Method of producing hard alloy rotatable special-shaped blade

A cemented carbide, special-shaped technology, applied in the field of powder metallurgy, to achieve the effect of reducing the operation process, keeping the shape intact, and avoiding secondary oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

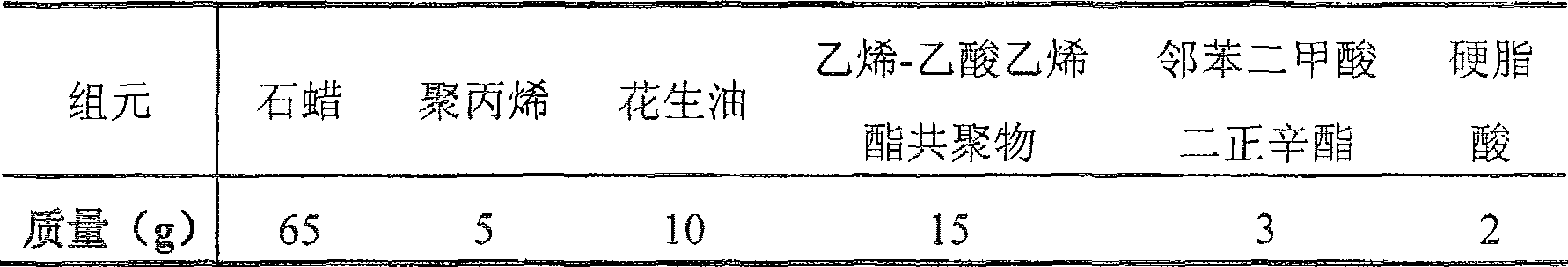

[0019] (1) Weigh the mass of each binder component according to the mass percentage ratio (take 100g binder as an example):

[0020]

[0021] Mix each component on the internal mixer to form a uniform color mixture, which is the binder used;

[0022] (2) Weigh 2000g of WC-6Co cemented carbide powder and 98.5g of binder according to the powder volume loading (such as 55%), and mix the powder and binder for 2 hours in an internal mixer to prepare a well-mixed feeding;

[0023] (3) Inject the feed material on the injection machine to produce the injection blank of the indexable special-shaped blade. During the injection process, the injection temperature is 120°C, the injection pressure / holding pressure is 110MPa, the injection time is 2 seconds, and the holding time is 0.5 seconds, the injection speed (flow rate) is 50%, and the storage position is 10.00mm;

[0024] (4) Solvent degreasing the injection billet in solvent gasoline, the degreasing temperature is 35°C, and the ...

Embodiment 2

[0030] (1) Weigh the mass of each binder component according to the mass percentage ratio (take 100g binder as an example):

[0031]

[0032] Mix each component on the internal mixer to form a uniform color mixture, which is the binder used;

[0033] (2) Weigh 2000g of WC-10Co cemented carbide powder and 98.5g of binder according to the powder volume loading (such as 51%), mix the powder and binder in an internal mixer for 1h, and prepare a well-mixed feeding;

[0034] (3) Inject the feed material on the injection machine to produce an indexable special-shaped blade injection blank;

[0035] (6) Solvent degreasing the injection billet in solvent gasoline, the degreasing temperature is 26°C, and the degreasing time is 16h;

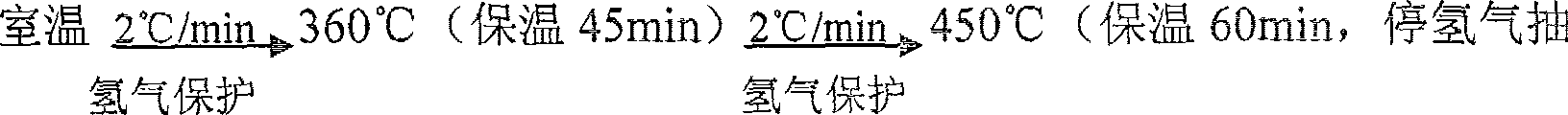

[0036] (7) Thermally degreasing and sintering the solvent degreasing billet in a thermal degreasing + sintering integrated furnace, and the thermal degreasing + sintering process is specifically as follows:

[0037]

[0038]

[0039] (6) Perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com