Structure of amorphous alloy iron core dry distribution transformer body

A technology of distribution transformers and amorphous alloys, applied in transformers, fixed transformers, transformers/inductor coils/windings/connections, etc., can solve the problem of large no-load loss of transformers, reduce material consumption, and strengthen insulation , the effect of compact body structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

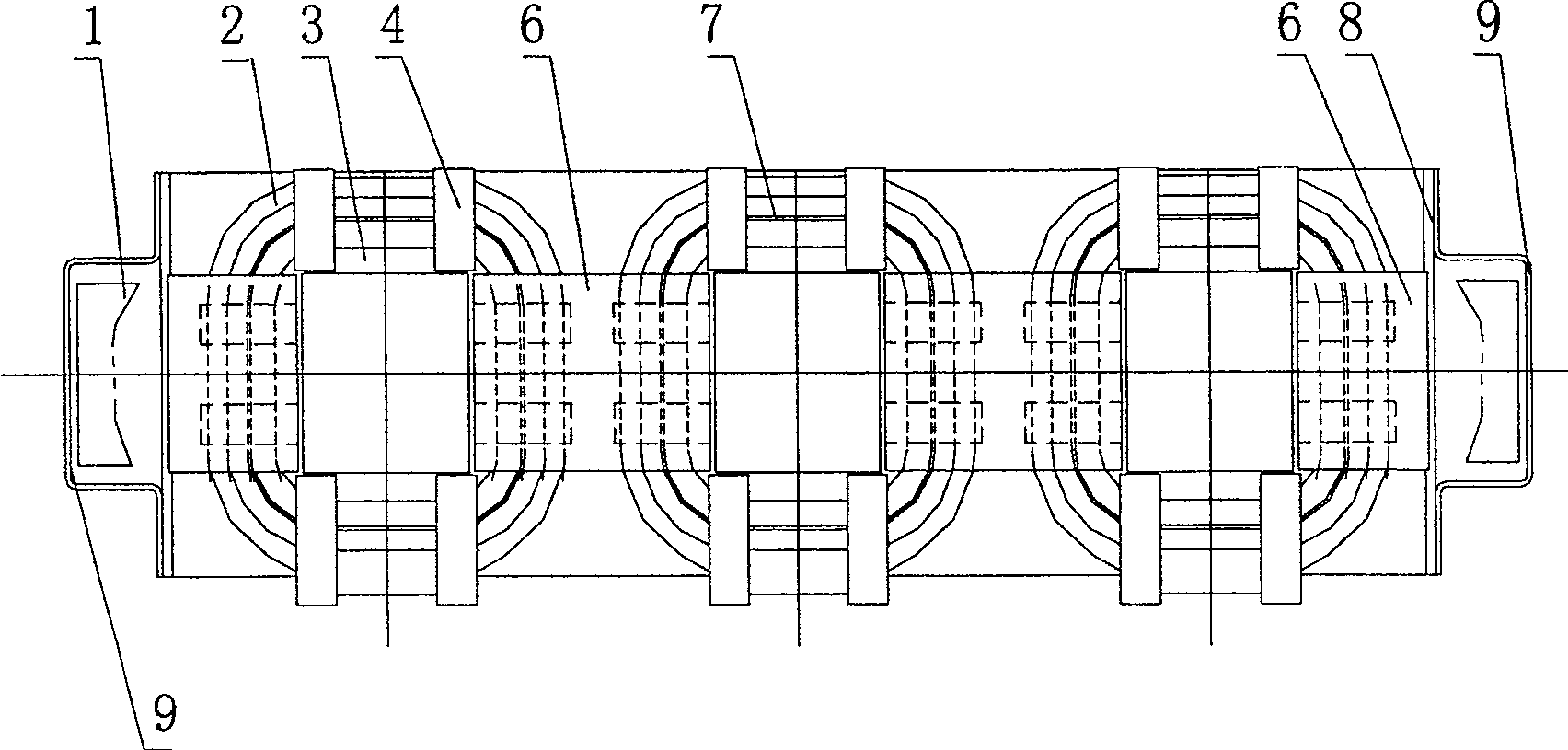

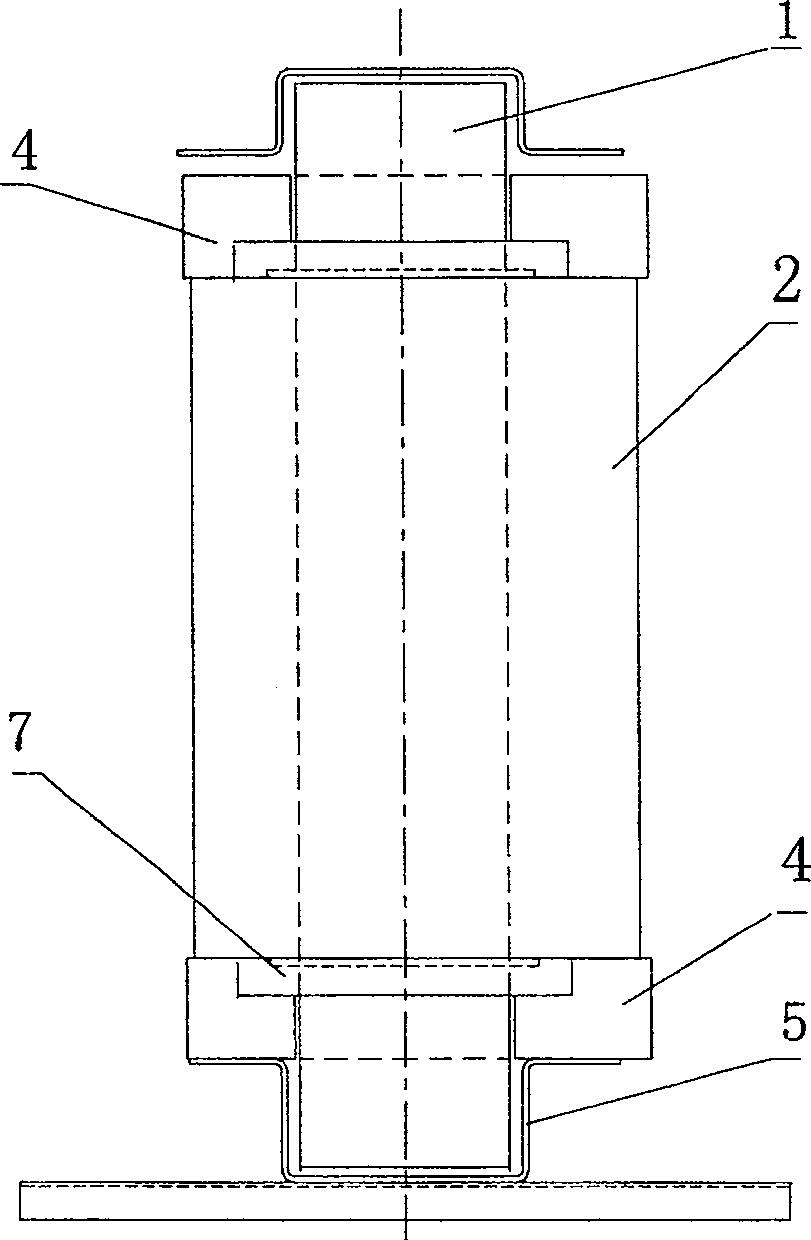

[0012] Such as Figure 1~2 As shown, it is an embodiment of the present invention (that is, the body structure of an amorphous alloy iron core dry-type distribution transformer), which is a four-frame and five-column structure, and is especially suitable for amorphous alloy iron core dry-type distribution transformers with a voltage level of 35kV. Electric transformer.

[0013] The body structure of the amorphous alloy iron core dry-type distribution transformer includes an amorphous alloy iron core 1, high and low voltage coils 2 and 3 arranged in coaxial layers, upper and lower clamps 5, insulating support plates 6 and two The end clips 9, wherein: the upper and lower clips 5 and the two end clips 9 form a rigid frame structure.

[0014] The characteristics of the present invention are: first, an insulating cylinder 7 is provided between the high and low voltage coils 2 and 3; There are several insulating briquetting blocks 4 respectively distributed between them, that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com