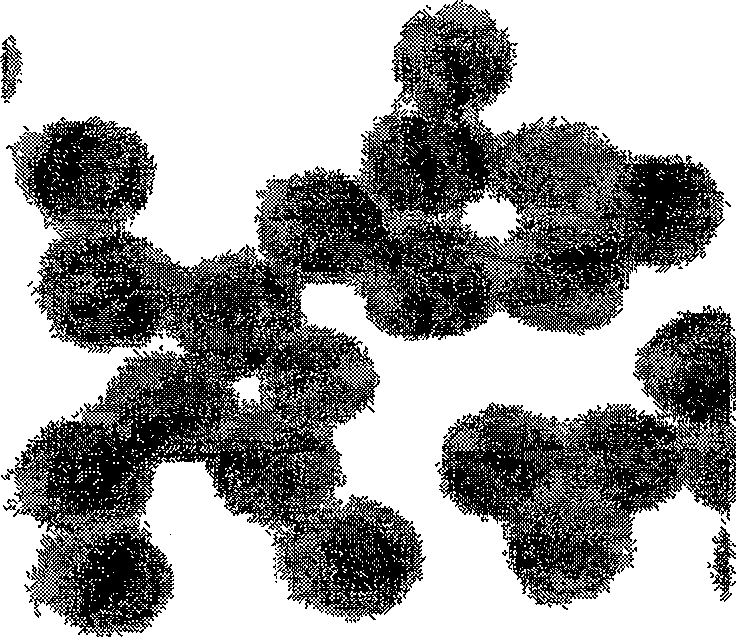

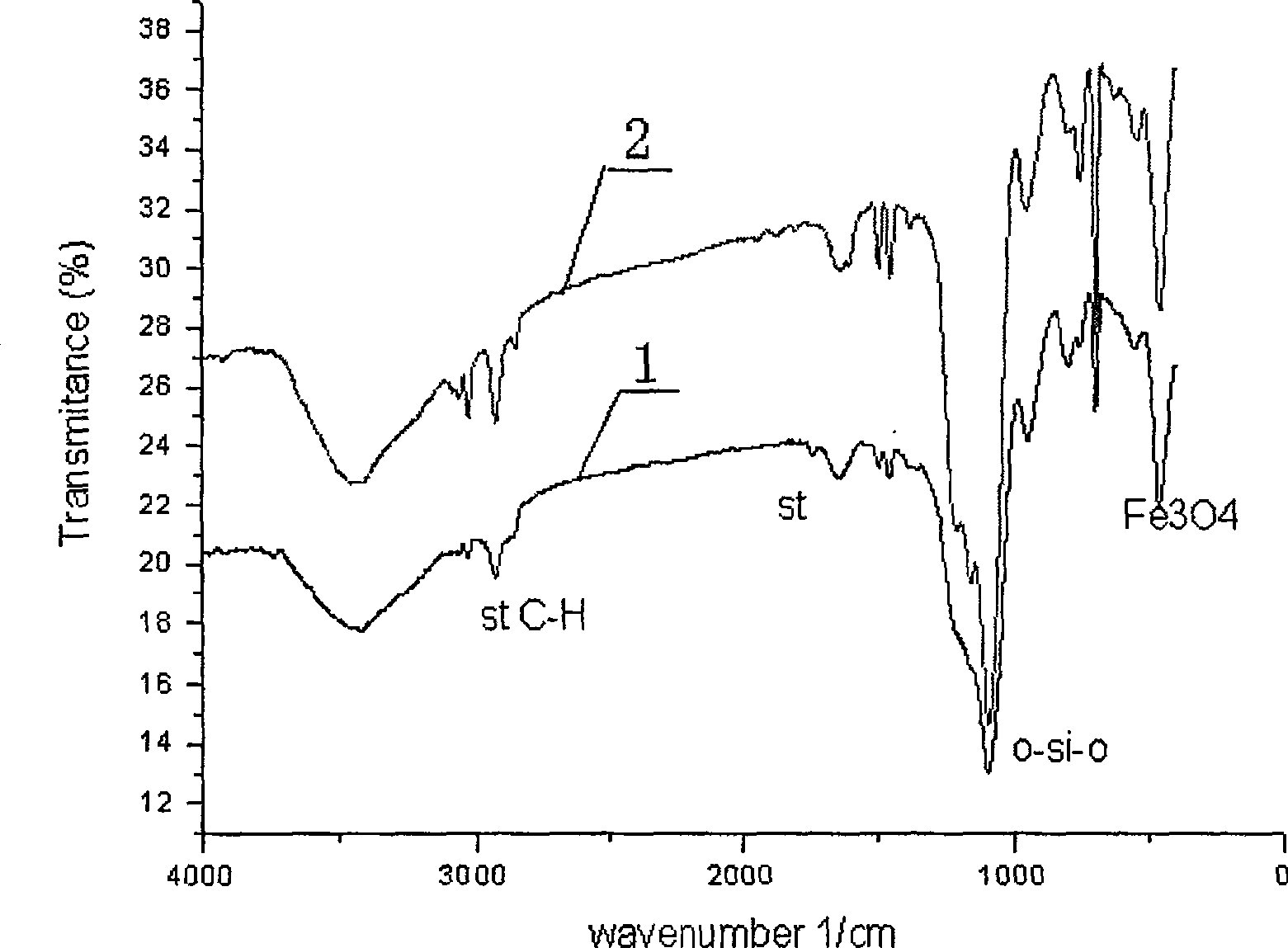

Superparamagnetism microsphere and method for manufacturing the same

A superparamagnetic and microsphere technology, which is applied in the direction of the magnetism of inorganic materials, can solve the problem of difficulty in controlling the content of microsphere magnetic ferric oxide particles, difficulty in synthesizing large-diameter magnetic polymer microspheres, and low yield of finished products. problems, to achieve the effect of easy organization of mass production, maintenance of chemical and physical stability, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 1. A method for preparing superparamagnetic microspheres, comprising the following steps:

[0031] A. Prepare metal ion solution;

[0032] B. Under vacuum or nitrogen protection and room temperature conditions, soak the dry porous or hollow microspheres in the metal ion solution for 18-24 hours, and then under vacuum or nitrogen protection, rotary evaporation at 20-60 degrees Celsius until the metal ions The water in the solution evaporates completely;

[0033] C. Add ammonia water or sodium hydroxide solution at 30-50 degrees Celsius to the evaporated porous or hollow microspheres, control the pH value to 9-11, raise the temperature to 60-90 degrees Celsius, stir for 10-50 minutes, and let stand to cool to room temperature , to separate porous or hollow magnetic microspheres from the solution under the action of a magnetic field;

[0034] D. Wash the porous or hollow magnetic microspheres with alcohol, add surfactant Tween-20 according to the ratio of porous or hollo...

Embodiment 1

[0044] Embodiment 1: Utilize solution polymerization to prepare the polymer dispersant of small molecular weight

[0045] The polymerization reaction is carried out in a three-neck flask equipped with a reflux condenser, stirring, and feeding device under nitrogen protection, and the reaction temperature is controlled at about 60 degrees Celsius. Add 150 milliliters of water, 5 milliliters of acrylic acid, and 1 gram of sodium chloride into a 250 milliliter there-necked flask and stir at a constant temperature for 10-15 minutes, then gradually add 5 milliliters of an initiator potassium persulfate aqueous solution with a mass fraction of 5%, and the polymerization reaction begins. React for 10-15 hours, cool, wash with alcohol water three times to remove sodium chloride, and obtain a stable polyacrylic acid latex solution. The above-mentioned typical dispersion polymerization method can also be used to prepare dispersant solutions such as polymethacrylic acid, polyacrylamide o...

Embodiment 2

[0046] Example 2: Preparation of monodisperse polymer microspheres by dispersion polymerization

[0047] Add double-distilled water, absolute ethanol, the polyacrylic acid latex solution and styrene in Example 1 respectively to a 250-milliliter three-necked flask equipped with a stirrer, a thermometer and a condenser, fill with nitrogen, and start stirring under nitrogen protection conditions ; Slowly heat up, after reaching 70-80 degrees Celsius, add azobisisobutyronitrile to start the reaction, after constant temperature reaction for 18-24 hours, cool and discharge. The polymer product is centrifuged, washed thoroughly with methanol, and dried to obtain polymer microspheres. Wherein the characteristic formula ratio is: the ratio of styrene accounts for 10.03% of the overall mass, absolute ethanol accounts for 68.56% of the overall mass, twice distilled water accounts for 20.4% of the overall mass, azobisisobutyronitrile accounts for 1.68% of the monomer, Polyacrylic acid ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com