Round pipe steel component arc clod curving forming mould

A technology of cold forming and steel components, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of flattening distortion in the diameter direction, crushing and wrinkling, and affecting the strength of steel components, so as to reduce flattening Distortion, reducing crimping and wrinkling, and ensuring the quality of the bend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

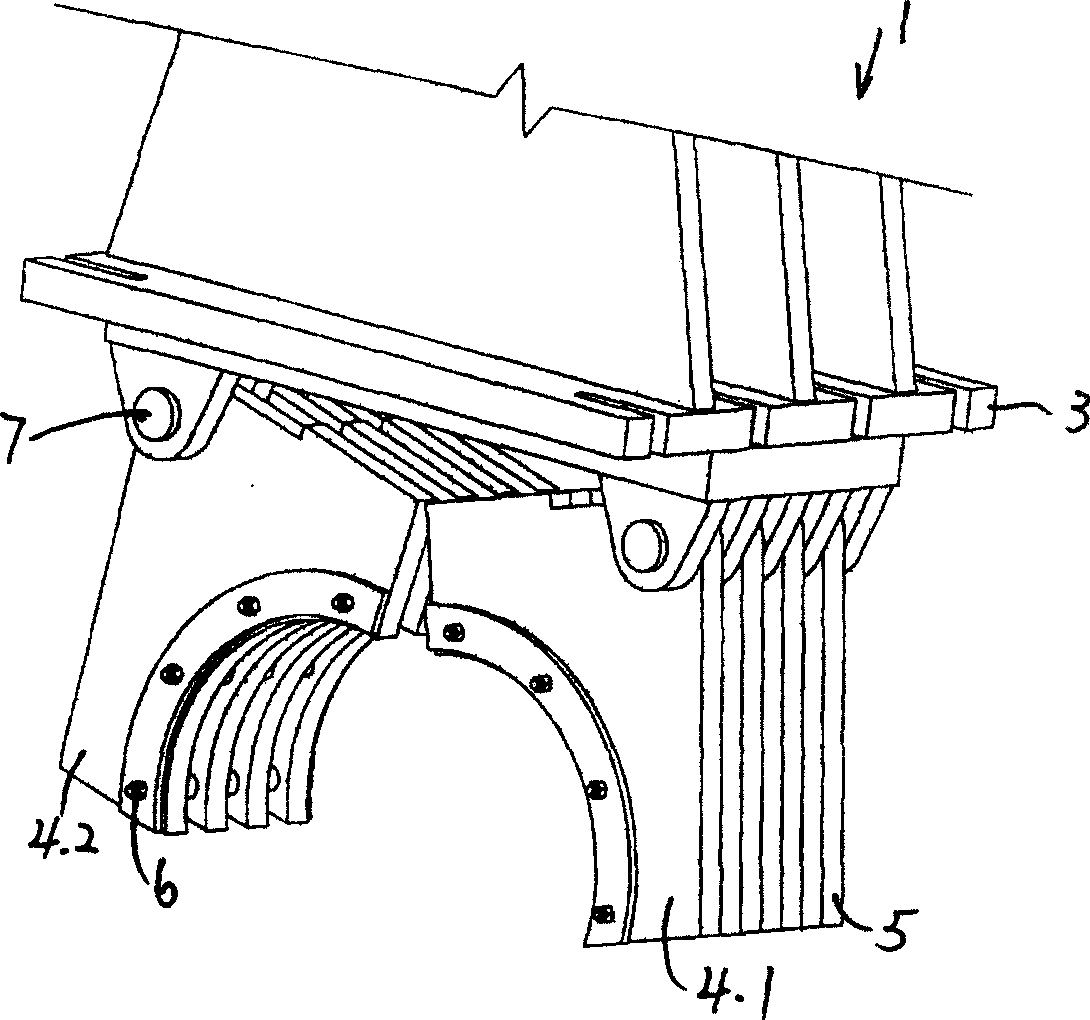

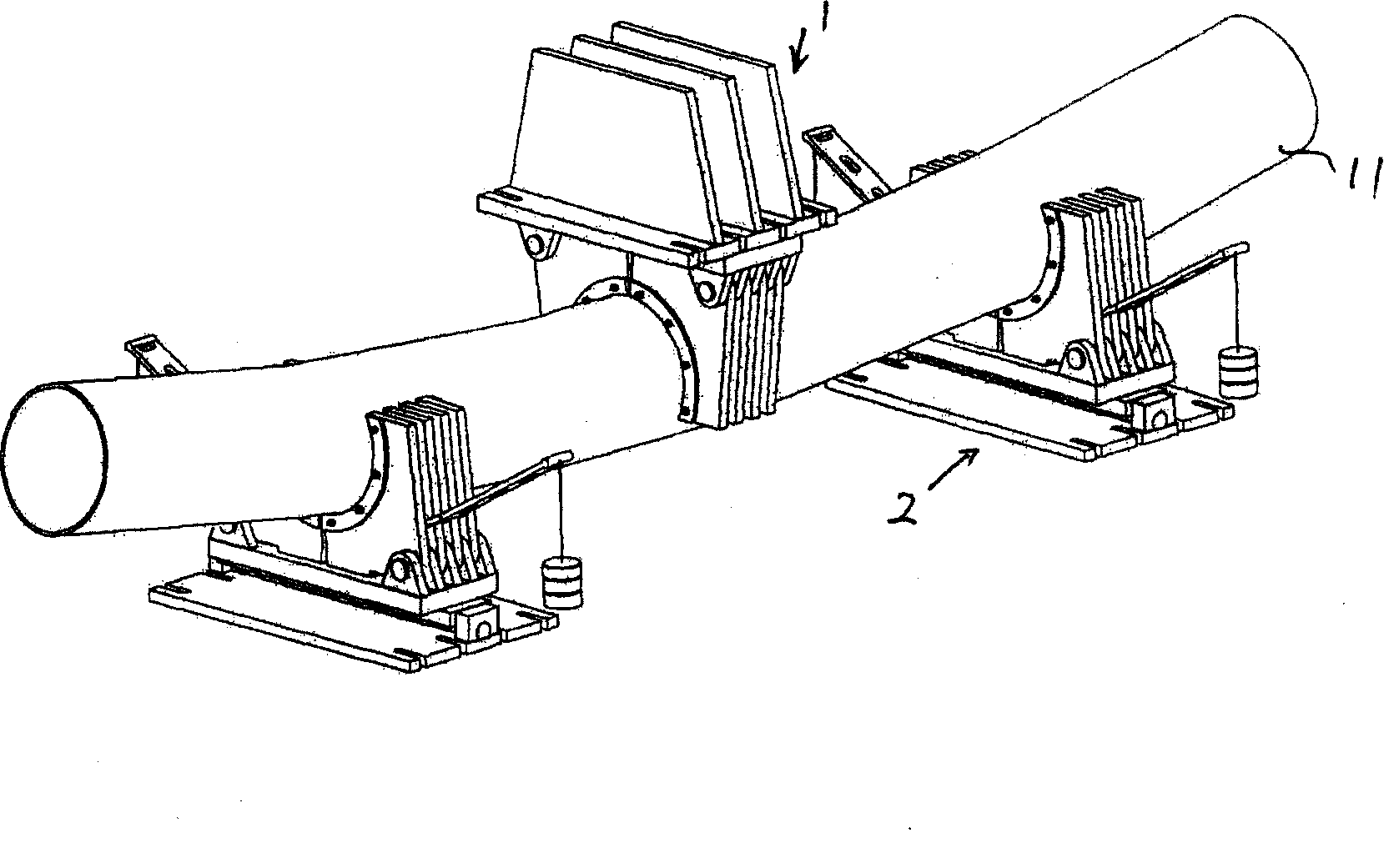

[0019] Embodiment 1: see figure 1 , 2 , upper mold 1 and lower mold 2 of the present invention, respectively have mold supporting plate 3 and the left and right two petals movable arc-shaped mold valves 4.1 and 4.2 that are movably arranged on it to form. Among them: the total arc length of the left and right two arc-shaped closing envelopes is 2 / 3-3 / 4 arc length of the circumferential surface of the bent steel pipe, and the movable arc-shaped mold petals are composed of 8 arc-shaped steel plates with a thickness of 80mm and 5 axial phases. Parallel, connected in series by 6 pin shafts, each piece is separated by 80mm lug plate. The outer sides of the left and right two arc-shaped mold halves are roughly right-angled, and the corners are arc-shaped. The right-angled parts are supported by the movable pin of the shaft 7 on the mold support plate 3. There are counterweight levers 8 on the left and right mold halves of the lower mold for skid movement. The mold opens. The uppe...

Embodiment 2

[0023] Embodiment 2: As in Embodiment 1, the separation / closing of the left and right arc-shaped mold halves can also be done by moving horizontally on the mold support plate. / Push to open / close.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com