Modified grounding anti-corrosion resistance reduction agent

A technology of anti-corrosion and resistance-reducing agent and bentonite, which is applied in the direction of connecting contact materials, compositions for inhibiting chemical changes, non-metallic conductors, etc., can solve problems such as poor corrosion resistance of grounded metal bodies, and achieve low cost and stable chemical properties. , the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with embodiment.

[0014] An improved anti-corrosion and drag-reducing agent for grounding, which is composed of sodium bentonite and graphite, and the weight percentage of each component is: 50-99% of sodium bentonite, 1-50% of graphite, and the main elements in sodium bentonite The weight percentage content is silicon oxide: 40-70%, titanium oxide 0.01-3%, iron oxide 0.5-9%, aluminum oxide 2-20%, calcium oxide 1-7%, potassium oxide 0.1-6%, sodium oxide 1-6%, the fixed carbon content in graphite is 60-90%. Crush and grind the sodium bentonite, mix it with graphite powder and mix thoroughly. It can use dry compress method and wet compress method, generally mainly wet compress method. Prepare a large piece of iron sheet at the construction site, pour the drag reducing agent on it, add water and stir it evenly with a shovel, and then lay the drag reducing agent around the grounding body. The constructi...

PUM

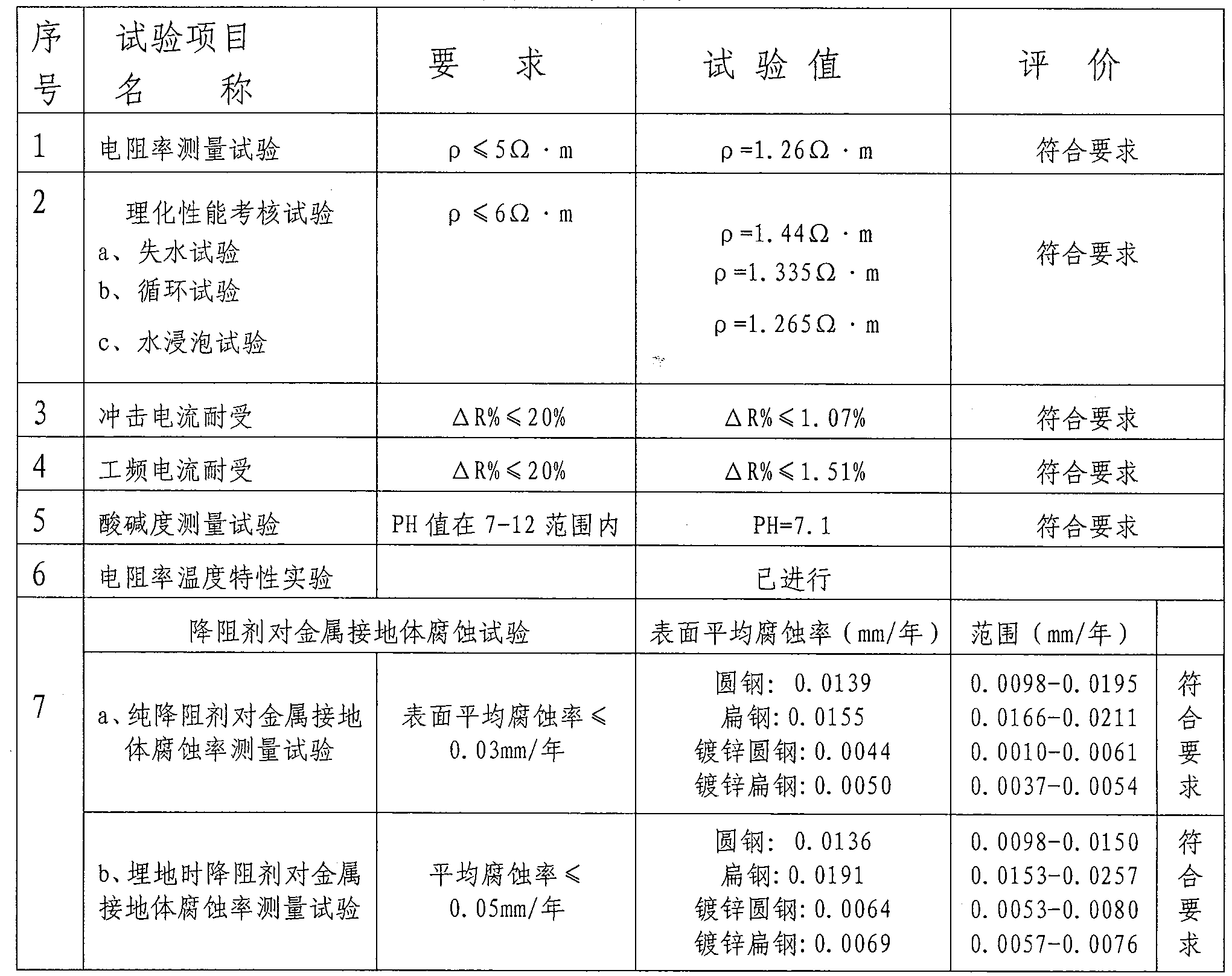

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com