Construction method for prefabricated tubular pile with expanding head

A technology of prefabricated pipe piles and construction methods, applied in sheet pile walls, soil protection, infrastructure engineering and other directions, can solve the problems of difficulty in guaranteeing engineering quality, difficulty in concrete pouring, and difficulty in forming expansion heads, etc., to achieve fast construction, improve physical Mechanical index, effect of reducing the number of piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

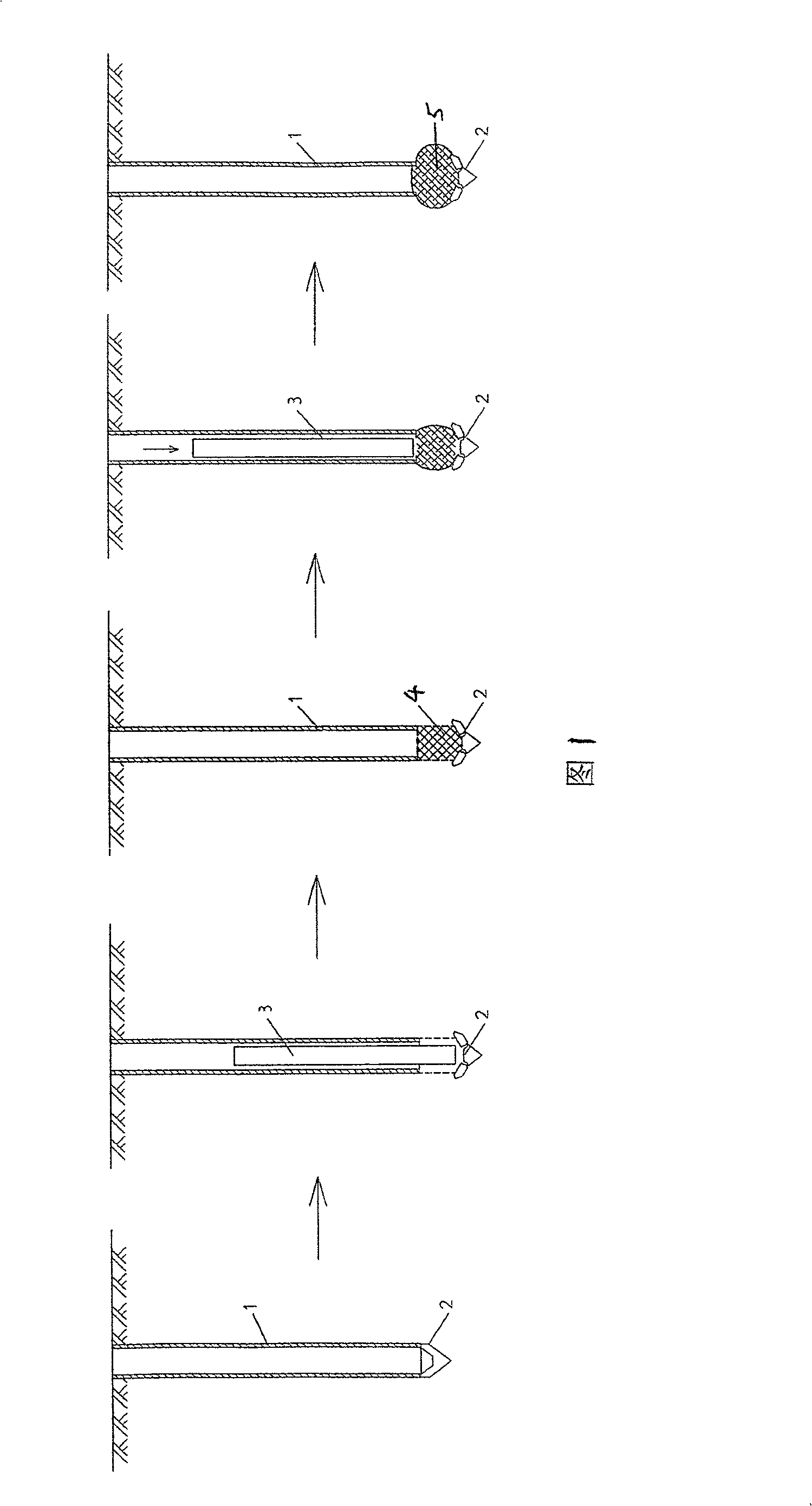

[0015] Example of companding method: prefabricated pipe piles have an outer diameter of Φ500mm, an inner diameter of Φ340mm, and a pile length of 12m. After measuring, positioning and setting out, place the special pile tip, and then use a 400-ton static pressure pile machine to press the prefabricated pipe pile and the special pile tip to the predetermined elevation, and ram the pile tip with a heavy hammer with a diameter of 300mm. Make the pile tip sink 700mm (so that there is a 700mm gap between the pile tip and the pipe pile), then fill in 800mm high gravel, and then ram the gravel with a heavy hammer to make it expand around, and so on Repeatedly, until the hammering penetration reaches the design standard, and finally pour 0.2 cubic meters of C30 concrete, thus forming the enlarged head, and completing the construction of the prefabricated pipe pile with the enlarged head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com