Speed control method for asynchronous motor

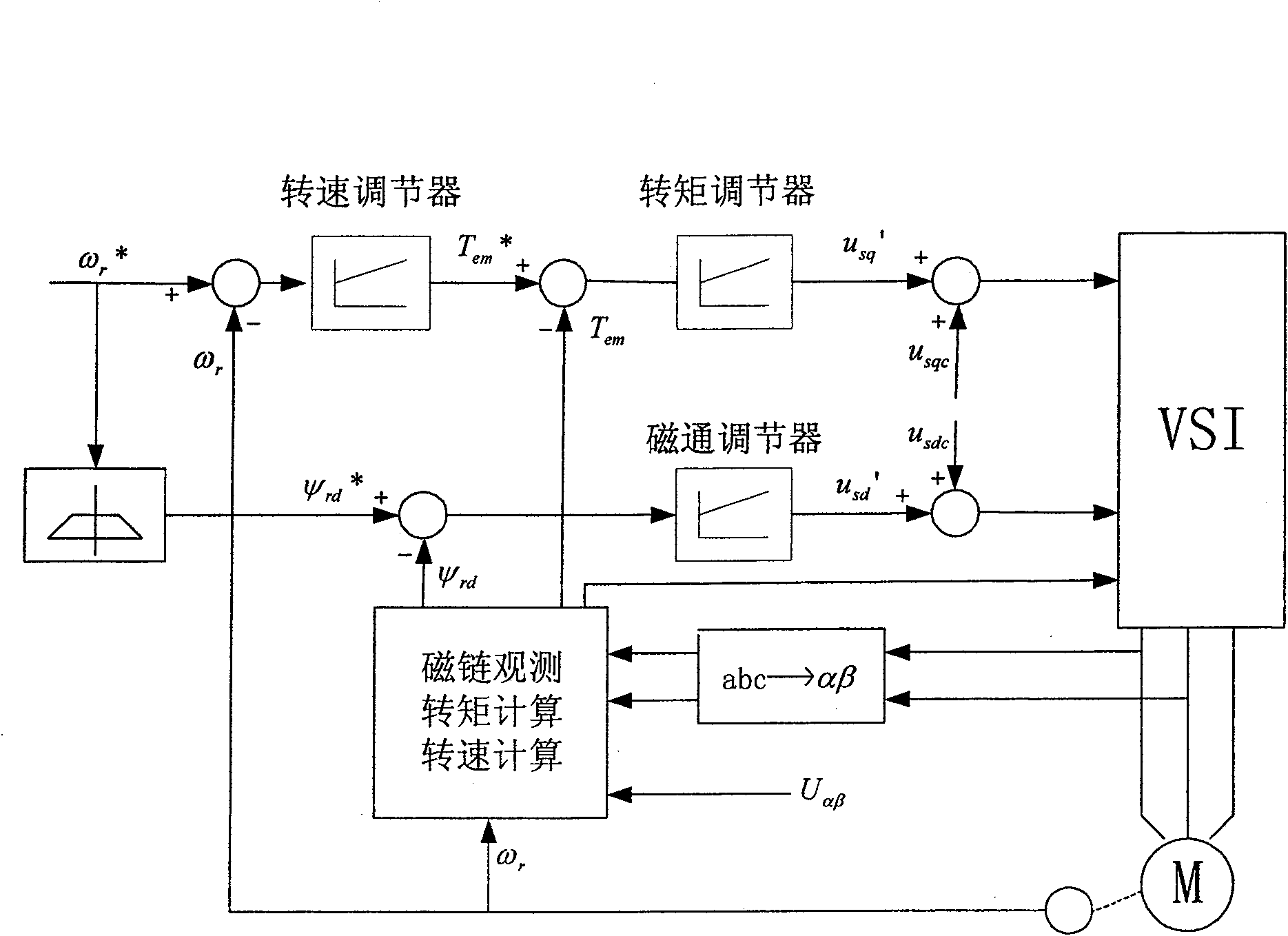

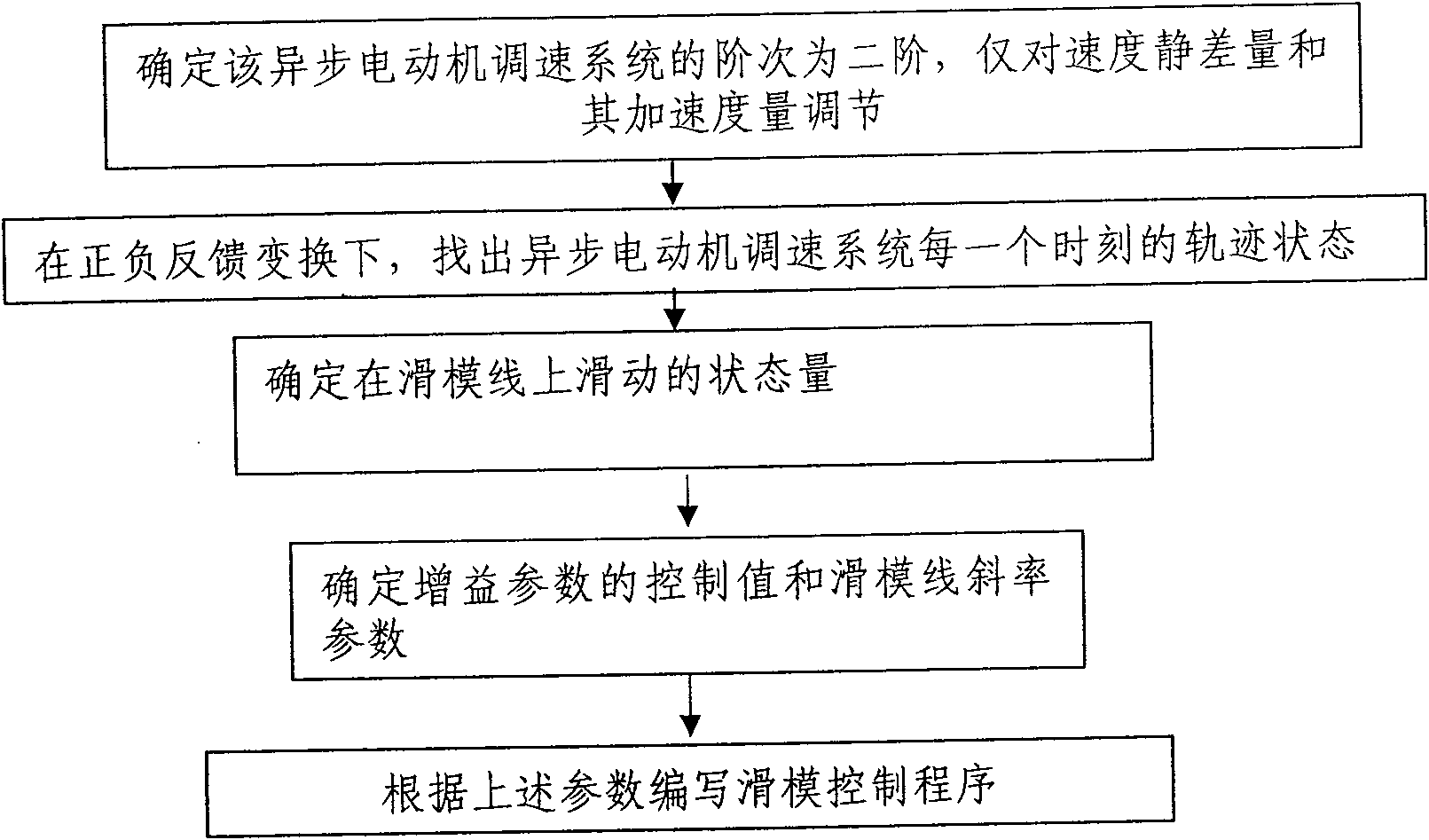

A technology of asynchronous motor and speed control, which is applied in the direction of motor generator control, electronic commutation motor control, control system, etc. It can solve the problems of poor system stability, poor shearing effect, long response time, etc., and achieve improved robustness , Reduce jitter, short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

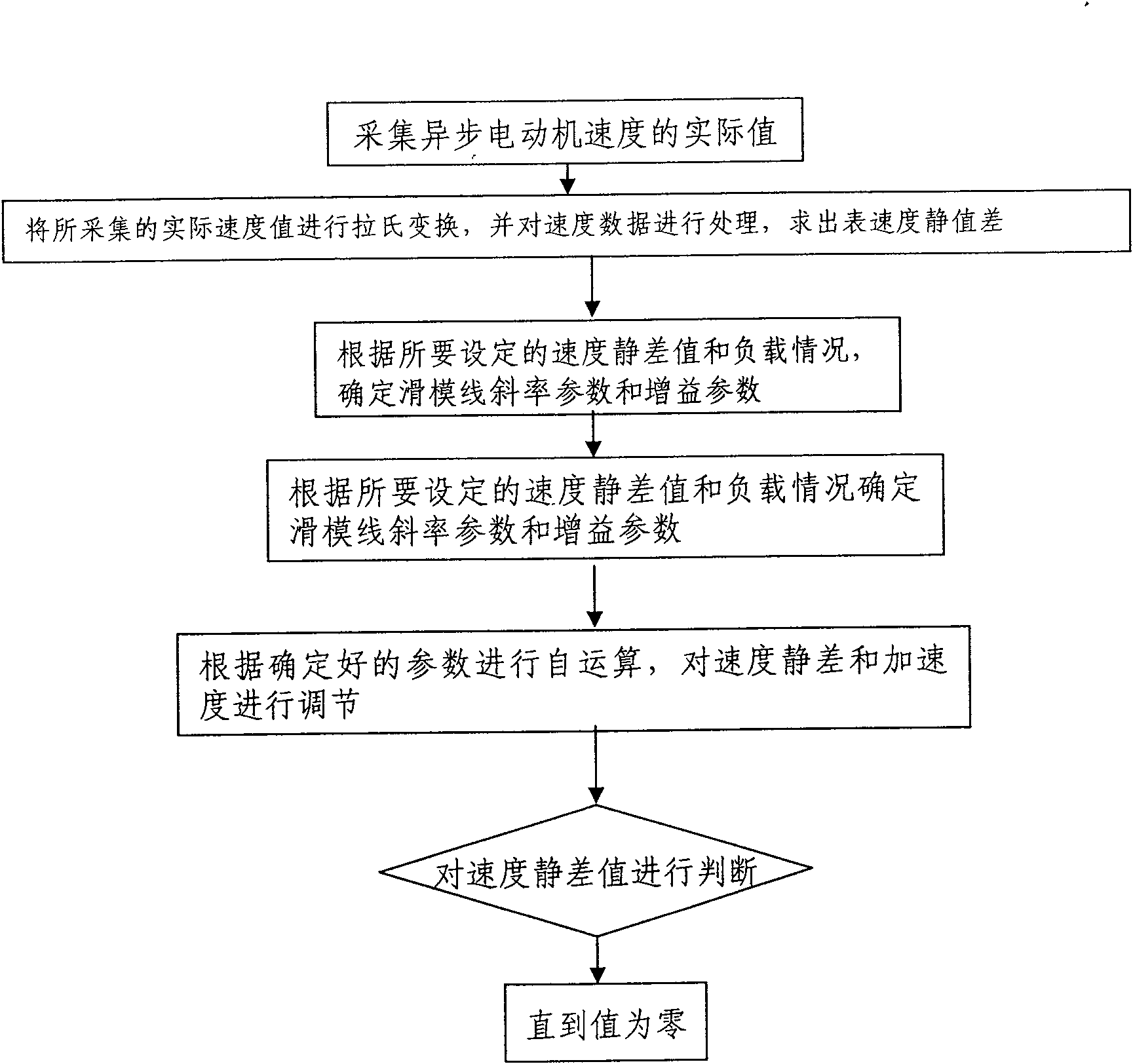

[0033] see figure 2 As shown, the speed control method of the asynchronous motor of the present invention includes the following steps:

[0034] a. Collect the actual speed value of the asynchronous motor. When collecting the actual speed value of the asynchronous motor, install a digital encoder at the end of the motor to detect the current value and speed value when the motor is stationary and running.

[0035] b. Perform Laplace transform on the collected actual speed value, and perform statistical processing on the collected speed data to obtain the static speed difference value, that is, the difference between the speed setting value and the actual speed value. When performing Laplace transformation on the actual speed value obtained, first establish the state equation of motor vector speed regulation, and then carry out Laplace transformation on its velocity and acceleration.

[0036] c. Determine the slope parameters and gain parameters of the sliding model line accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com