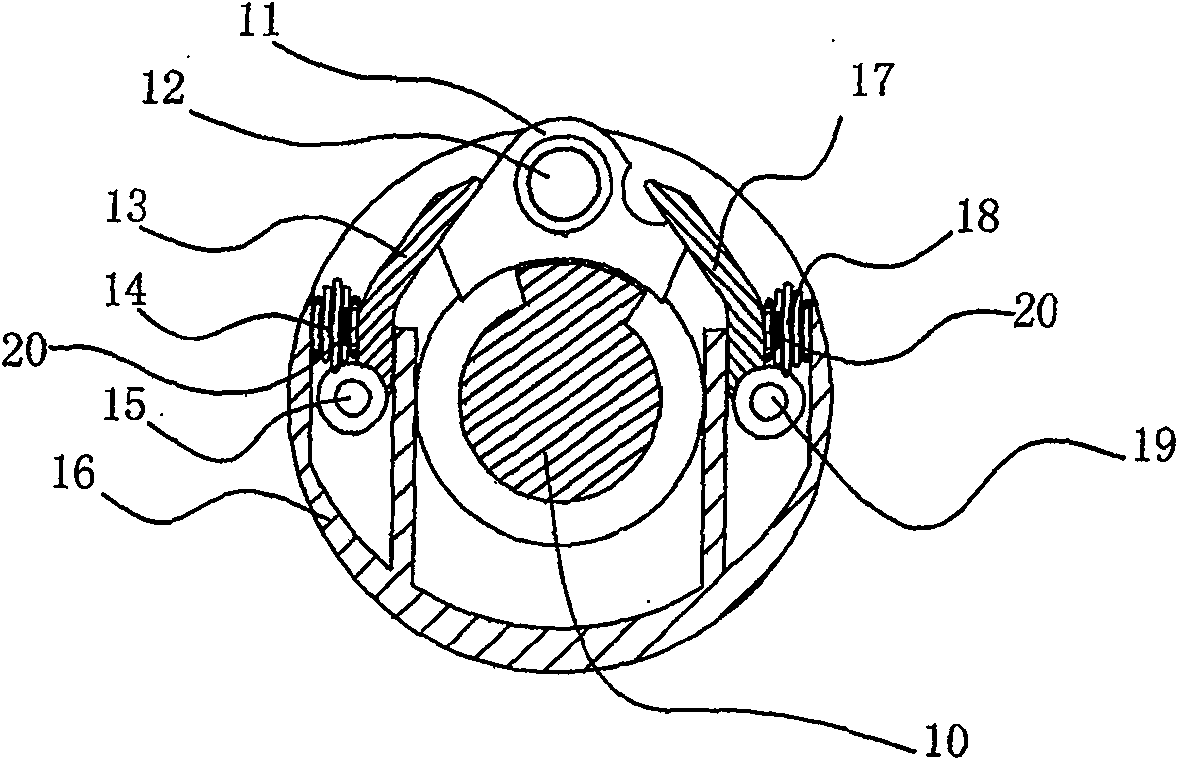

[0014] Such as figure 2 As shown, the ratchet 10 is located at the central position of the ratchet seat 16, and its two sides respectively have an inner limit plate 8 and an outer limit plate 9 on the ratchet seat 16, and the left cylindrical pin 15 and the right cylindrical pin 19 are fixed respectively. Located on both sides of the ratchet seat 16 and between the inner limit plate 8 and the outer limit plate 9, the ratchet 11 is pivotally connected to the ratchet seat 16 through a large cylindrical pin 12; the left pawl pressing plate 13 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com