Imaging apparatus and method of manufacturing the same

A camera device and manufacturing method technology, applied in the direction of image communication, camera body, color TV parts, etc., can solve the problems of difficult device scale, miniaturization, and difficulty in manufacturing camera devices, and achieve the effect of reliable occlusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

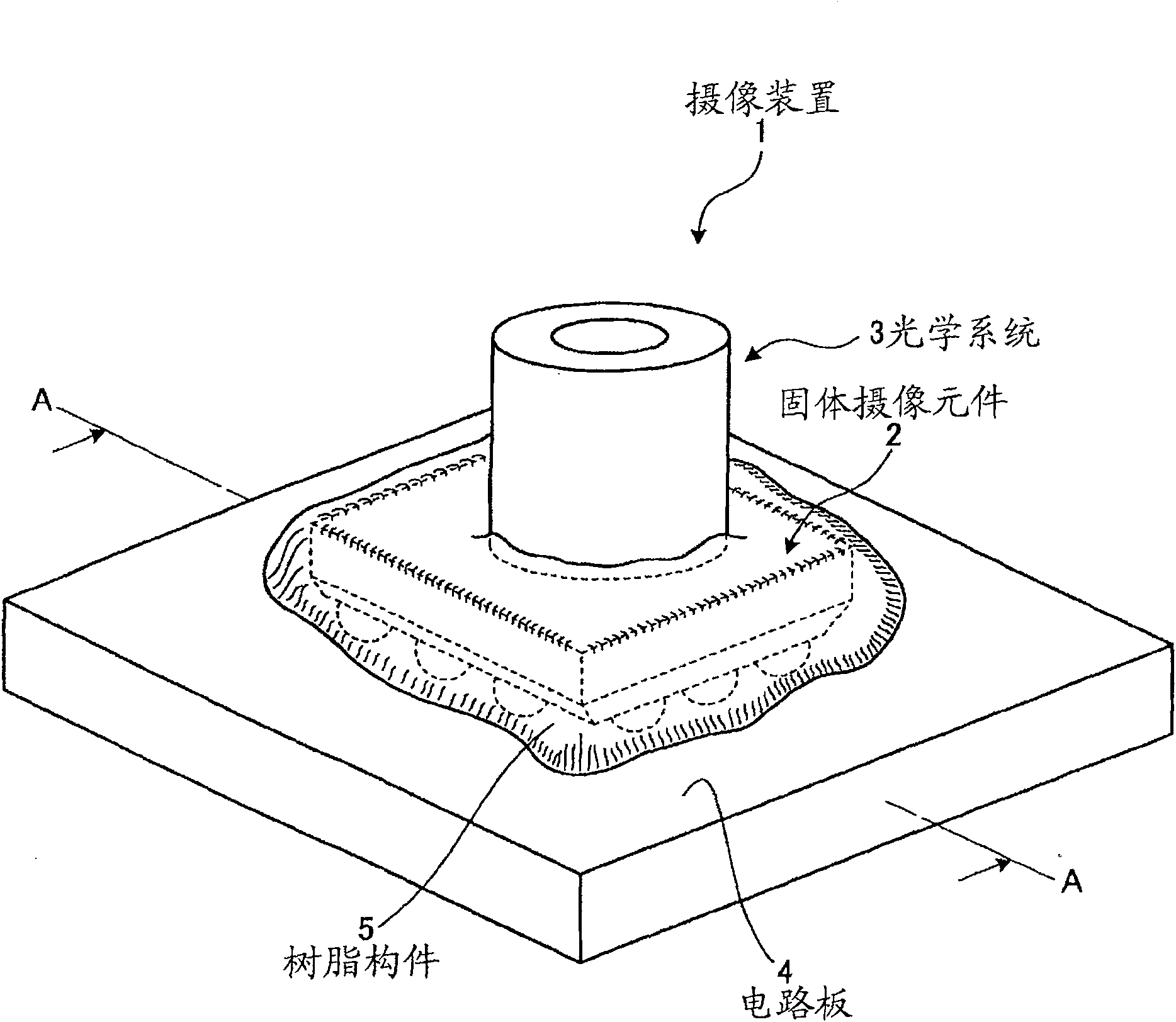

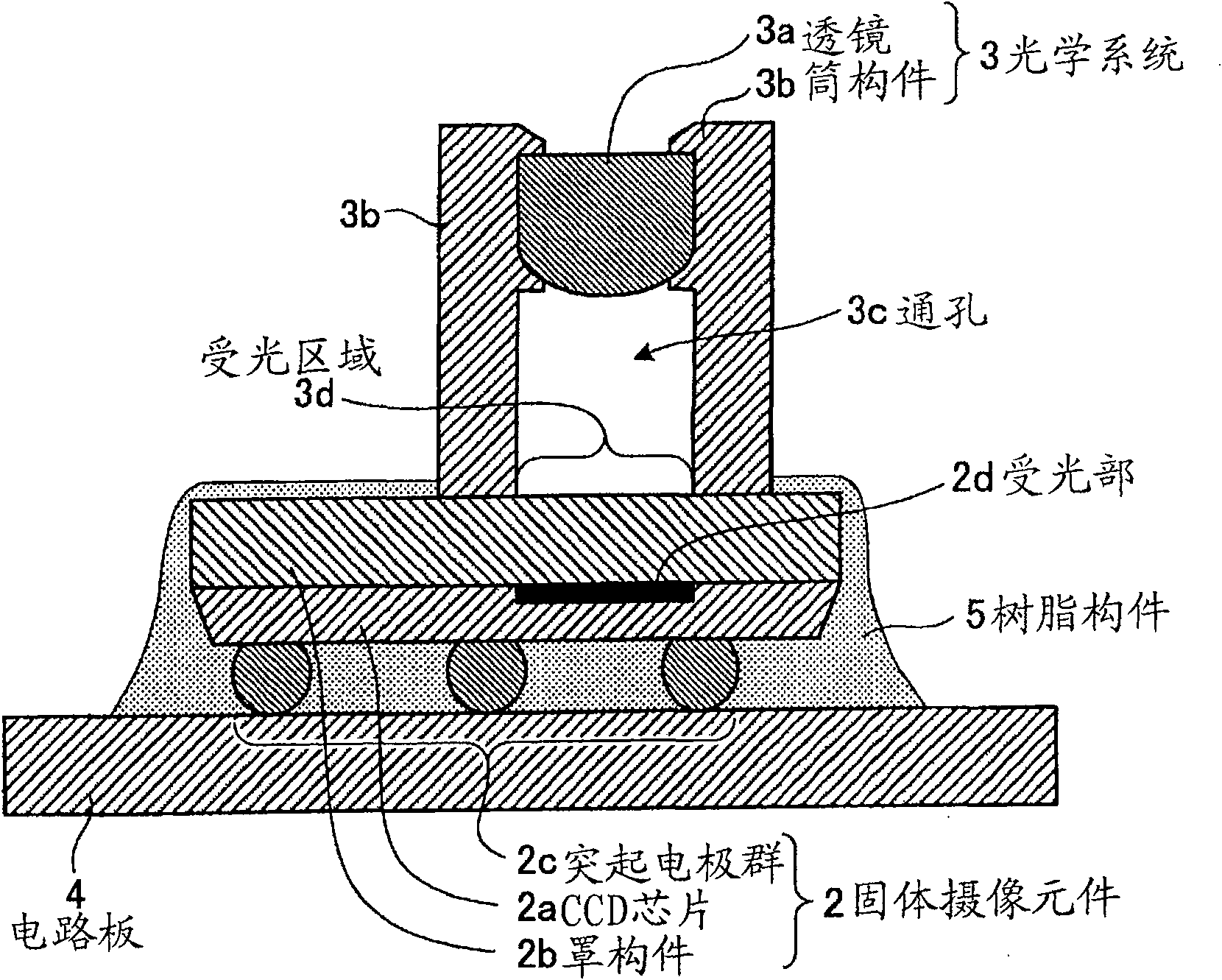

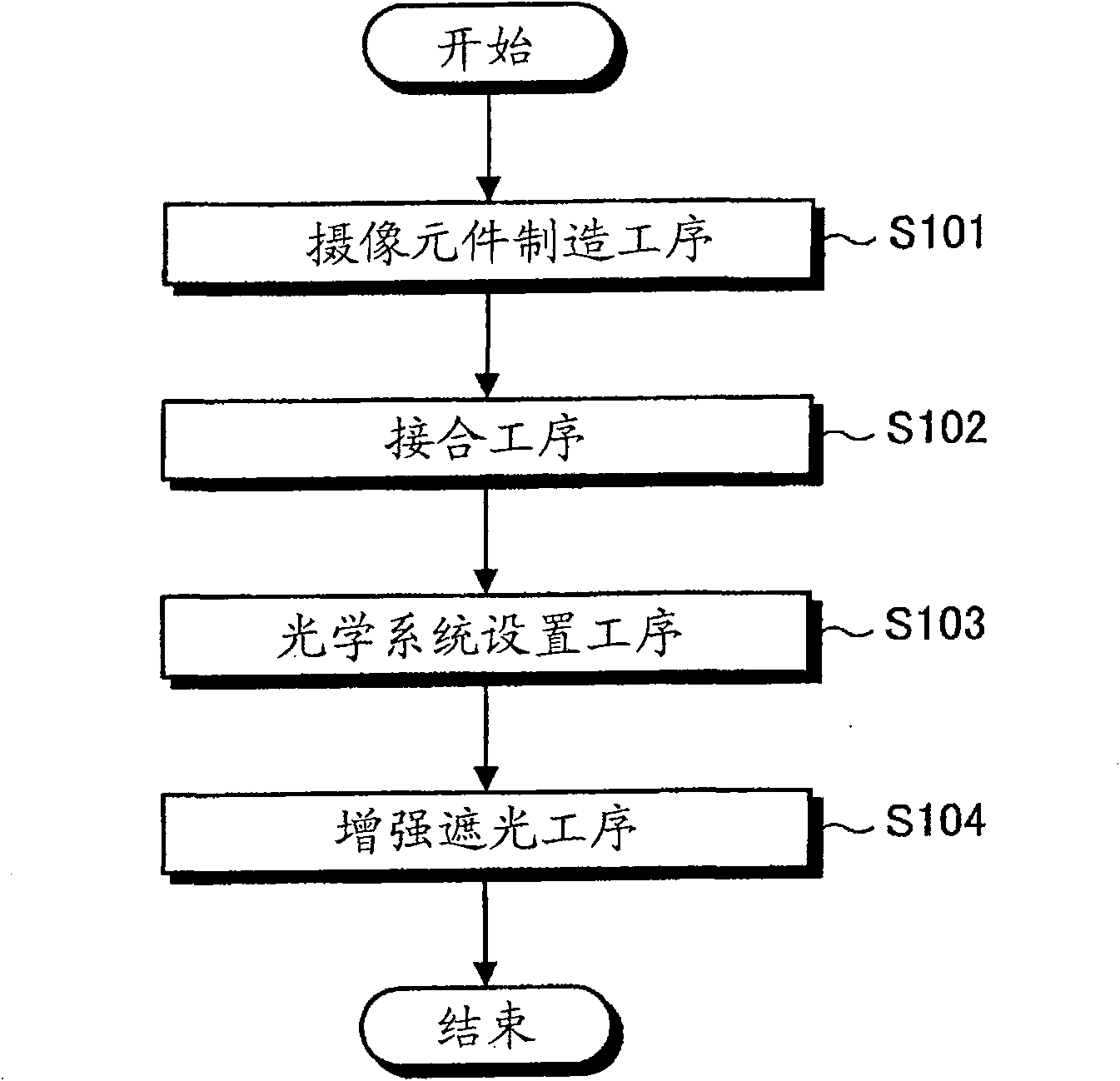

[0066] figure 1 It is a perspective view schematically showing a configuration example of the imaging device according to Embodiment 1 of the present invention. Such as figure 1 As shown, the imaging device 1 has: a solid-state imaging element 2, which receives light from an object and performs photoelectric conversion on the light to capture an image of the object; an optical system 3, which converges the light from the object On the light-receiving surface of the solid-state imaging element 2; the circuit board 4, which installs the solid-state imaging element 2; Areas other than those described above) are shaded.

[0067] Specifically, the package form of the solid-state imaging device 2 is a CSP type solid-state imaging device, the optical system 3 is provided on the upper surface, and the circuit board 4 is mounted on the lower surface side. Further, in the solid-state imaging device 2 mounted on the circuit board 4 in this way, the outer region of the installation r...

Embodiment approach 2

[0087] Next, Embodiment 2 of the present invention will be described. In the imaging device according to Embodiment 2, a positioning portion is formed on the cylindrical member of the optical system provided on the upper surface of the solid-state imaging element, and the positioning of the solid-state imaging element is determined by the positioning portion. Location.

[0088] Figure 4 It is a perspective view schematically showing a configuration example of the imaging device according to Embodiment 2 of the present invention. Figure 5 is illustrative Figure 4 B-B sectional schematic diagram of the side sectional structure of the imaging device shown. Such as Figure 4 , Figure 5 As shown, this imaging device 21 has an optical system 23 instead of the optical system 3 of the imaging device 1 of Embodiment 1 described above. The other configurations are the same as in Embodiment 1, and the same reference numerals are attached to the same configuration parts.

[0089...

Embodiment approach 3

[0095] Embodiment 3 of the present invention will be described below. This third embodiment realizes a capsule endoscope in which the imaging device 1 of the above-mentioned first embodiment is incorporated in a capsule-shaped housing.

[0096] Figure 9 It is a schematic cross-sectional view schematically illustrating a capsule endoscope incorporating the imaging device 1 according to Embodiment 1 of the present invention. Such as Figure 9 As shown, the capsule endoscope 201 has a capsule-shaped housing 202 formed in a substantially cylindrical shape, the housing 202 has an optical hemispherical cover 202a formed of a transparent optical member at one end, and an opaque hemispherical cover at the other end. 202b. In addition, the capsule endoscope 201 includes an imaging mechanism unit for imaging the inside of a body cavity to obtain image data, a wireless communication mechanism unit for transmitting various information including the image data, and a power supply unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com