Method for producing cunninghamia lanceolata integrated material for outdoor

A production method and technology of laminated wood, which are applied in the direction of wood processing appliances, joining of wooden veneers, manufacturing tools, etc., can solve problems such as discomfort, and achieve the effect of eliminating internal stress and strong water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

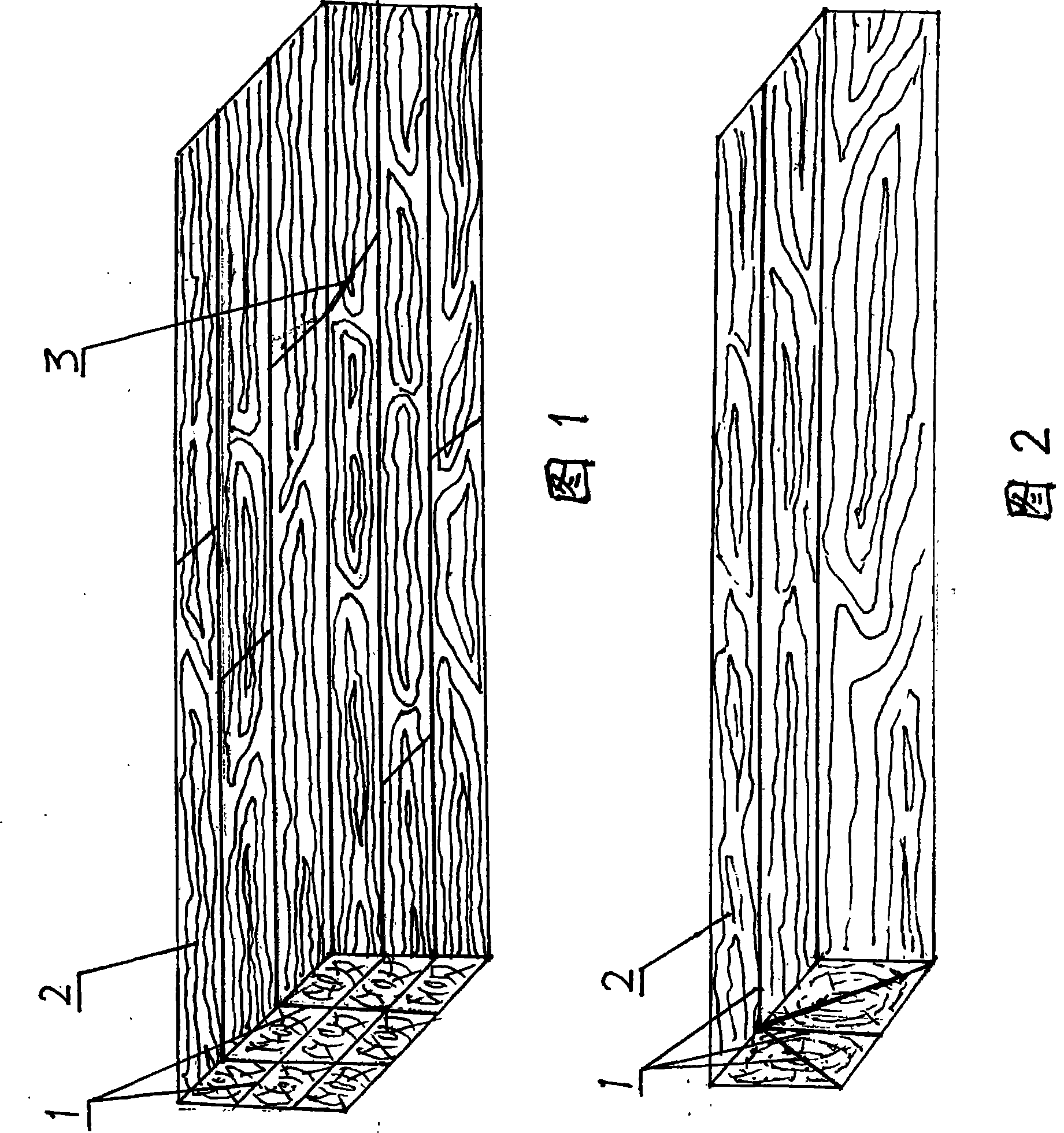

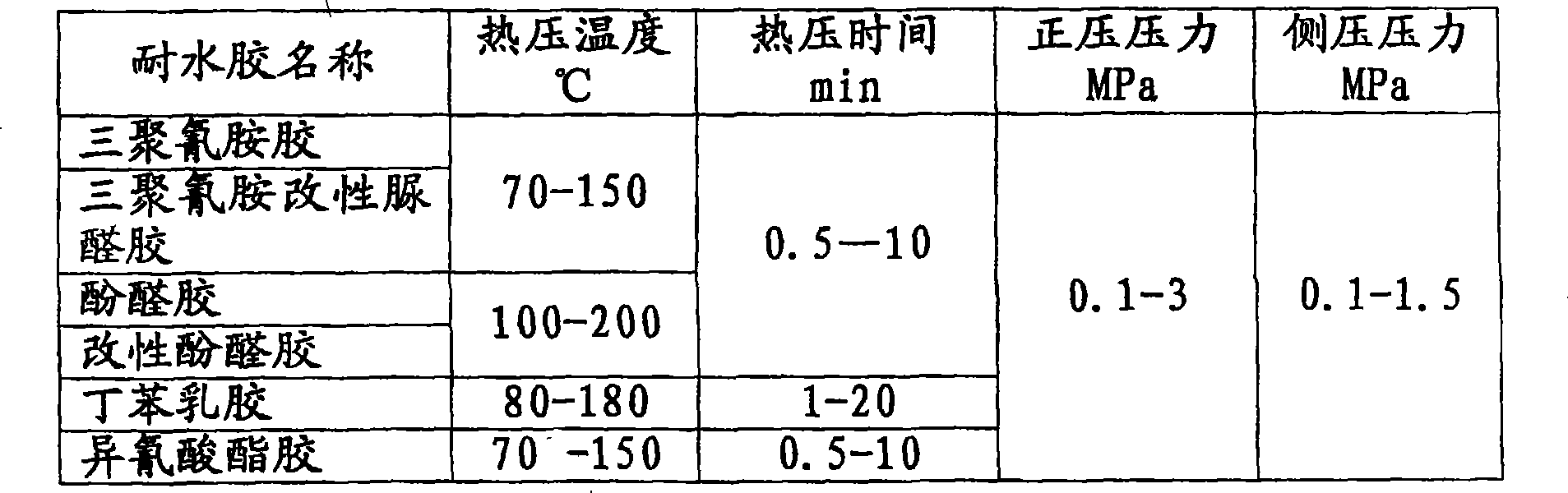

[0015] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments: First, the leftovers of fir logs with medium and small diameters or large-diameter fir that meet the specifications are cut to length as needed or according to the rational utilization of raw materials, and then enter the carbonization kiln for ventilated well-shaped Pile them up layer by layer, close the kiln door, turn on the heat source, and gradually raise the temperature from the kiln to 80°C. After the fir wood is dry, immediately raise the temperature to above 130°C. Sampling and visually inspect the carbonization degree of the fir wood or weigh it. The light brown color of the fir wood is Micro-carbonization, medium brown is moderate carbonization, dark brown is heavy carbonization, which is not advisable. During micro-carbonization, the equilibrium moisture content of Chinese fir is almost 1 / 2 of that of general dryness. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com