Lathe dedicated for boring on pipe fittings flange

A special machine tool and flange technology, applied in the field of special machine tool equipment for pipe flange drilling, can solve the problems of reduced life, easy wear of drill bits and drill sleeves, increased labor intensity of operators, etc., and achieves simple processing technology and assembly technology. , to solve the effect of low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

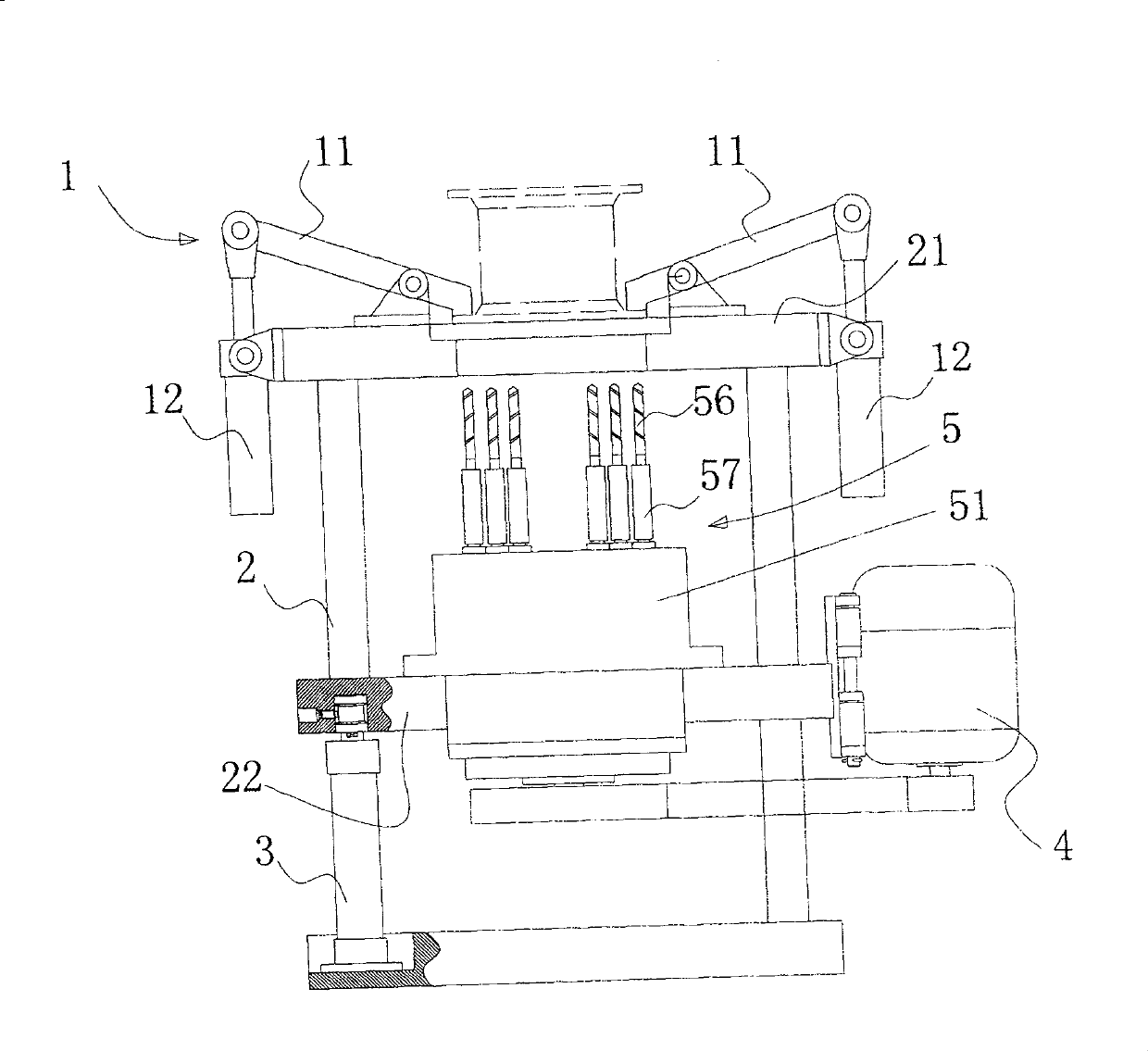

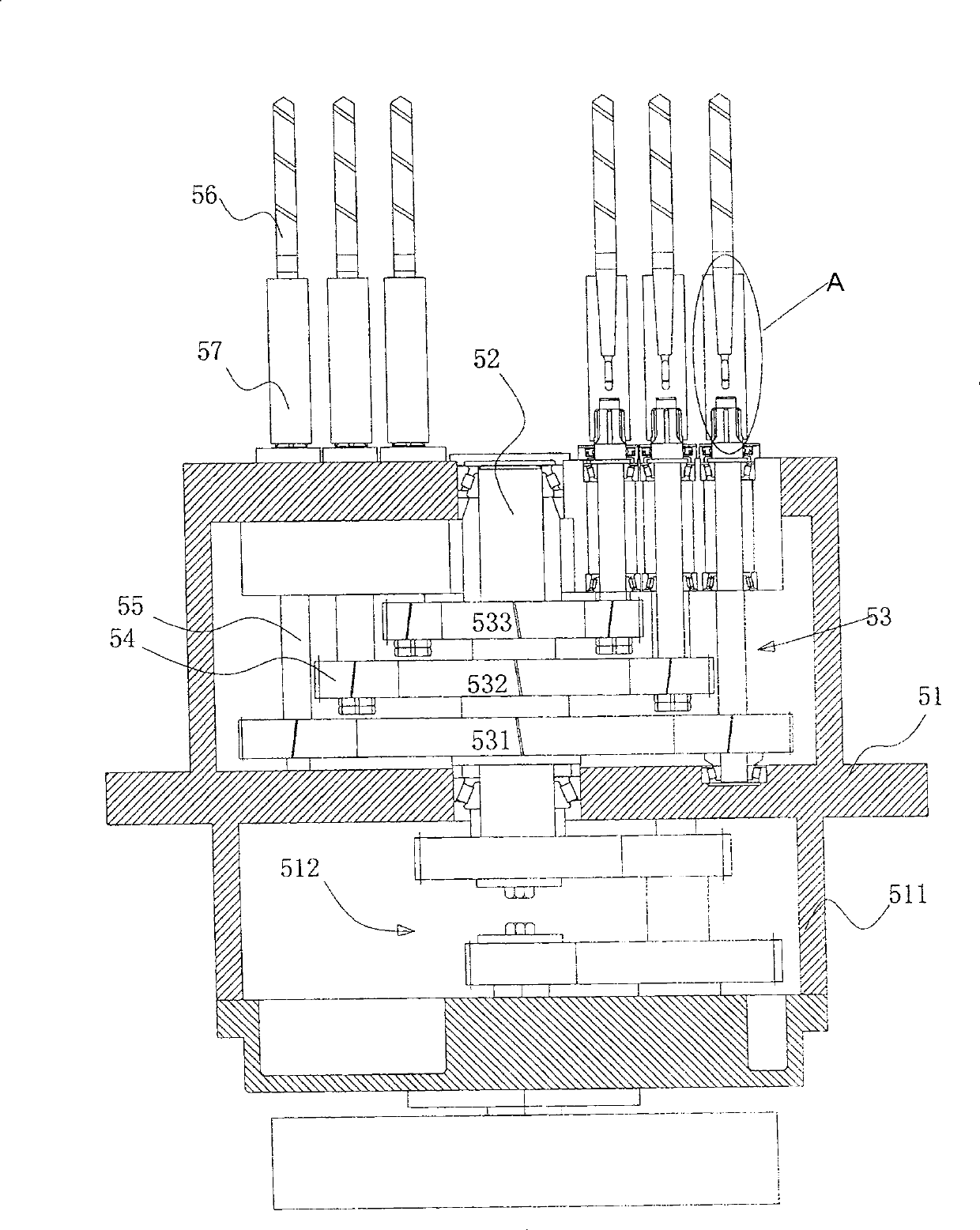

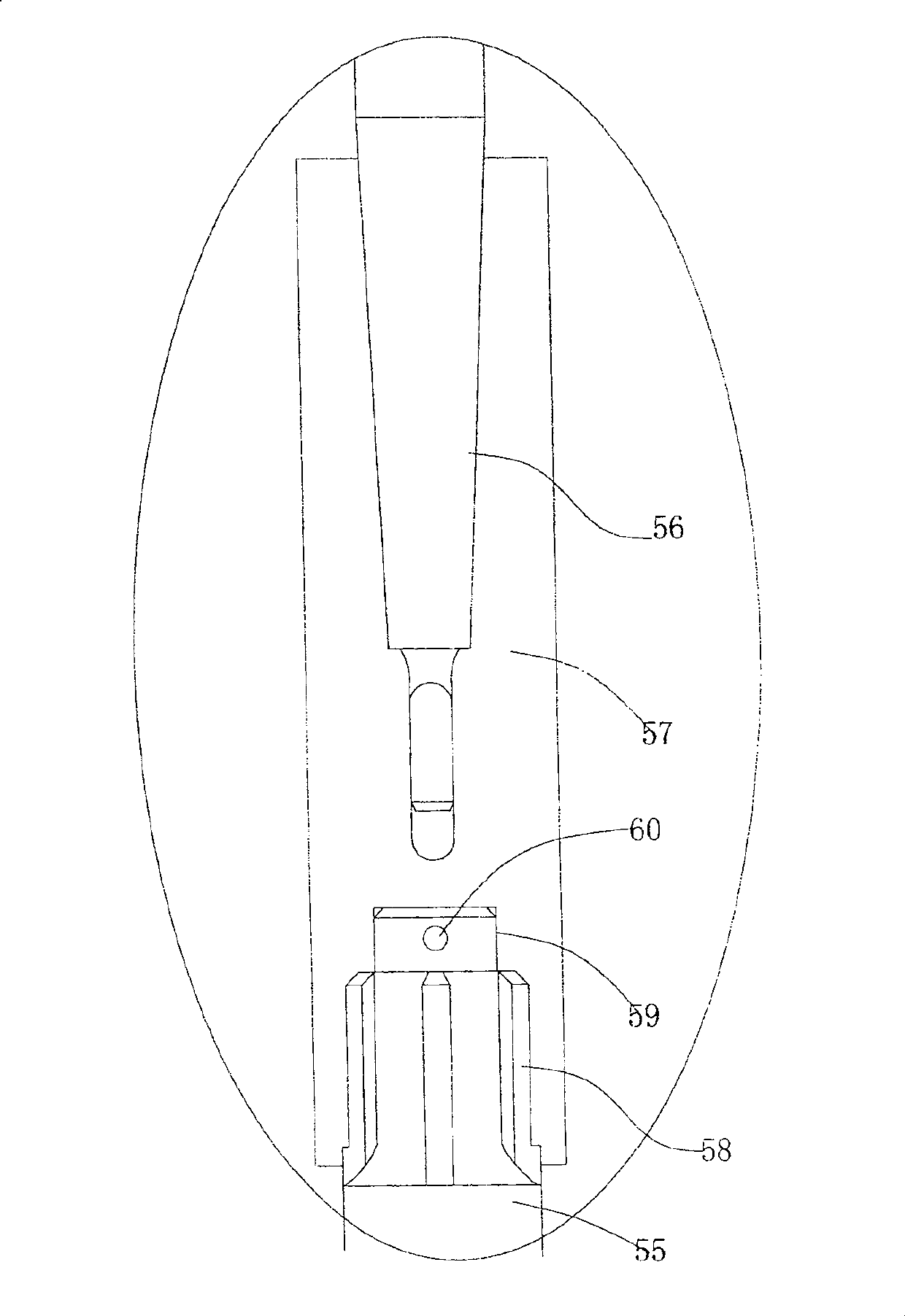

[0035] The invention provides a special machine tool for drilling holes in pipe fitting flanges, referring to figure 1 and figure 2 , the special machine tool mainly includes: fixture part 1, frame part 2, hydraulic system 3, electromechanical transmission system 4, multi-axis power head part 5, and the multi-axis power head 5 further includes: spindle box 51, main drive shaft 52 , Tower-shaped gear set 53, this tower-shaped gear set further includes three driving wheels 531 (large), 532 (middle), 533 (small), and the planetary gears that are symmetrically distributed on the outer circumference of the three driving wheels and meshed with it 54 and the drilling main shaft 55 installed on the planetary wheel, the rotation of the drilling main shaft 55 (main movement) is transmitted to the reduction gear set 512 of the lower transmission case 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com