Two-segment hydrocracking method

A hydrocracking and hydrofining technology, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, can solve the problems of increased investment and complex process flow, and achieve low total cost, simple process flow, and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

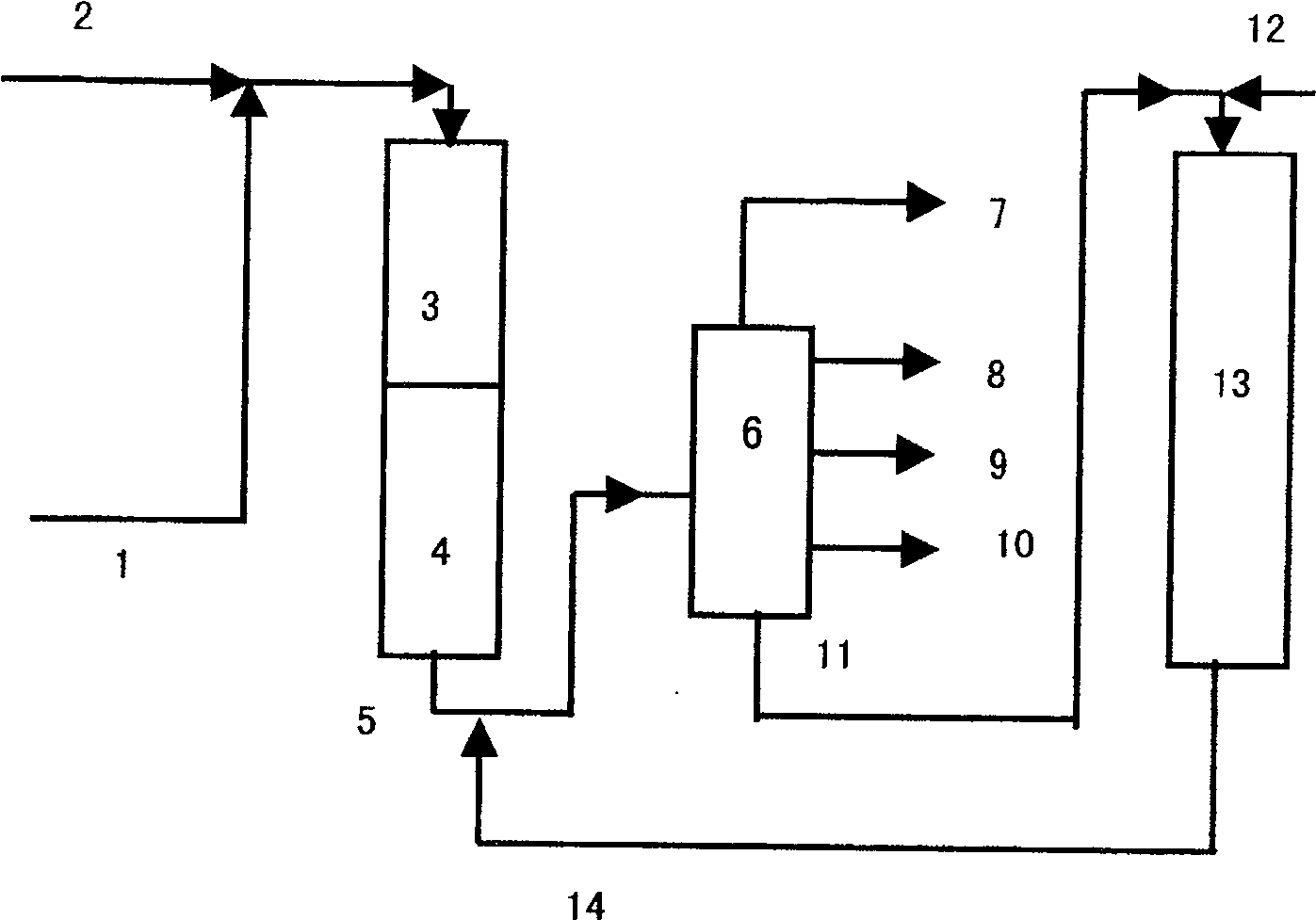

Method used

Image

Examples

Embodiment 1

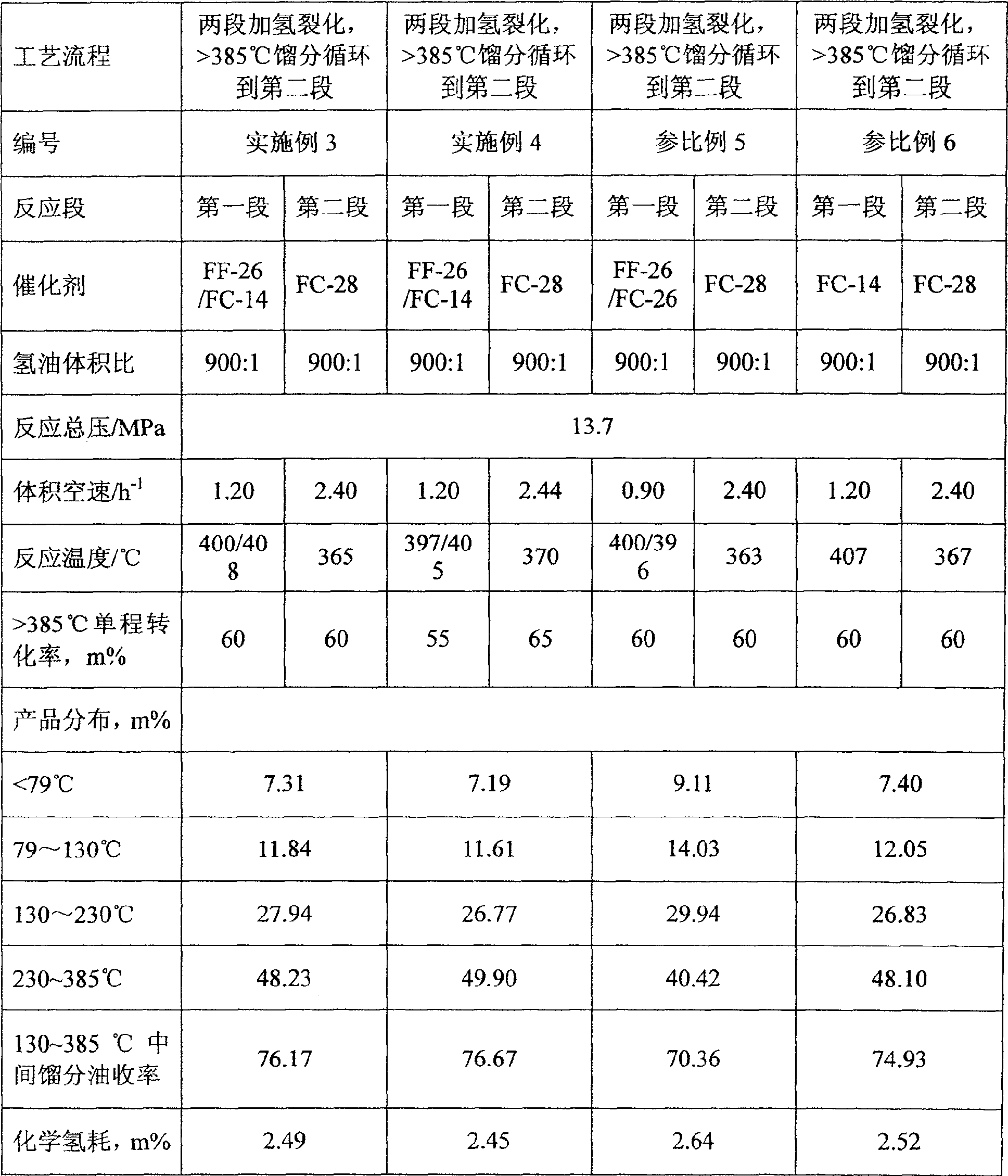

[0027] Example 1 is an example of a single-stage two-agent full-circulation process, which does not include the second-stage hydrocracking, and the tail oil is recycled back to the inlet of the first stage to illustrate the advancement of the single-stage two-agent hydrocracking process. The conditions and results are shown in Table 1 below.

[0028] Table 1 Example of a single-stage two-dose full cycle process

[0029] Example 1 Reference example 1 Raw oil properties VGO in the sand VGO in the sand Density / kg·m -3 924.9 924.9 Distillation range / ℃ 337~539 337~539 Sulfur content / m% 2.53 2.53 Nitrogen content / μg·g -1 766 766 Hydrocracking process conditions catalyst 3996 / ZHC-02 ZHC-02 Catalyst loading ratio by volume 40:60 / Pressure / MPa 15.7 15.7 temperature / ℃ 407 / 410 415 Volumetric space velocity / h -1 1.0 1.0 Hydrogen oil volume ratio 1240:1 1240:1 Conversion per pass...

Embodiment 2

[0031] Example 2 is an example of a single-stage two-agent single-pass process, which does not include the second-stage hydrocracking, and the tail oil does not circulate, which further illustrates the advancement of the single-stage two-agent hydrocracking process. Conditions and results are shown in Table 2 below.

[0032] Table 2 Example of single-pass flow process for raw oil

[0033] implementation plan Example 2 Reference example 2 Reference example 3 Reference example 4 Raw oil properties Iran VGO Iran VGO Iran VGO Iran VGO Density / kg·m -3 913.5 913.5 913.5 913.5 Distillation range / ℃ 285~537 285~537 285~537 285~537 Sulfur content / m% 1.74 1.74 1.74 1.74 Nitrogen content / μg·g -1 1514 1514 1514 1514 Hydrocracking process conditions catalyst FF-16 / FC-14 FC-14 FF-16 / 3976 FF-16 / 3976 Catalyst loading volume ratio 42:58 / 1:1 42:58 Pressure / MPa 15.7 15.7 15.7 15.7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com