Escalator middle part chain type classification drive device

A technology of graded drive and escalator, which is applied in the energy efficiency, transportation and packaging of escalators and escalators, can solve the problems of high processing precision, many materials required, and expensive manufacturing, and can meet the requirements of high processing precision. High, low material consumption, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

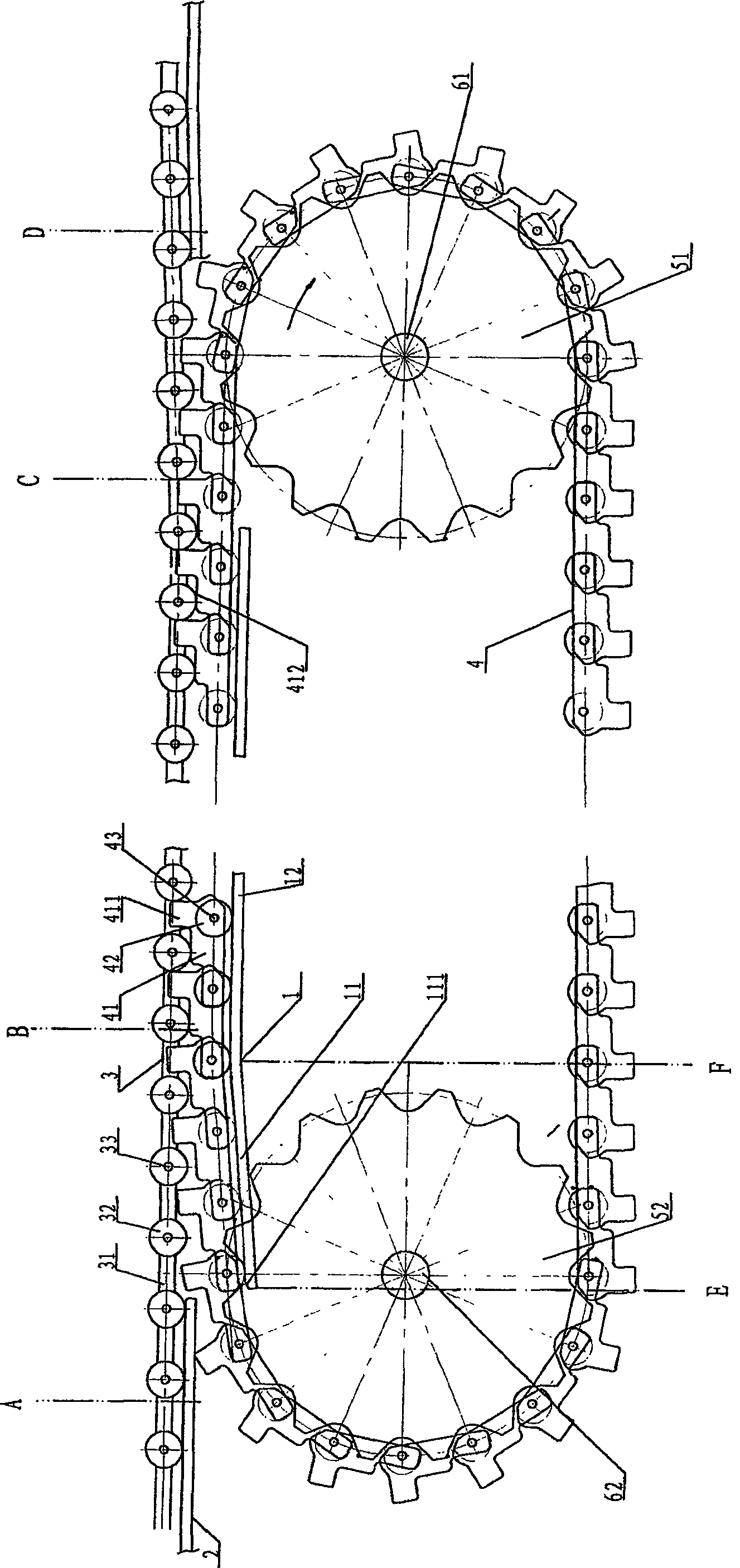

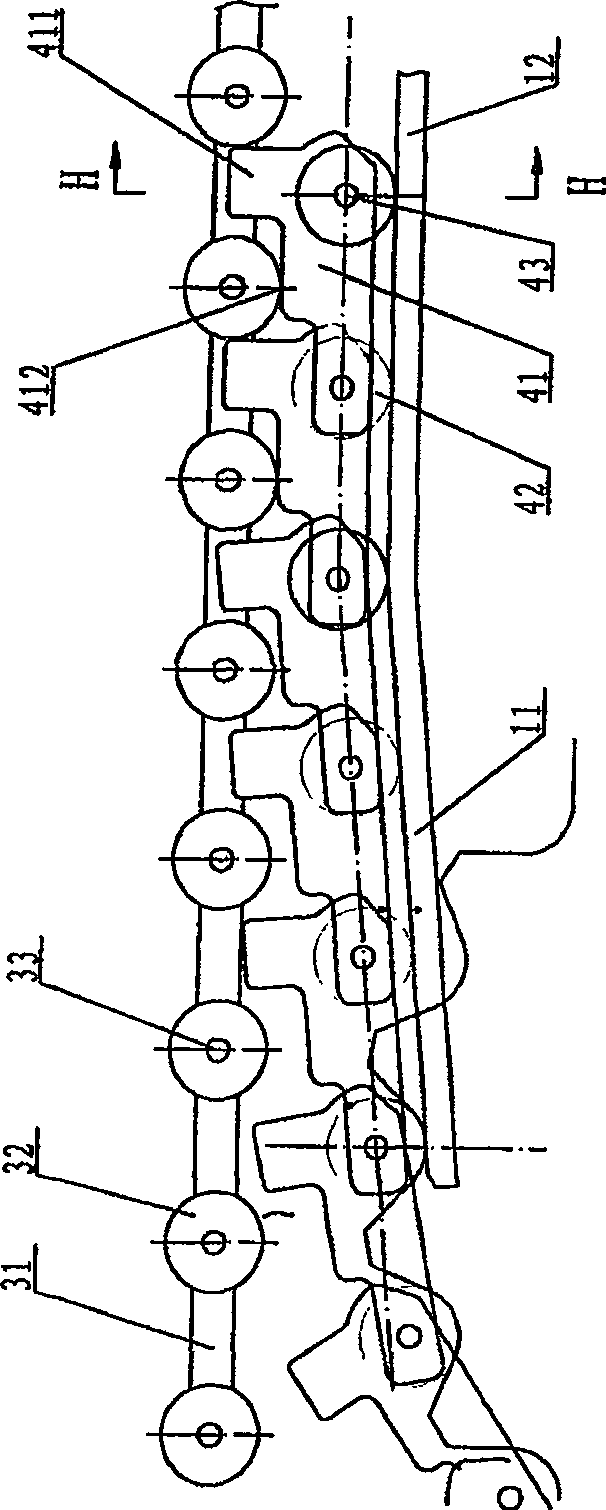

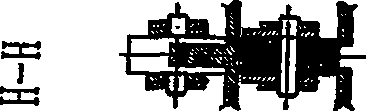

[0027] Such as Figure 1 to Figure 7 shown.

[0028] The central chain-type grading drive device of the escalator of the present invention comprises the original load step chain 3 of the escalator linked with the head chain drive device of the escalator and the step chain roller 32 in the load step chain 3 rolling on it Step main rail 2. The load step chain 3 is composed of multiple pairs of left and right matching step link blocks 31, a plurality of step chain rollers 32 and a plurality of step chain roller shafts 33, and the two ends of the step link blocks 31 are hinged on the step chain through the step chain roller shafts 33. on the roller 32. According to common sense, the multiple pairs of left and right matching step link blocks 31 are arranged in the axial direction as follows: two step link blocks 31 on the left and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com