Production of zinc sulfide electroluminescent fluorescent powder

A technology of phosphor and zinc sulfide, applied in the field of preparation of zinc sulfide electro-phosphor powder, can solve the problems of unfavorable electro-fluorescence lifetime, brightness, harmfulness, etc., and achieve the effect of easy selection and low eutectic point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

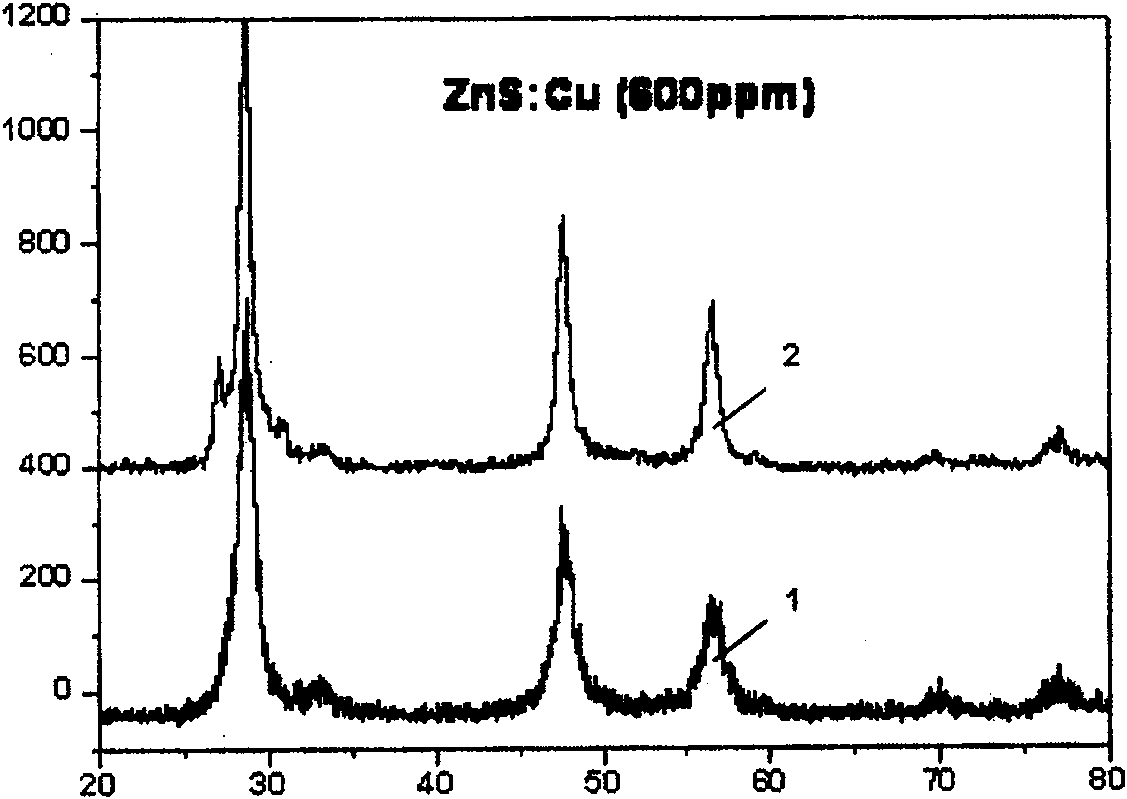

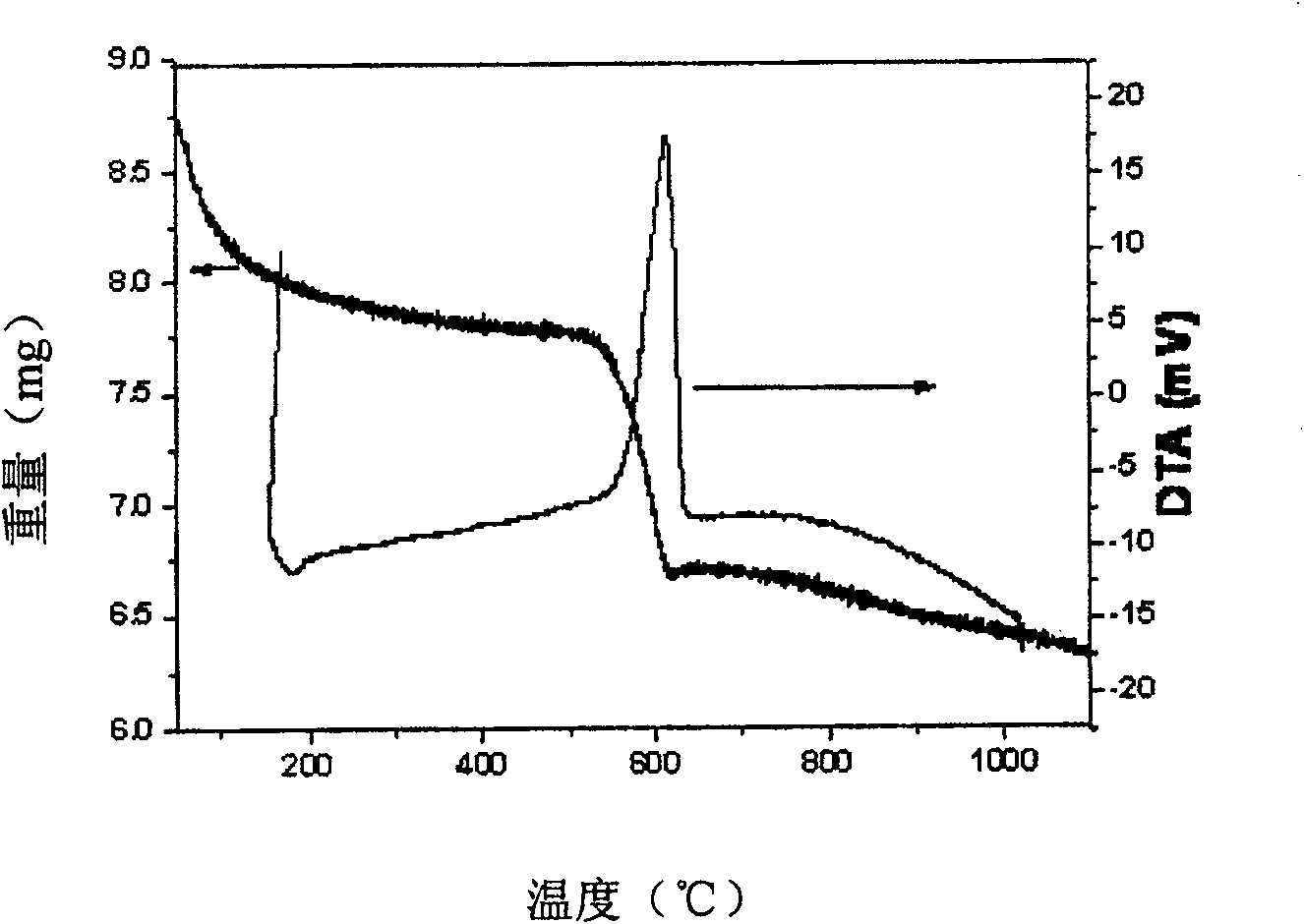

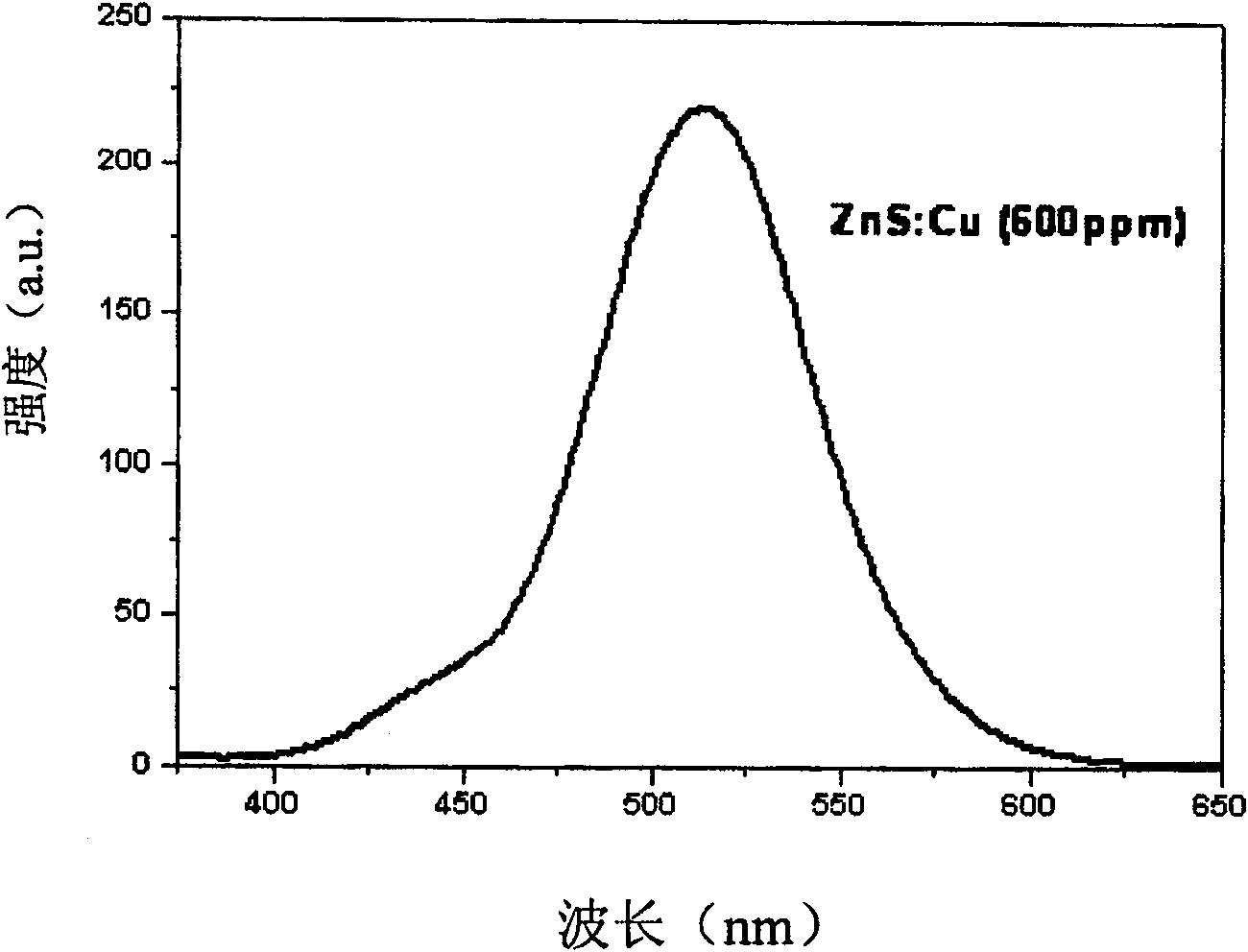

[0015] The raw materials ZnS, CuSO 4 (600ppm) and flux (8% by weight of ZnS, Na 2 S: MgCl 2 : BaCl 2 : S=1:2:1:1) were mixed by ball milling, placed in a capped quartz crucible, calcined in a furnace at 700°C for 3 hours, cooled to room temperature, then washed with deionized water and filtered to remove flux, and baked in an oven Dry and sieve to obtain a powder. The obtained powder was ball milled for 2 hours, annealed at 750°C for 2 hours, cooled in air, washed with dilute hydrochloric acid, deionized water, sodium cyanide and deionized water, and finally filtered, dried and sieved to obtain the finished product green Phosphor. The test results are shown in Table 1.

Embodiment 2

[0017] The raw materials ZnS, CuSO 4 (600ppm) and flux (8% by weight of ZnS, Na 2 S: MgCl 2 : BaCl 2 : S=1:2:2:1) were mixed by ball milling, placed in a covered quartz crucible, calcined in a furnace at 700°C for 5 hours, cooled to room temperature, then washed with deionized water and filtered to remove the flux, and dried in an oven , and sieve to obtain powder. The obtained powder was ball milled for 2 hours, annealed at 750°C for 2 hours, cooled in air, washed with dilute hydrochloric acid, deionized water, sodium cyanide and deionized water, and finally filtered, dried and sieved to obtain the finished product green Phosphor. The test results are shown in Table 1.

Embodiment 3

[0019] The raw materials ZnS, CuSO 4 (600ppm) and flux (8% by weight of ZnS, Na 2 S: MgCl 2 : BaCl 2 : S=1:2:2:1) were mixed by ball milling, placed in a covered quartz crucible, calcined in a furnace at 800°C for 3 hours, then cooled to room temperature, then washed with deionized water and filtered to remove the flux, and placed in an oven Dry and sieve to obtain powder. The obtained powder was ball milled for 2 hours, annealed at 750°C for 2 hours, cooled in air, washed with dilute hydrochloric acid, deionized water, sodium cyanide and deionized water, and finally filtered, dried and sieved to obtain the finished product green Phosphor. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com