Micro-reaction device and method for synthesizing cadmium selenide nano-crystal by using temperature gradient

A micro-reaction device and temperature gradient technology, applied in the field of micro-chemical machinery and nano-materials, can solve the problems of poor precision, out-of-control nanocrystal growth process, reduction, etc., to improve yield and quality, large-scale production satisfaction, and flexible implementation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

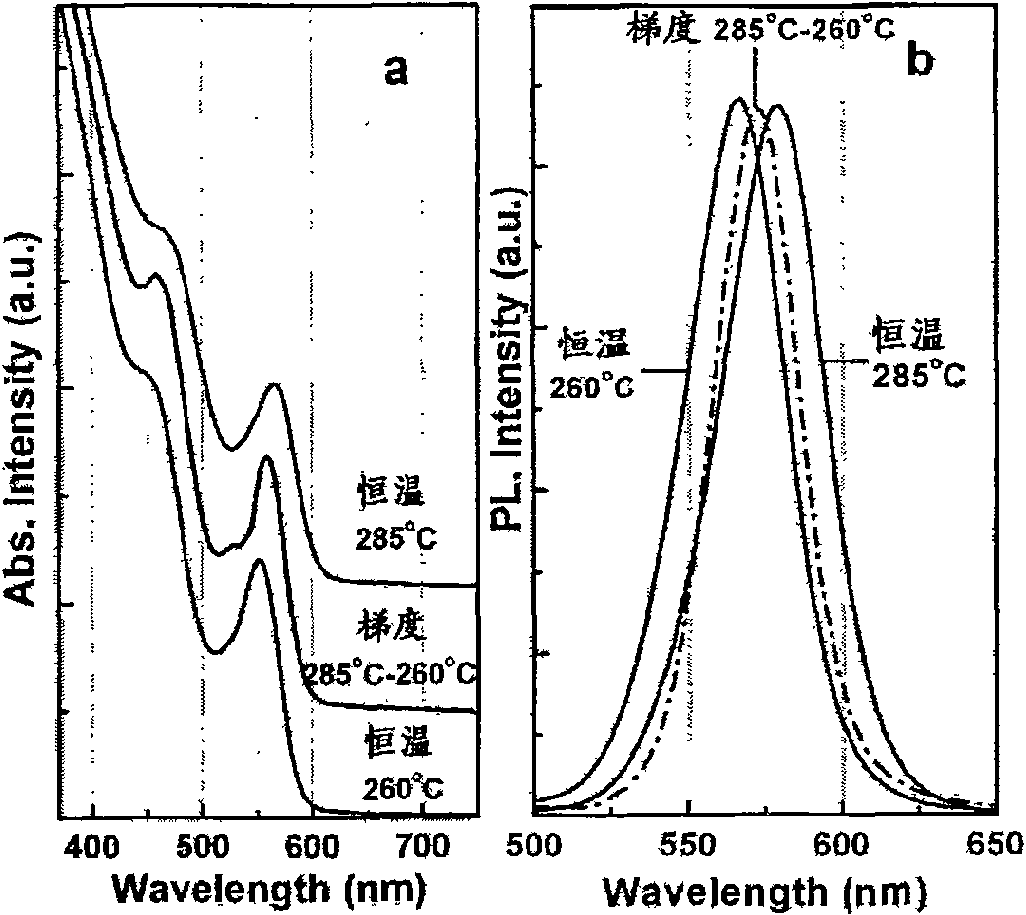

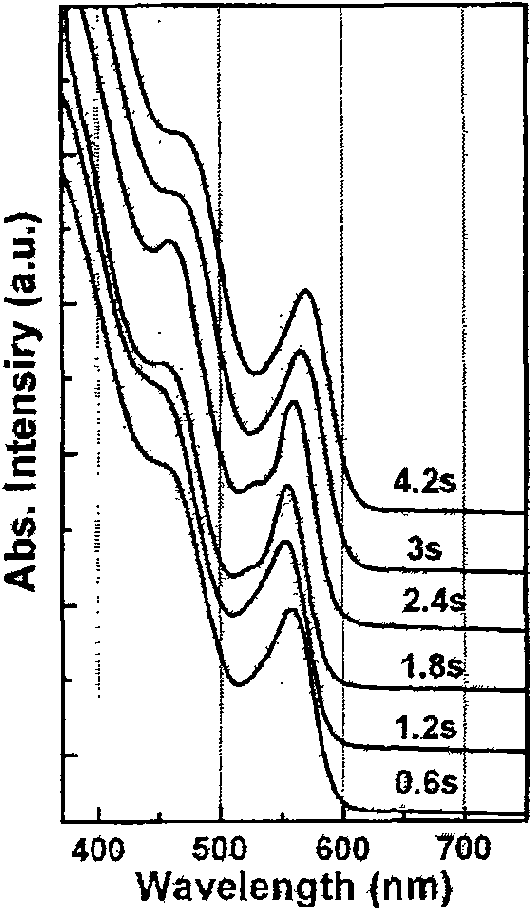

[0035] (1) A mixture of 17.13mg CdO, 0.47ml oleic acid and 3.53ml octadecene was heated at 150°C for 1.5 hours to obtain a transparent solution as a Cd precursor; Se (52.67mg) was dissolved in 1.5ml tri-n-octylphosphine , the obtained transparent solution was diluted to 4 ml with octadecene and oleylamine to obtain the Se precursor. The two precursors were degassed at 100 °C for 1 hour and loaded into tightly sealed syringes;

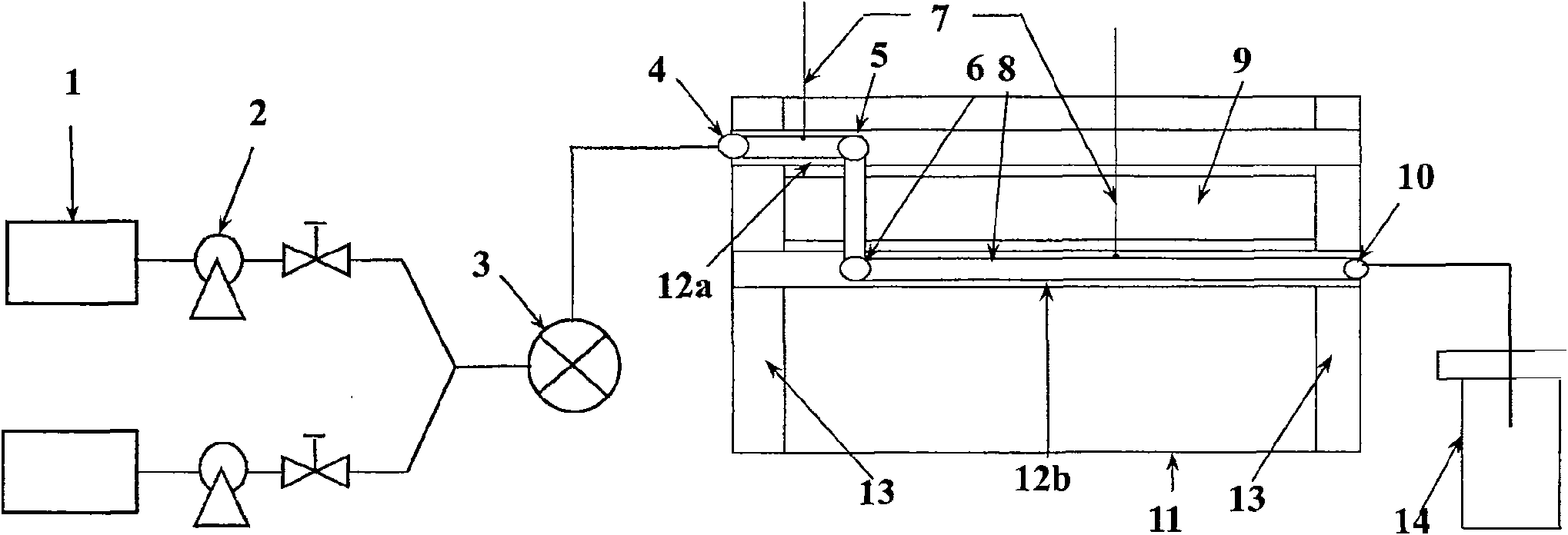

[0036](3) Plastic hoses are used to connect the syringe, the convective micro-mixer and the polytetrafluoroethylene micro-pipe to ensure strict sealing. A polytetrafluoroethylene capillary with an inner diameter of 0.3 mm was used as the reaction microchannel. Using a tube-type electric furnace as a heat source, fix a stainless steel tube (inner diameter 1mm) along the axis of the tube-type furnace at a position close to the heating resistance wire in the tube-type furnace, and place another stainless steel tube of the same specification parallel to it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com