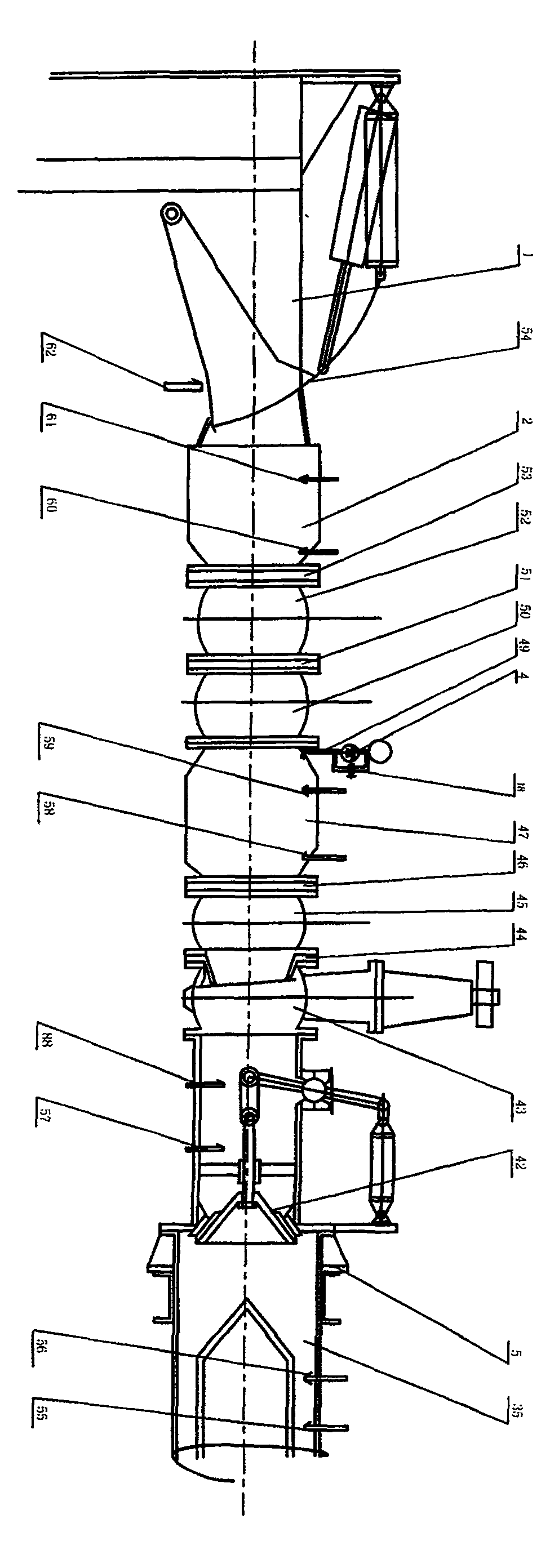

Gas continuous production vertical reducing furnace and magnesium refining method of the same

A reduction furnace and vertical technology, which are applied in the field of gas continuous production vertical reduction furnace and magnesium smelting, can solve the problems of restricting the production scale of Pidgeon method magnesium smelting, unsatisfactory economic benefits, and high labor intensity of workers, so as to reduce labor The effect of production intensity, saving resources and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for smelting magnesium using a gas-fired continuous production vertical reduction furnace. The gas-fired continuous production vertical reduction furnace adopts a continuous production method, and the upper loading, lower slag discharge, and middle magnesium discharge are carried out automatically and continuously without damaging the reduction reaction zone. Vacuum degree, the reduction reaction continues as usual. Follow these steps when loading for the first time:

[0052] (1) Preheating the reduction furnace by using the injector type fully premixed low nitrogen oxide burner 14:

[0053] There is a gap between the burner nozzle 75 and the fire channel 16, and between the fire channel 16 and the inner wall of the combustion chamber 8, and the gap is used to inject the gas and air to discharge the smoke from the annular high-temperature flue 9. The gas overflows at 27 places, sucks part of the high-temperature flue gas, and circulates up and down the fire ch...

Embodiment 2

[0076] Calcined ball is set as 600mm / h in descending speed in reduction reaction tube cavity 6, and the time that stays in reduction reaction tube cavity 6 is 6 hours, and the output of magnesium reaches 39.6 kilograms per hour. More than 2280 tons. Other steps are the same as in Embodiment 1.

Embodiment 3

[0078] Calcined ball is set as 650mm / h in descending speed in reduction reaction tube chamber 6, and the time that stays in reduction reaction tube chamber 6 is 5.5 hours, and the output of magnesium reaches 42.8 kilograms / hour. More than 2465 tons. Other steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com