Light conductive board and the backlight module using same

A technology of light guide plate and light source, applied in the direction of light guide, optics, optical components, etc., can solve the problems of uneven outgoing light and low utilization rate of light of light guide plate, so as to simplify the assembly process, improve the light intensity and luminous uniformity, save money cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

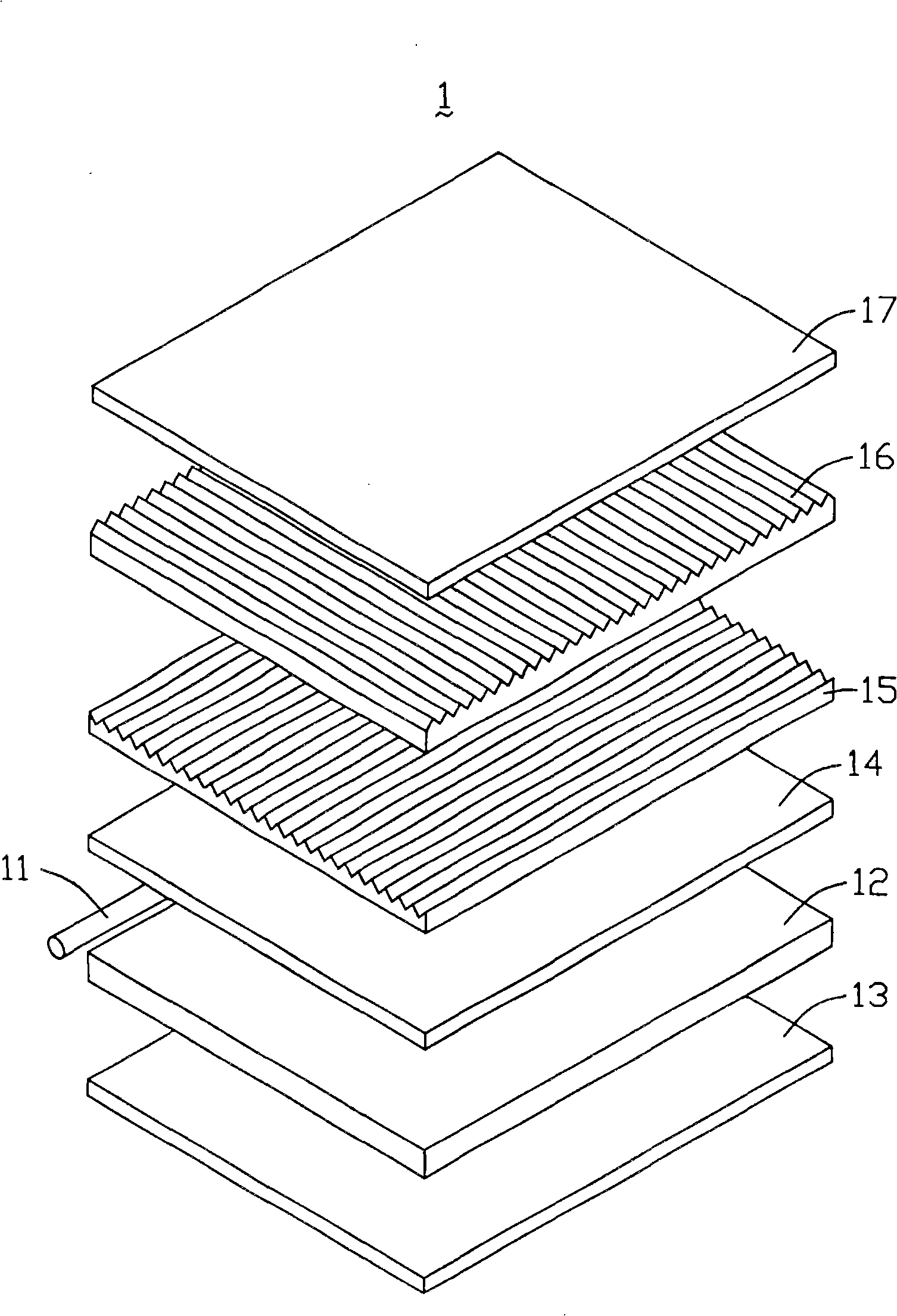

[0030] See Figure 6 , Is a schematic diagram of the three-dimensional structure of the backlight module disclosed in the first embodiment of the present invention. The backlight module 2 includes a light guide plate 20 and a light source 22.

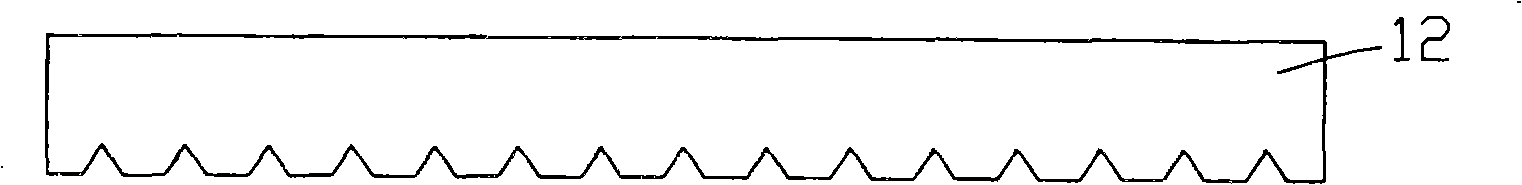

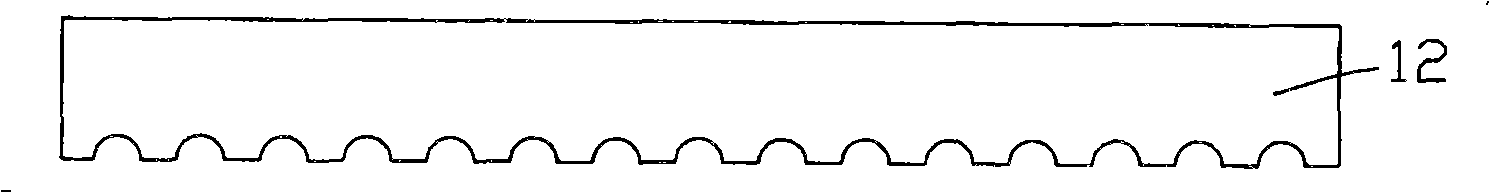

[0031] The light guide plate 20 is a transparent plate, which includes a bottom surface 201, a light-emitting surface 203 and a light-incident surface 205. The light incident surface 205 is a side surface of the light guide plate 20, and the bottom surface 201 and the light exit surface 203 are respectively a set of oppositely arranged lower and upper surfaces of the light guide plate 20. A plurality of V-shaped microstructures 2011 are provided on the bottom surface 201, and the plurality of V-shaped microstructures 2011 are a set of straight V-shaped grooves arranged in a direction parallel to the light incident surface 205. The light guide plate 20 is made of an optical plastic material, and the material can be Poly Methy Lmethacry Late ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com