A kind of nylon tube automatic heating forming equipment and forming process

一种自动加热、成型设备的技术,应用在尼龙管成型领域,能够解决易发生缓慢伸展、温度降低、弯管精度下降等问题,达到保证成型质量、防止转动和扭曲、加工效率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

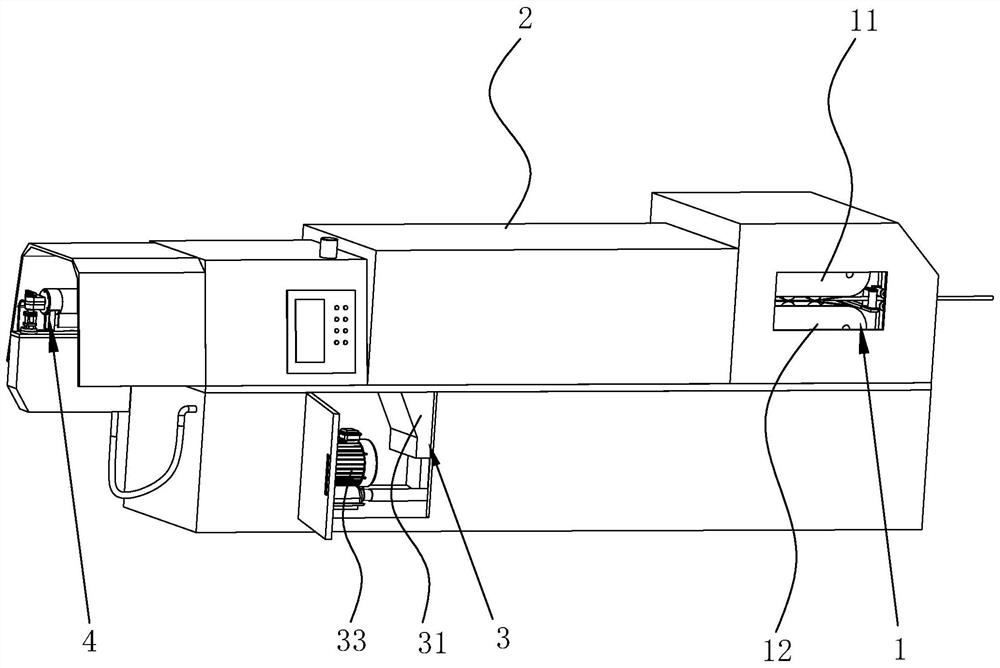

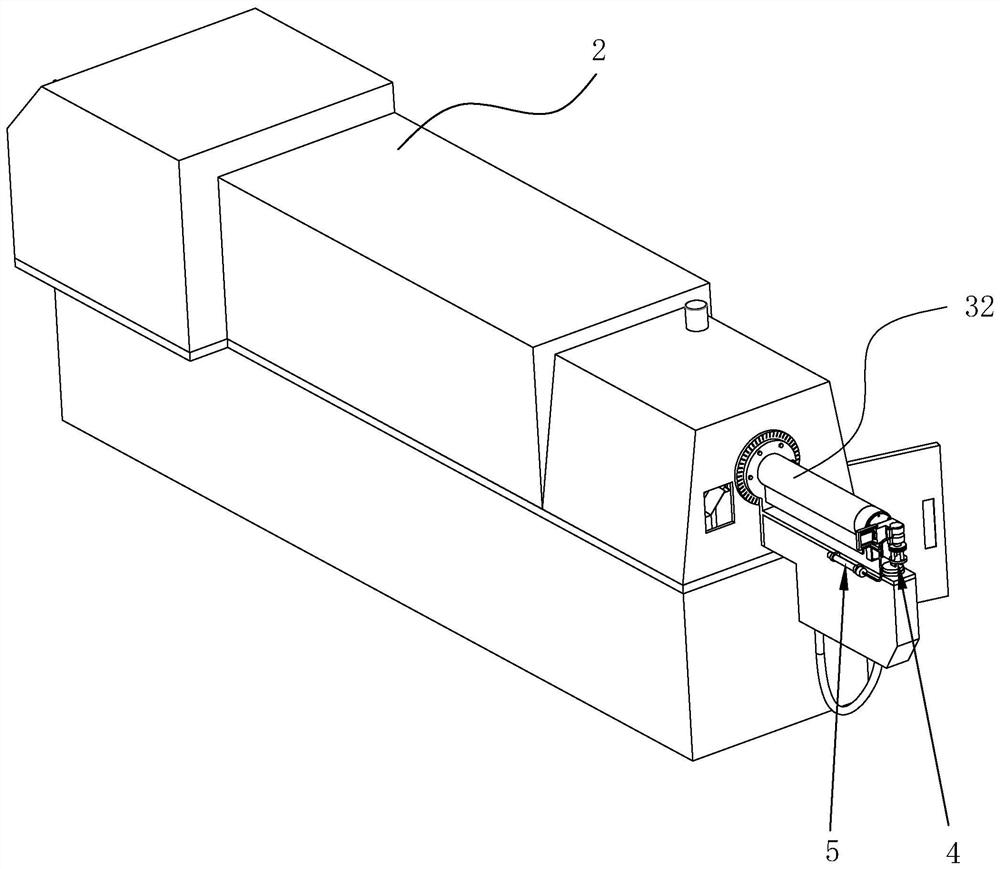

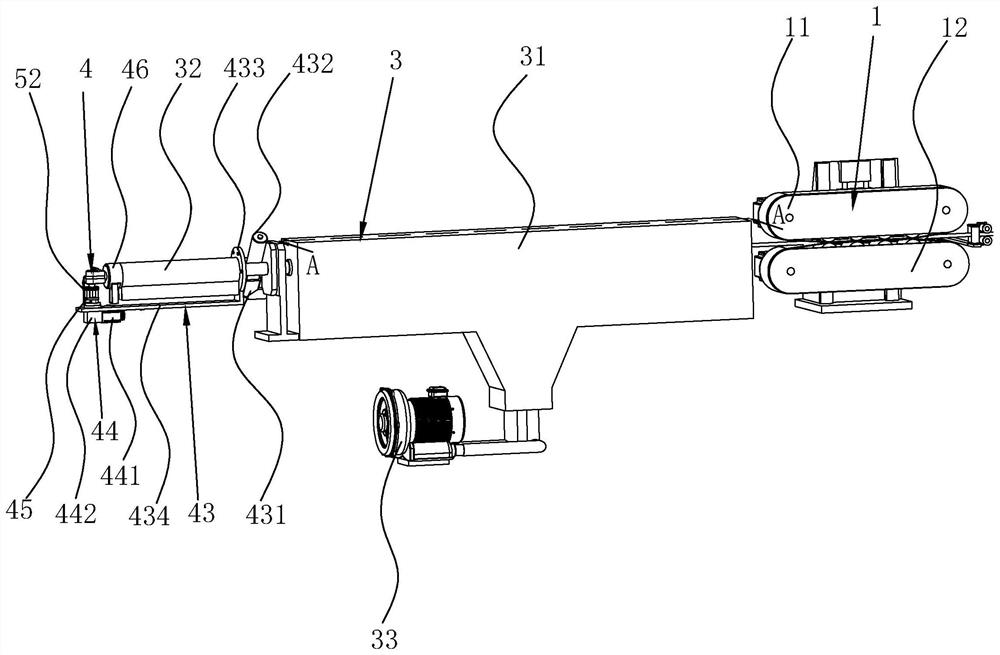

[0056] refer to figure 1 , figure 2 , image 3 , is an automatic heating and forming equipment for nylon tubes disclosed in the present invention, comprising a fuselage 2, a feeding assembly 1, a heating assembly 3 and a pipe bending assembly 4 sequentially arranged in the fuselage 2, and the heating assembly 3 includes and The oven 31 connected to the feeding assembly 1 and the electric heating cylinder 32 arranged between the oven 31 and the elbow assembly 4, the electric heating cylinder 32 is provided with a heating ring, and the nylon tube is fed from the feeding assembly 1 and passed through the oven 31 and the electric heating cylinder 32 and enter the elbow assembly 4, the electric heating cylinder 32 and the elbow assembly 4 are arranged outside the fuselage 2, as a part of the heating assembly 3, so that the heating assembly 3 does not protrude in the oven 31 In the case of the outside of the fuselage 2, the nylon tube protruding from the outside of the fuselage 2...

Embodiment 2

[0069] refer to Figure 10 , This embodiment of the present invention discloses a nylon tube forming process, including the nylon tube automatic heating and forming equipment in embodiment 1, which includes the following process steps:

[0070] S1: lead wire, manually feed the end of the coiled nylon tube between the upper conveyor belt 11 and the lower conveyor belt 12 in the feeding assembly 1, so that the feeding assembly 1 continuously pulls the pair of nylon tubes;

[0071] S2: heating inside the fuselage 2, and the nylon tube is heated through the oven 31;

[0072] S3: external heating of the fuselage 2, the nylon tube is heated outside the fuselage 2 through the electric heating cylinder 32;

[0073] S4: Bending, start the second drive assembly 44 to drive the elbow assembly 42 to rotate at a certain angle to press the nylon tube into the bending groove 414;

[0074] S5: stop, the elbow assembly 42 keeps the state of pressing the nylon tube into the bending groove 414...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com