Method for producing interpose porus titanium dioxide photocatalyst by hydro-thermal method in weak acid condition

A mesoporous titanium dioxide and photocatalyst technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc. To reduce the types and dosages, the reaction conditions are easy to control, and the hydrolysis speed is slow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

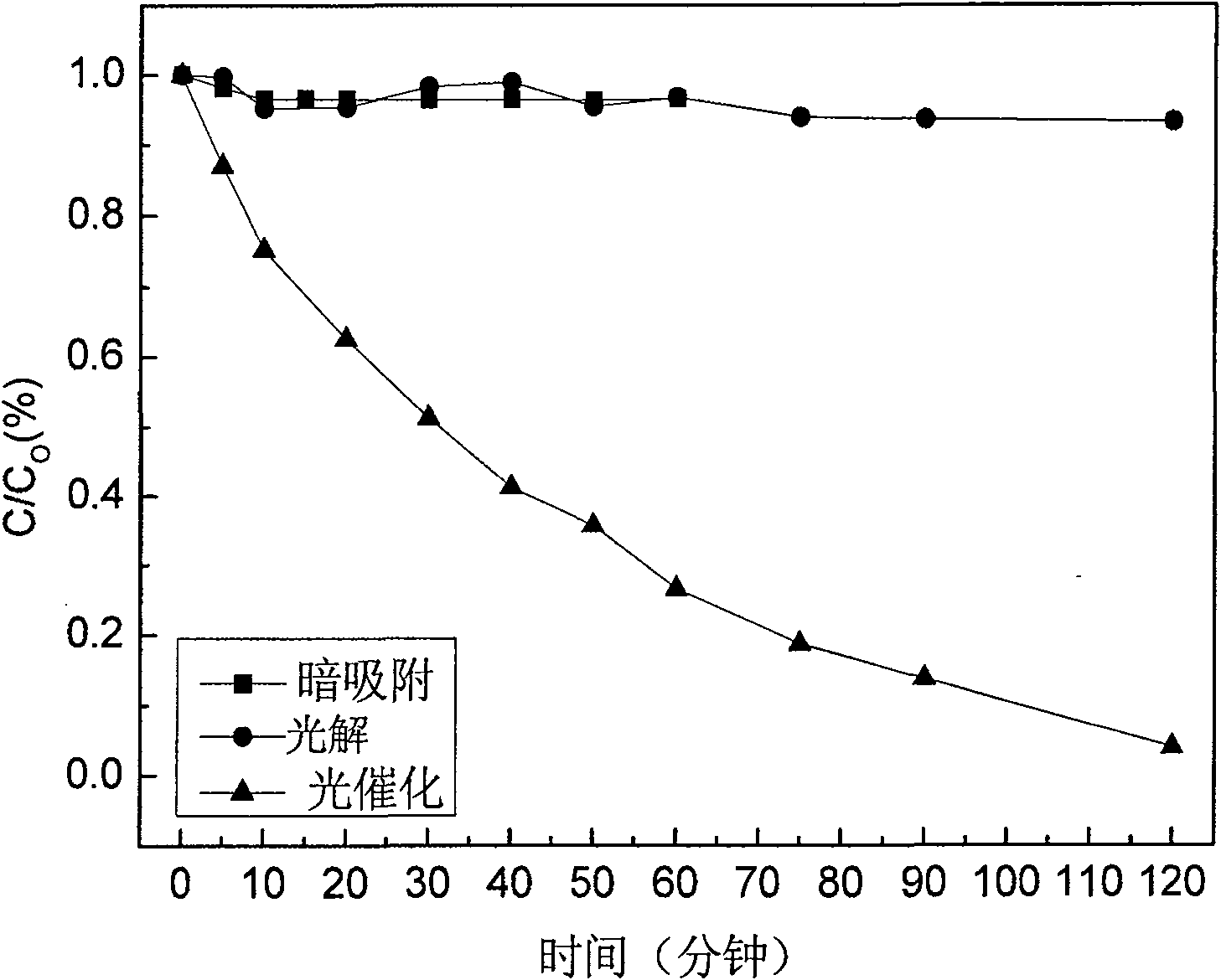

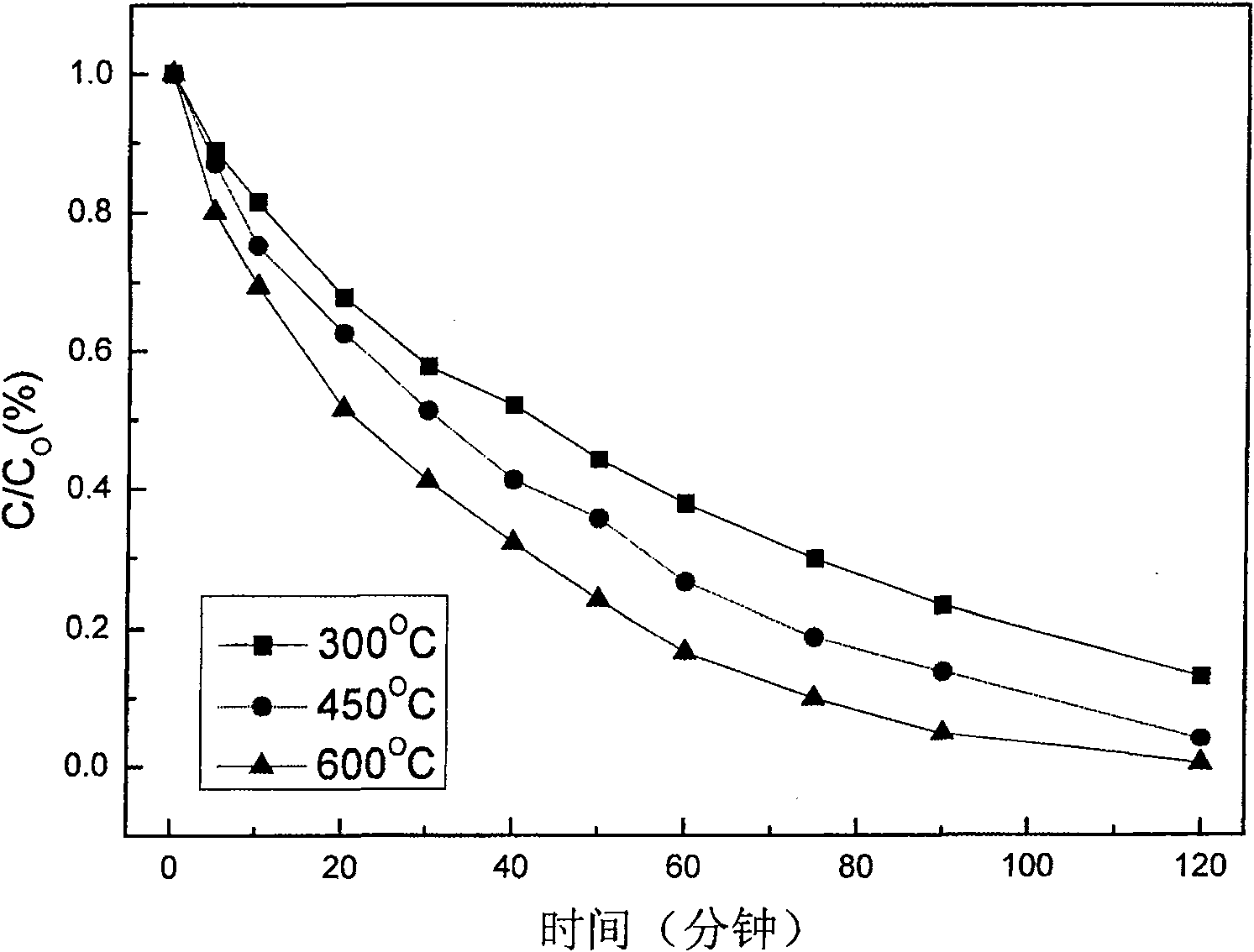

Embodiment 1

[0019] (1) Take 20 g of n-butyl titanate and add it dropwise into 120 mL of vigorously stirred acetic acid solution, the volume percentage of the acetic acid solution is 20%, and continue stirring for 4 hours to obtain an acetic acid solution of n-butyl titanate. Dissolve 1.5g of P123 in 10mL of absolute ethanol and stir until it is completely dissolved to obtain an ethanol solution of the non-ionic template agent. Then, the ethanol solution dissolved in P123 was added dropwise to the acetic acid solution of n-butyl titanate under vigorous stirring, and after the dropwise addition was completed, the stirring was continued for 24 hours to obtain a titanium sol.

[0020] (2) Transfer the stirred titanium sol to a polytetrafluoroethylene bottle, heat it with water at 120°C for 24 hours, and dry the product after hydroheating in an oven at 80°C to obtain a yellow gel-like solid, and then dry the dried solid Calcined at 300° C. for 4 hours in a muffle furnace to obtain a mesoporous...

Embodiment 2

[0022] (1) Take 20 g of n-butyl titanate and add it dropwise into 120 mL of vigorously stirred acetic acid solution, the volume percentage of the acetic acid solution is 20%, and continue stirring for 4 hours to obtain an acetic acid solution of n-butyl titanate. Dissolve 1.5g of P123 in 10mL of absolute ethanol and stir until it is completely dissolved to obtain an ethanol solution of the non-ionic template agent. Then, the ethanol solution dissolved in P123 was added dropwise to the acetic acid solution of n-butyl titanate under vigorous stirring, and after the dropwise addition was completed, the stirring was continued for 24 hours to obtain a titanium sol.

[0023] (2) Transfer the stirred titanium sol to a polytetrafluoroethylene bottle, heat it with water at 120°C for 24 hours, and dry the product after hydroheating in an oven at 80°C to obtain a yellow gel-like solid, and then dry the dried solid Calcined at 450° C. for 4 hours in a muffle furnace to obtain a mesoporous...

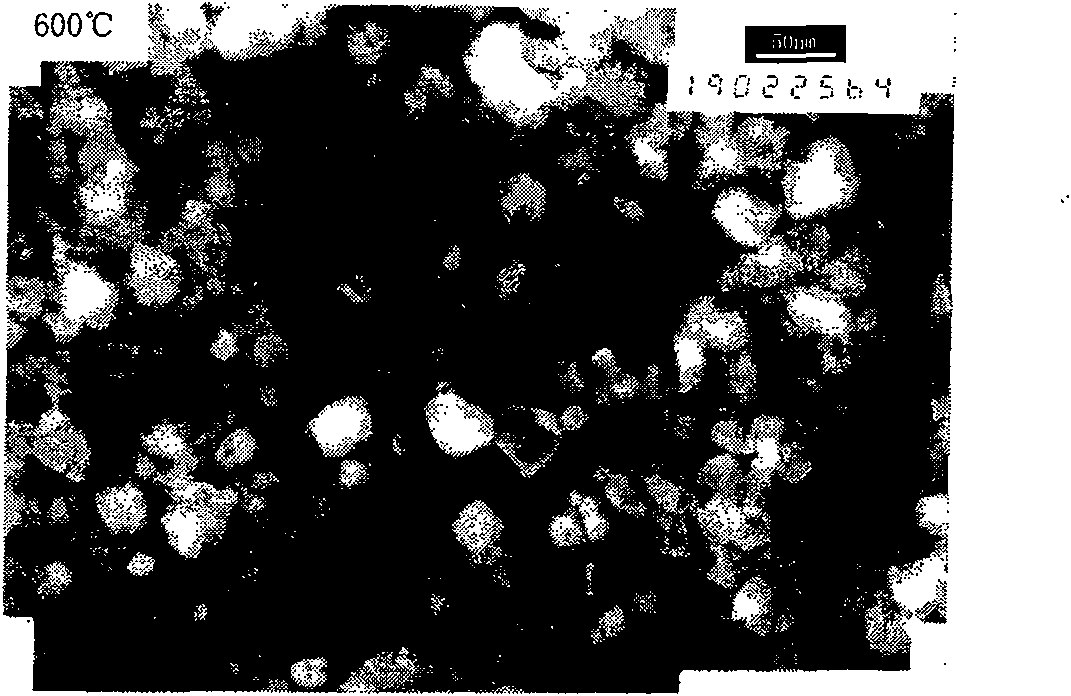

Embodiment 3

[0025] Preparation of mesoporous titania with P123 as template:

[0026] (1) Take 20 g of n-butyl titanate and add it dropwise into 120 mL of vigorously stirred acetic acid solution, the volume percentage of the acetic acid solution is 20%, and continue stirring for 4 hours to obtain an acetic acid solution of n-butyl titanate. Dissolve 1.5g of P123 in 10mL of absolute ethanol and stir until it is completely dissolved to obtain an ethanol solution of the non-ionic template agent. Then, the ethanol solution dissolved in P123 was added dropwise to the acetic acid solution of n-butyl titanate under vigorous stirring, and after the dropwise addition was completed, the stirring was continued for 24 hours to obtain a titanium sol.

[0027] (2) Transfer the stirred titanium sol to a polytetrafluoroethylene bottle, heat it with water at 120°C for 24 hours, and dry the product after hydroheating in an oven at 80°C to obtain a yellow gel-like solid, and then dry the dried solid Calcine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com