Plate blank electroslag furnace

An electroslag furnace and slab technology, applied in the field of slab electroslag furnace, can solve the problems of incomplete controlled rolling equipment, low rolling pressure, small compression ratio, etc., so as to improve the equipment power factor, increase the melting speed, reduce the The effect of loop inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

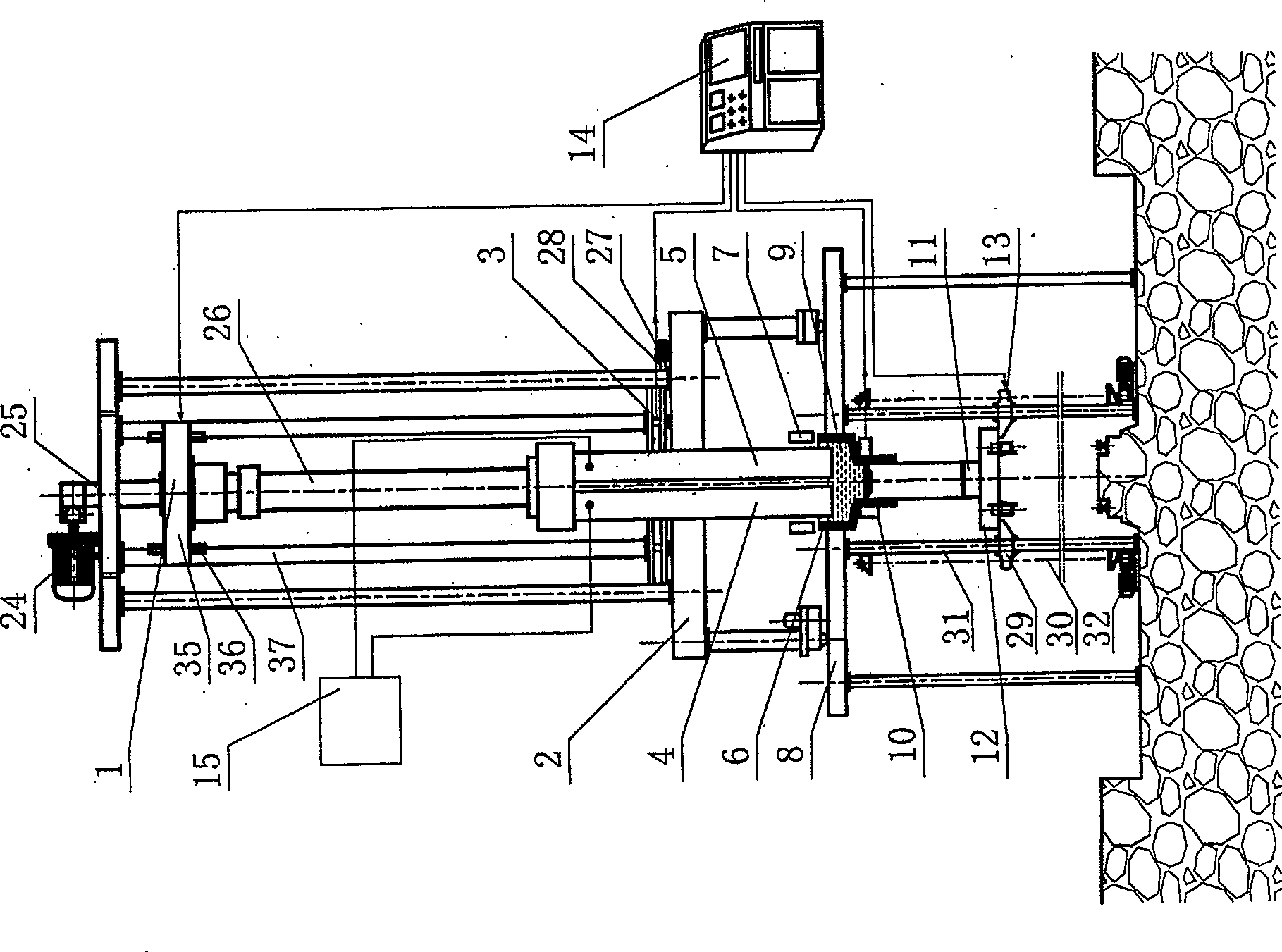

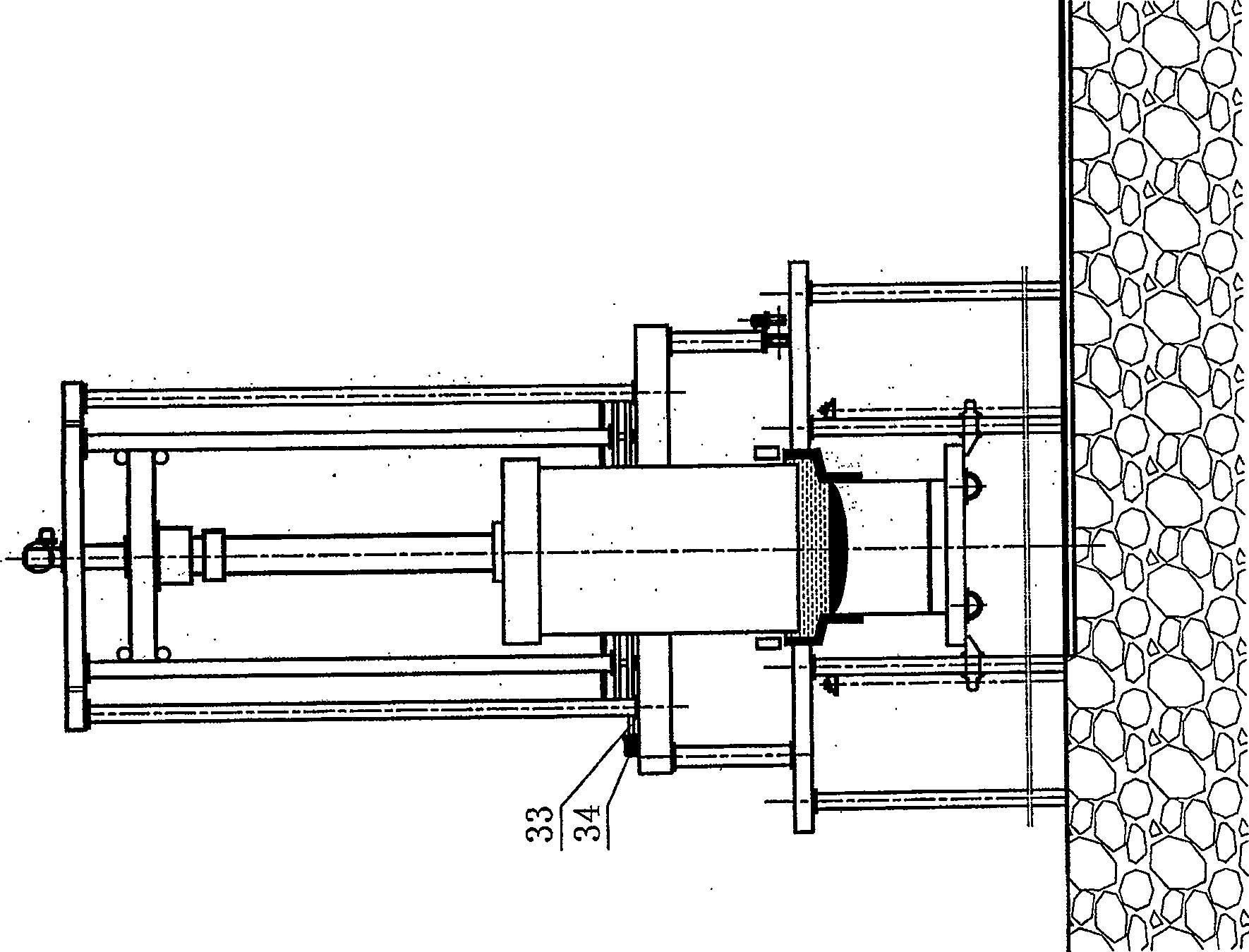

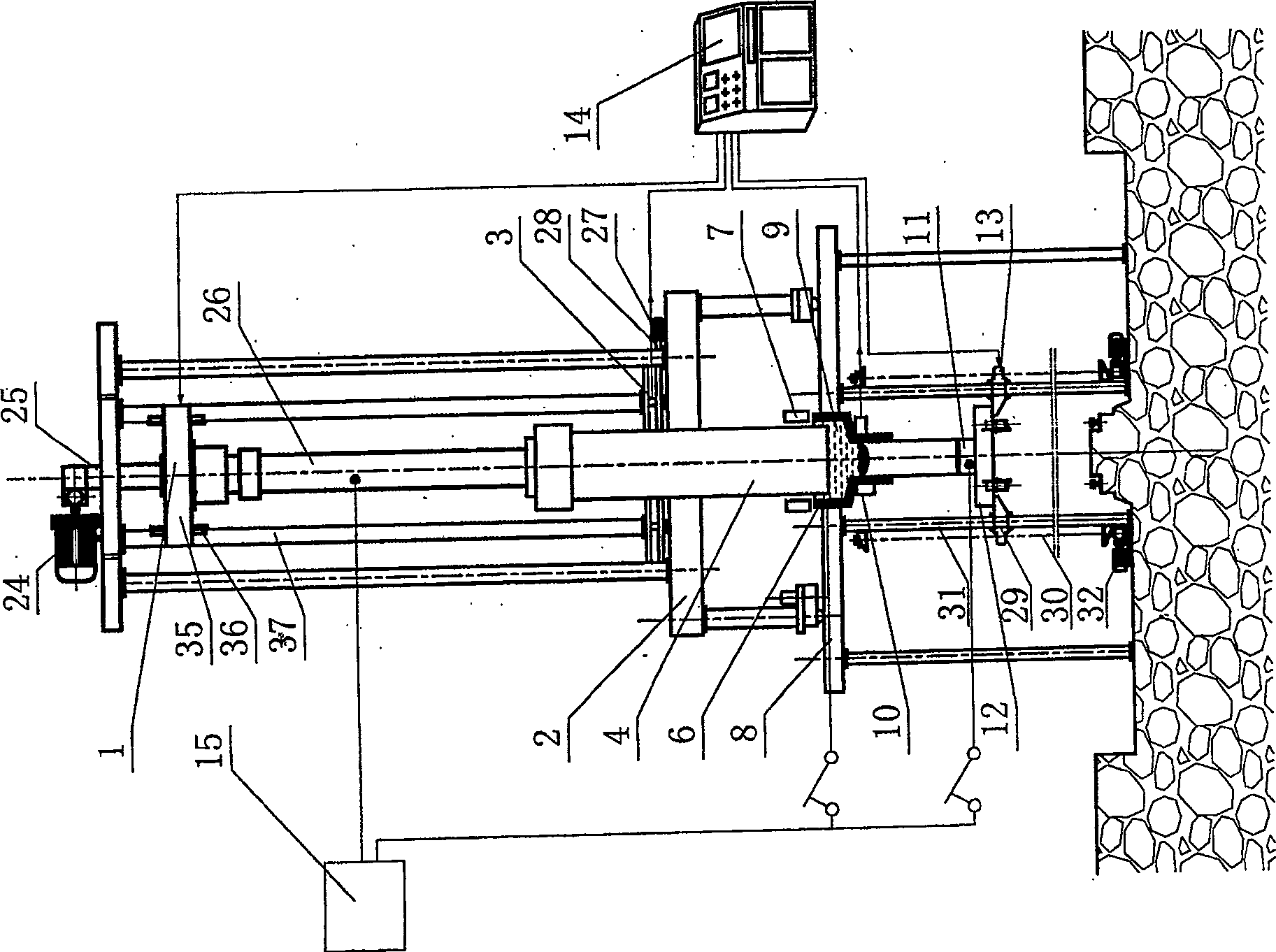

[0046] Embodiment 1: The crystallizer in the present invention adopts a T-shaped crystallizer, the power supply is AC, and the power supply mode of bipolar series. Such as figure 1 , figure 2 As shown, it includes an AC power supply 15, an electrode lifting mechanism 1, a rotating frame 2, a load cell 3, an electrode I 4, an electrode II 5, a T-shaped crystallizer 6, a supporting platform 8, an ingot drawing mechanism 13, and an ingot device 11 , ingot transport trolley 12, molten steel liquid level detection device 10 and control system 14, crystallizer 6 is fixed on the support platform 8, is fixed with rotating frame 2 on support platform 8, and rotation frame 2 can be fixed along the support platform 8 The orbit rotates, and an adjustment mechanism is installed on the rotating frame 2 for adjusting the electrode lifting mechanism in the horizontal X and Y directions. The electrode lifting mechanism 1 is placed on the frame platform 18 in the rotating frame 2, and the el...

Embodiment 2

[0063] Embodiment 2: crystallizer among the present invention adopts unipolar, T-shaped conductive crystallizer, and the T-shaped conductive crystallizer that adopts is to be provided with conductive ring between crystallizer top and crystallizer bottom, crystallizer top and conductive ring Insulators are placed between the lower part of the crystallizer and the conductive ring; the insulator is made of ceramic material, and the conductive ring is made of copper. The power supply is AC, and the power supply mode is single-electrode, T-shaped crystallizer conduction. Such as image 3 , Figure 4 As shown, it includes an AC power supply 15, an electrode lifting mechanism 1, a rotating frame 2, a load cell 3, an electrode 14, a crystallizer 6, a support platform 8, an ingot drawing mechanism 13, an ingot device 11 and a control system 14. The device 6 is fixed on the supporting platform 8, and the rotating frame 2 is fixed on the supporting platform 8, and an adjustment mechani...

Embodiment 3

[0066] Embodiment 3: The crystallizer in the present invention adopts a bucket type crystallizer, the power supply is DC, and the power supply mode of bipolar series. Such as Figure 5 , Figure 6 As shown, it includes an AC power supply 15, an electrode lifting mechanism 1, a rotating frame 2, a load cell 3, an electrode I4, an electrode II 5, a T-shaped crystallizer 6, a supporting platform 8, an ingot drawing mechanism 13, an ingot device 11, The ingot conveying trolley 12, the molten steel level detection device 10 and the control system 14, the crystallizer 6 is fixed on the supporting platform 8, the rotating frame 2 is fixed on the supporting platform 8, the adjusting mechanism is installed on the rotating frame 2, and the electrodes are lifted and lowered. The mechanism 1 is placed on the frame platform 18 in the rotating frame 2, and a load cell 3 is placed between the contact surface of the electrode lifting mechanism 1 and the frame platform 18, the model is 1-RTNA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com