Proton exchange film fuel cell

A proton exchange membrane and fuel cell technology, applied in fuel cells, solid electrolyte fuel cells, fuel cell groups, etc., can solve problems such as insufficient gas supply, scrapped fuel cells, complicated connection and management, etc., and achieve the goal of water blockage in the flow field Chance reduction, weight and volume reduction, gas distribution equal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

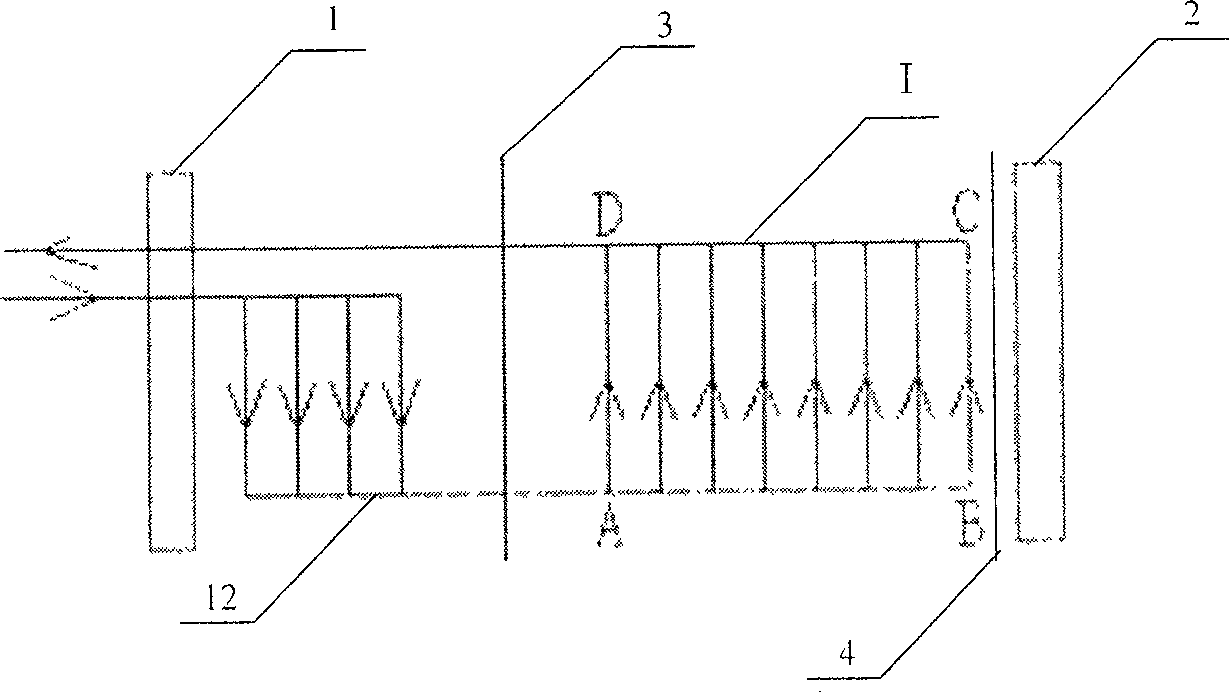

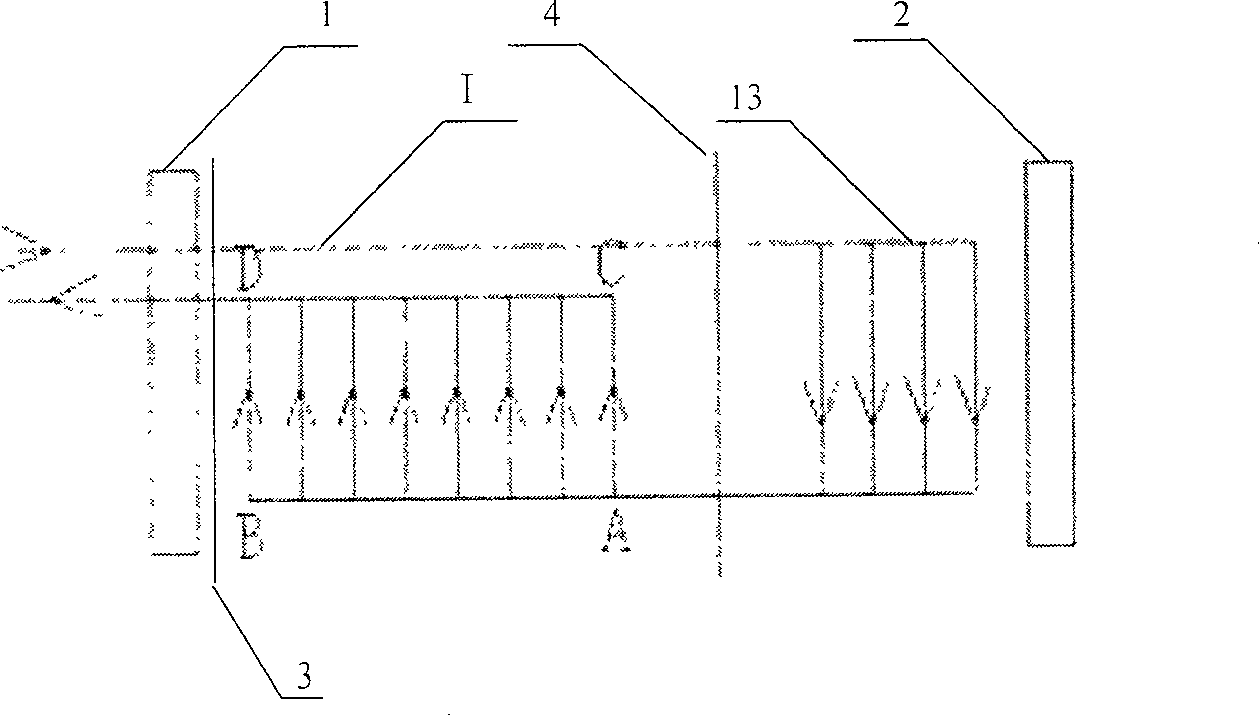

Embodiment 1

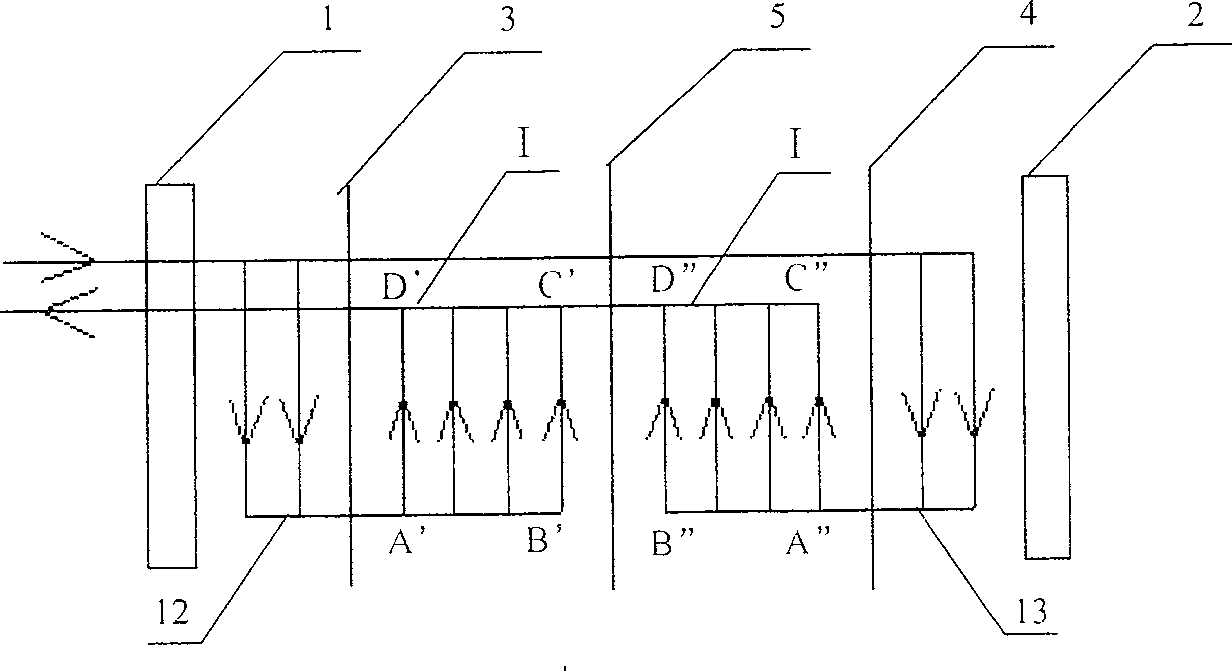

[0050] like figure 1 , 2 As shown, the basic unit group forms the active area I, and the AB section and the CD section are respectively the gas inlet shaft channel and the gas outlet shaft channel in the active area I, and the front humidifier 12 or the rear humidifier 13 carry out the process for the added gas. For "humidification" treatment, there is an electrode plate between the humidifier and the basic unit. With the increase of the required output voltage, the basic units of the fuel cell must be continuously increased, resulting in defects such as increased internal gas pressure difference, uneven gas distribution, and easy spontaneous combustion in the active area I basic unit group. like Figure 3-6 As shown, the basic unit group is composed of basic units, and the area where the basic units are located is called the active area. The present invention arranges a dividing plate 5 in the active region I, and the basic unit group is divided into two basic unit subgrou...

Embodiment 2

[0055] Based on embodiment one, Figure 7 It is a single-inlet, single-outlet proton exchange membrane fuel cell stack diagram. Figure 8 It is a layered structure diagram of a single-inlet and single-outlet proton exchange membrane fuel cell. Figure 9 It is a front cover diagram of a single-inlet and single-outlet proton exchange membrane fuel cell. Figure 10 It is a diagram of the rear cover plate of a single-inlet and single-outlet proton exchange membrane fuel cell. Figure 11 It is a single-inlet, single-outlet proton exchange membrane fuel cell separator diagram. like Figure 7 As shown, the fuel cell consists of a front cover plate 1 and a rear cover plate 2 sandwiching a basic unit group, a front humidifier 12, and a rear humidifier 13. The basic unit group is composed of basic units, and the basic unit is a collection of membrane electrodes. body and gas deflectors attached to both sides of the membrane electrode assembly; a separator 5 is provided in the middle...

Embodiment 3

[0058] Based on embodiment two, Figure 12 It is a single inlet, double outlet proton exchange membrane fuel cell stack diagram. Figure 13 It is a layered structure diagram of a proton exchange membrane fuel cell with single inlet and double outlet. Figure 14 It is a diagram of the rear cover plate of a proton exchange membrane fuel cell with single inlet and double outlet. Figure 15 It is a single inlet, double outlet proton exchange membrane fuel cell separator diagram. The front cover plate of the single inlet, double outlet proton exchange membrane fuel cell is the same as that of the single inlet, single outlet proton exchange membrane fuel cell.

[0059] like Figure 14 As shown, based on the single-inlet and single-outlet proton exchange membrane fuel cell rear cover, the single-inlet and double-exit proton exchange membrane fuel cell adds two gas outlets on the rear cover 2: the rear Z gas outlet 16 and the rear Y gas outlet 17. like Figure 15 As shown, based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com