Linear type heat treatment furnace

A heat treatment furnace, linear technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of increasing cleaning processes and cleaning equipment, longer loss time, and high cost, shortening waiting time, preventing atmosphere fluctuations, extending The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the drawings and examples.

[0046] In the drawings, the same symbols are used for the same components as those of the prior art.

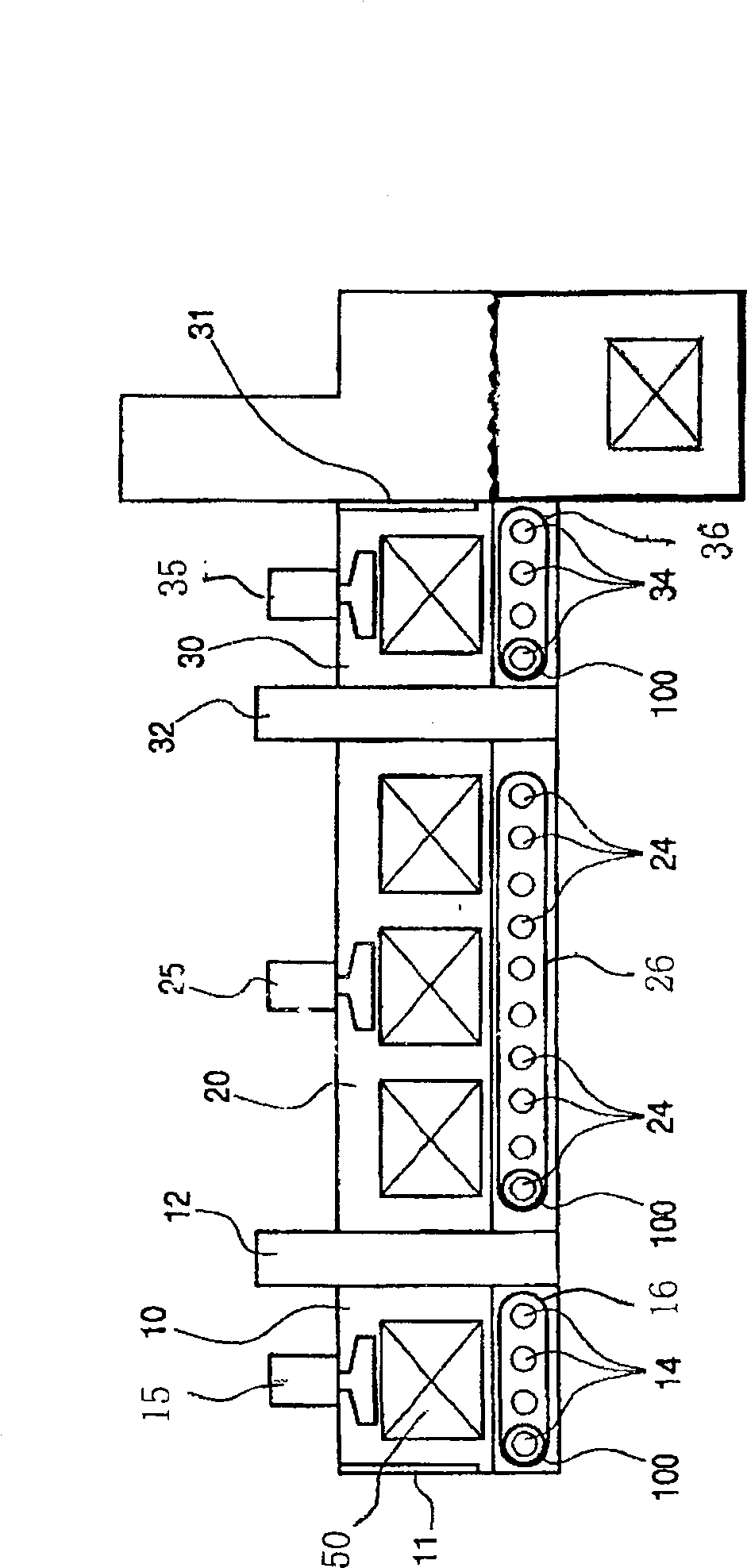

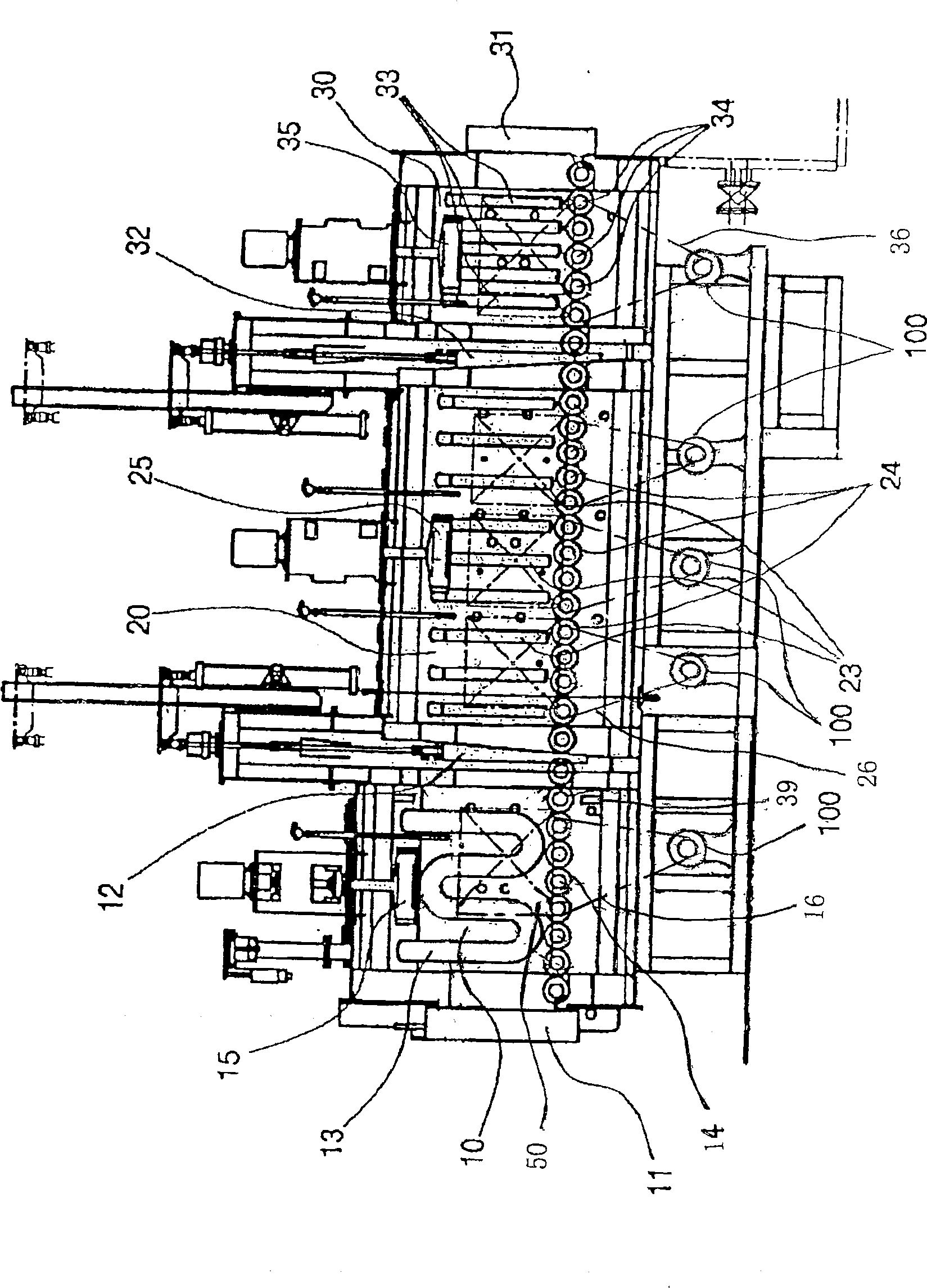

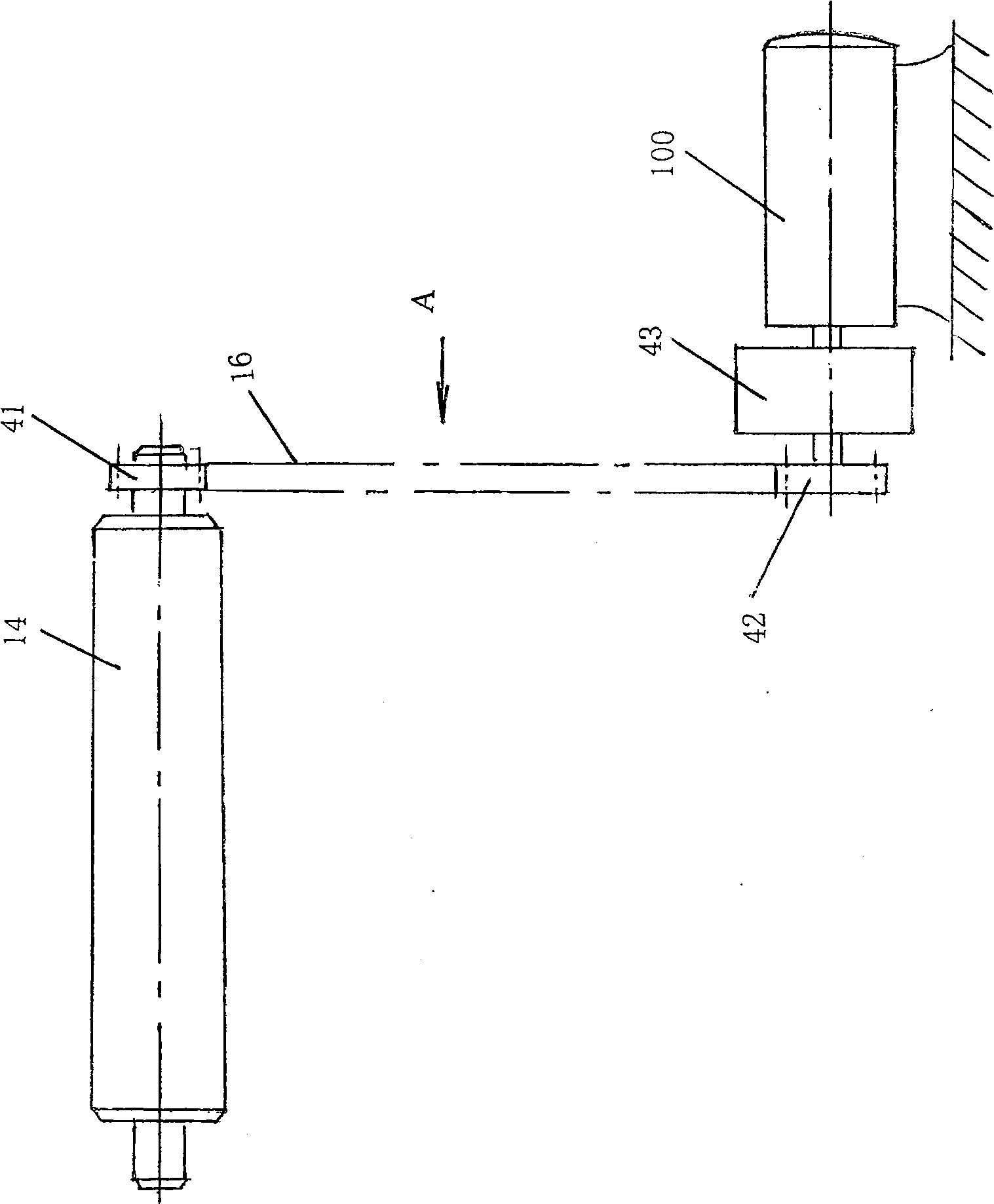

[0047] The linear heat treatment furnace of the present invention is as Figure 2 to Figure 5 as shown, figure 2 It is a structural schematic diagram of the linear heat treatment furnace of the present invention. Such as figure 2 As shown, the present invention is a linear heat treatment furnace composed of a preheating chamber 10, a heat treatment chamber 20 and a quenching chamber 30. First of all, let me explain one thing: each room and each station are in the figure 2 , Figure 5 is represented by a square frame surrounded by dotted lines.

[0048] The preheating chamber 10 forms a sealed space by the entrance door 11 that cuts off the loading port for loading the workpiece 50 from the outside, and the first partition door 12 that separates the heat treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com