Heat pipe

A heat pipe and heat transfer technology applied to heat pipes. It can solve the problems of small heat dissipation area in the condensation section, large temperature difference between the evaporation section and the condensation section, blockage or restriction of steam, etc., and achieve the effect of enhancing heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

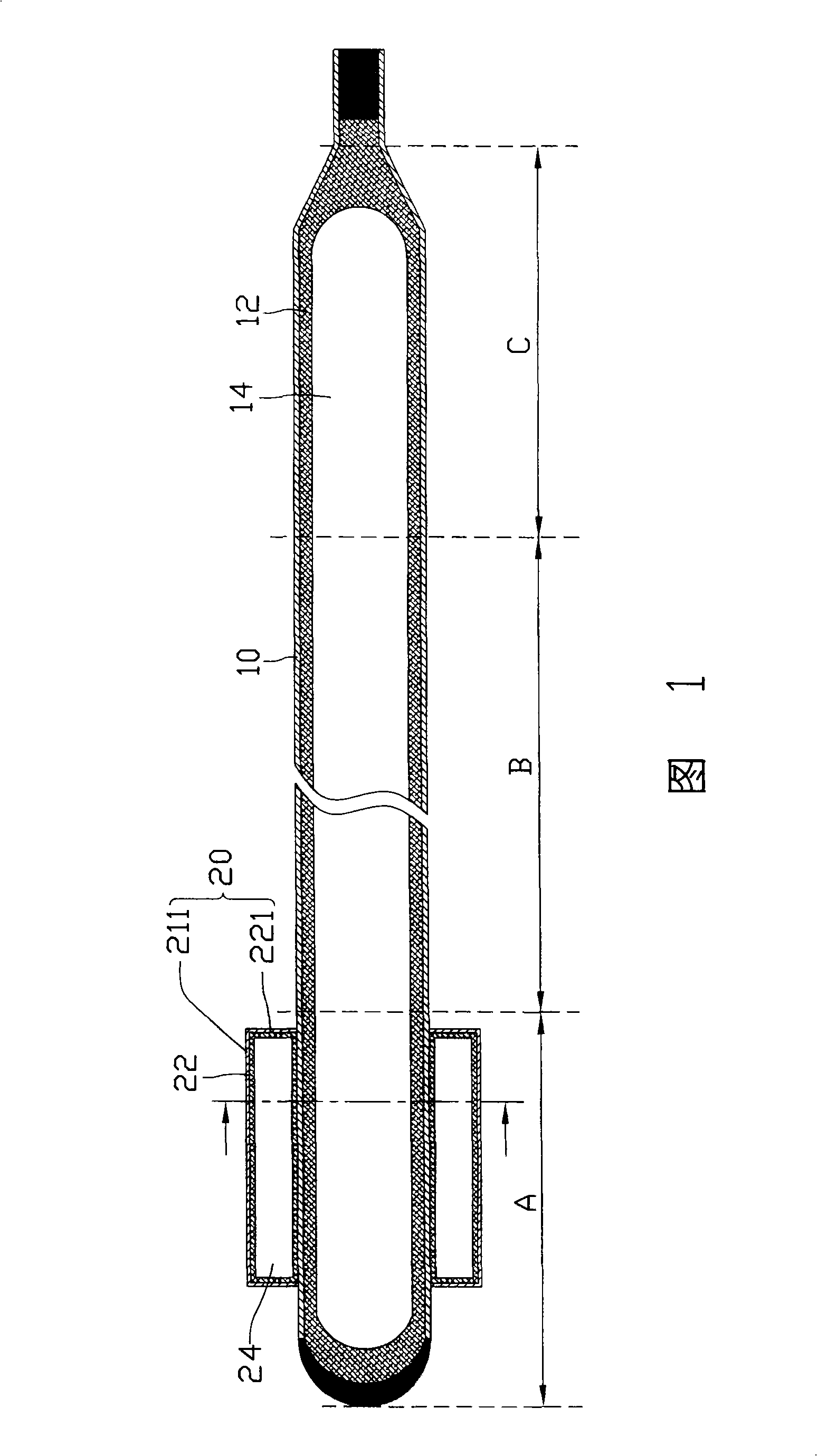

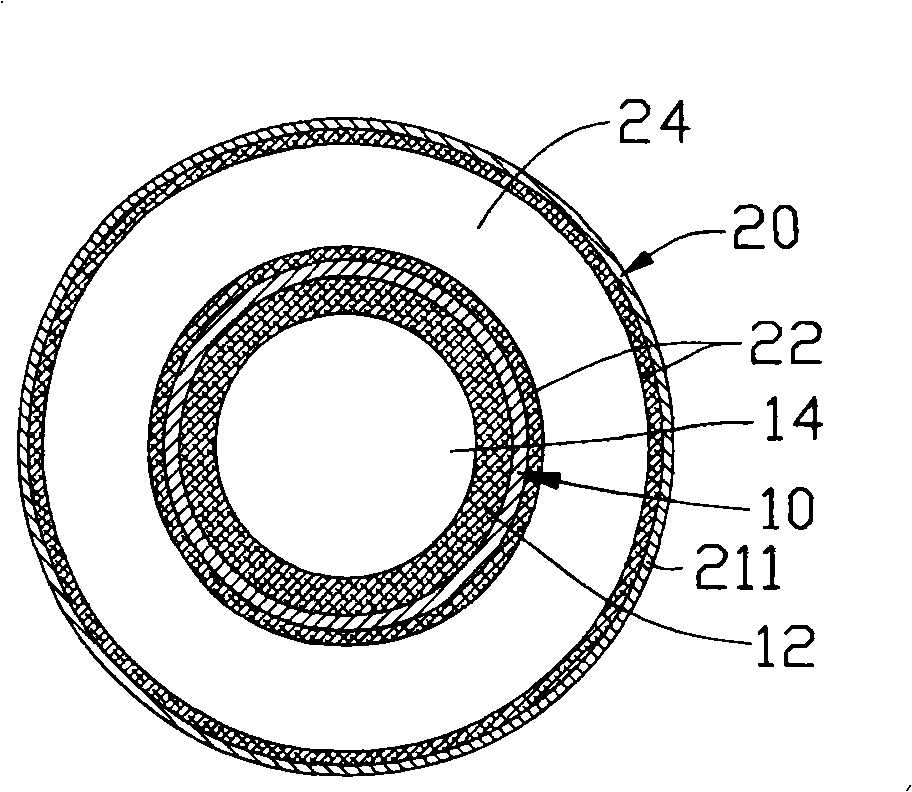

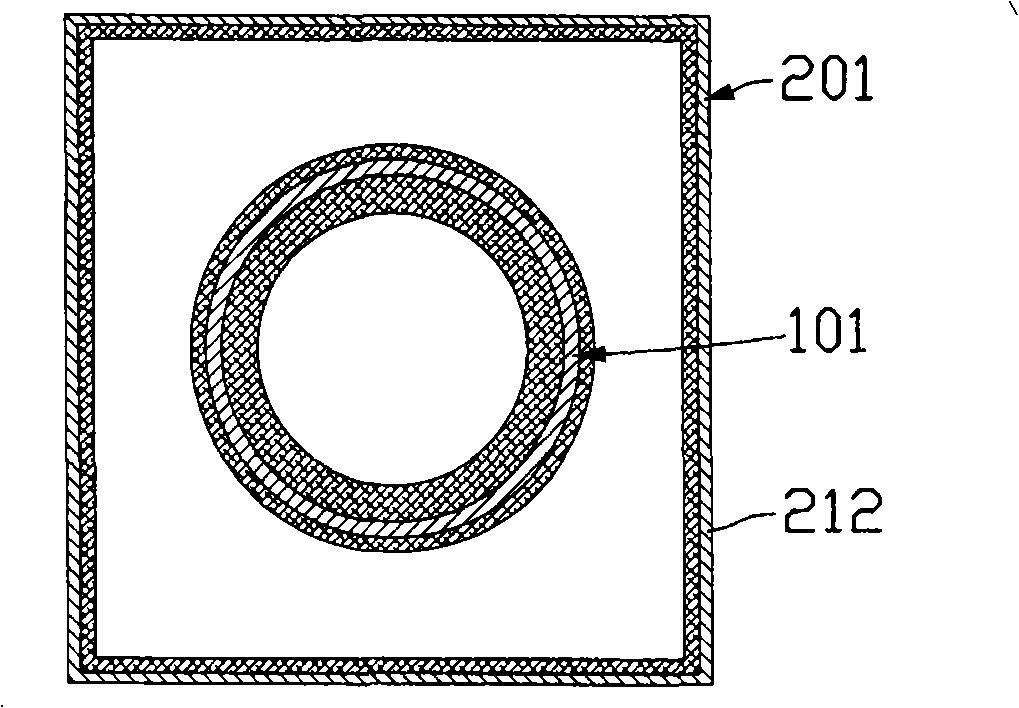

[0011] see figure 1 , is a longitudinal cross-sectional view of an embodiment of the heat pipe of the present invention; the shown heat pipe includes a sealed heat transfer cavity 10 formed by a metal shell, and the inner surface of the shell is provided with a capillary structure 12 for reflux of condensate, and The central space inside the capillary structure 12 is a steam channel 14, and an appropriate amount of working fluid is sealed inside the heat transfer cavity 10 and can be moderately pumped to a certain degree of vacuum; The use function of each section can be divided into evaporation section C, condensation section A and heat insulation section B located between them; the outer wall of the heat transfer chamber 10 corresponding to the condensation section A is sealed with a heat storage chamber 20 . Wherein, the heat transfer cavity 10 is a metal tube made of aluminum, copper or their alloys with better thermal conductivity, and the heat storage cavity 20 is made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com