Composition and foods for lowering glycemic index

A technology of glycemic index and composition, which is applied in the field of low glycemic index foods and compositions for lowering the glycemic index to achieve the effect of preventing the onset of diabetes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

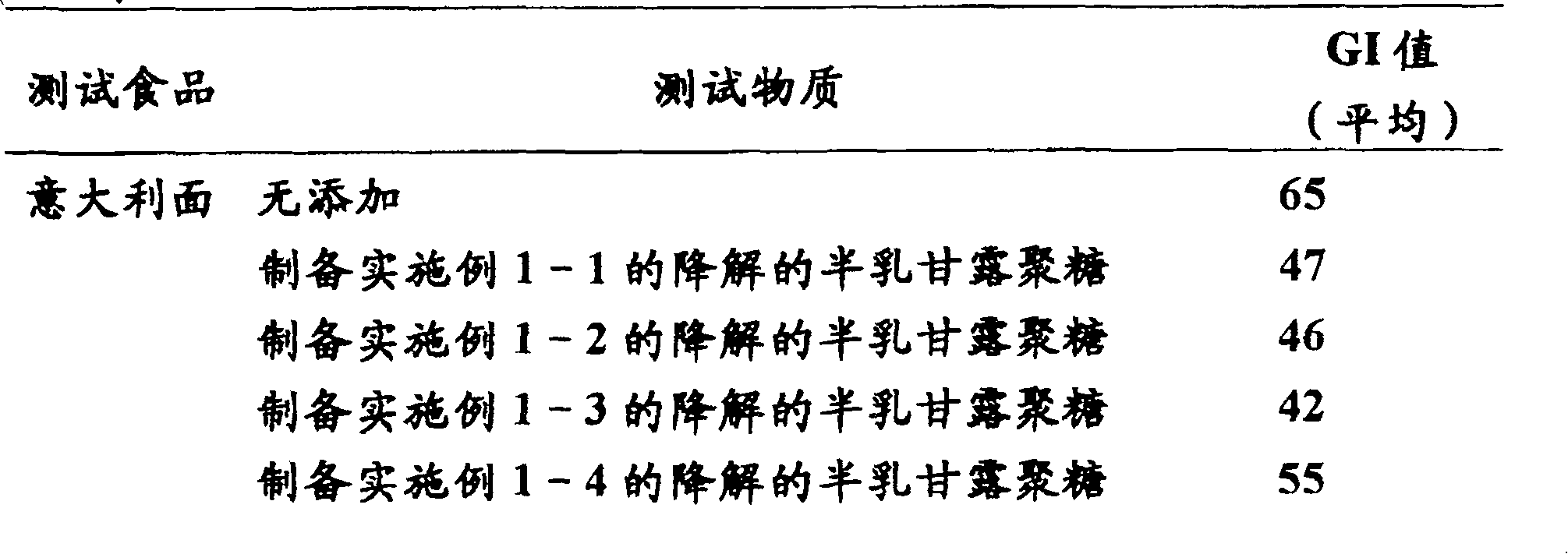

preparation Embodiment 1-1

[0124] Add 0.1N hydrochloric acid to 900g of water to adjust the pH to 4.5. 0.2 g of β-mannanase (produced by Novo Nordisk Bioindustry) and 100 g of guar gum powder (produced by Novo Nordisk Bioindustry) from microorganisms of the genus Aspergillus were added thereto, and the mixture was mixed uniformly at 40 The enzymatic hydrolysis of guar gum was carried out from °C to 45 °C over a period of 24 hours. After the reaction, the mixture was heated to 90° C. for 15 minutes to inactivate the enzyme. The mixture was separated by filtration (suction filtration), and insoluble materials were removed. The resulting clear solution was concentrated under reduced pressure (Yamato evaporator) (solid content: 20% by weight), and then the concentrate was dried with a spray dryer [manufactured by Ohkawara Kakouki Co., Ltd.] to obtain 65 g of degraded powder in the form of galactomannan (degraded galactomannan content: 90% by weight). Here, the degraded galactomannan contained protein in a...

preparation Embodiment 1-2

[0127]Add 0.1N hydrochloric acid to 900g of water to adjust the pH to 3. Add 0.15 g of β-mannanase (produced by Novo Nordisk Bioindustry) and 100 g of guar gum powder (by Taiyo Kagaku Co., Ltd., high-quality product) from Aspergillus microorganisms thereto, mix the mixture, and mix the mixture at 40 The enzymatic hydrolysis of guar gum was carried out from °C to 45 °C over a period of 24 hours. After the reaction, the mixture was heated to 90° C. for 15 minutes to inactivate the enzyme. The mixture was separated by filtration (suction filtration) to remove insoluble material. The resulting clear solution was concentrated under reduced pressure (Yamato evaporator) (solid content: 20% by weight), and then the concentrate was dried with a spray dryer [manufactured by Ohkawara Kakouki Co., Ltd.] to obtain 68 g of degraded powder in the form of galactomannan (degraded galactomannan content: 85% by weight). Here, the degraded galactomannan contained protein in an amount of 4.1% b...

preparation Embodiment 1-3

[0130] Add 0.1N hydrochloric acid to 900g of water to adjust the pH to 4. Add 0.25 g of β-mannanase (produced by Novo Nordisk Bioindustry) and 100 g of guar gum powder (by Taiyo Kagaku Co., Ltd., high-quality product) from Aspergillus microorganisms to which, mix the mixture, at 50 The enzymatic hydrolysis of the guar gum was carried out from °C to 55 °C over a period of 12 hours. After the reaction, the mixture was heated to 90° C. for 15 minutes to inactivate the enzyme. The mixture was separated by filtration (suction filtration) to remove insoluble material. The resulting clear solution was concentrated under reduced pressure (Yamato evaporator) (solid content: 20% by weight), and then the concentrate was dried with a spray dryer [manufactured by Ohkawara Kakouki Co., Ltd.] to obtain 70 g of degraded powder in the form of galactomannan (degraded galactomannan content: 80% by weight). Here, the degraded galactomannan contained protein in an amount of 6.7% by weight.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com