Helical self-circulating bioreactor

A bioreactor and self-circulation technology, applied in chemical instruments and methods, settling tanks, water/sludge/sewage treatment, etc., can solve problems affecting matrix transformation, reactor failure, etc., to achieve enhanced matrix degradation, strong hydraulic The effect of load (flow) impact and containment of short flow phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

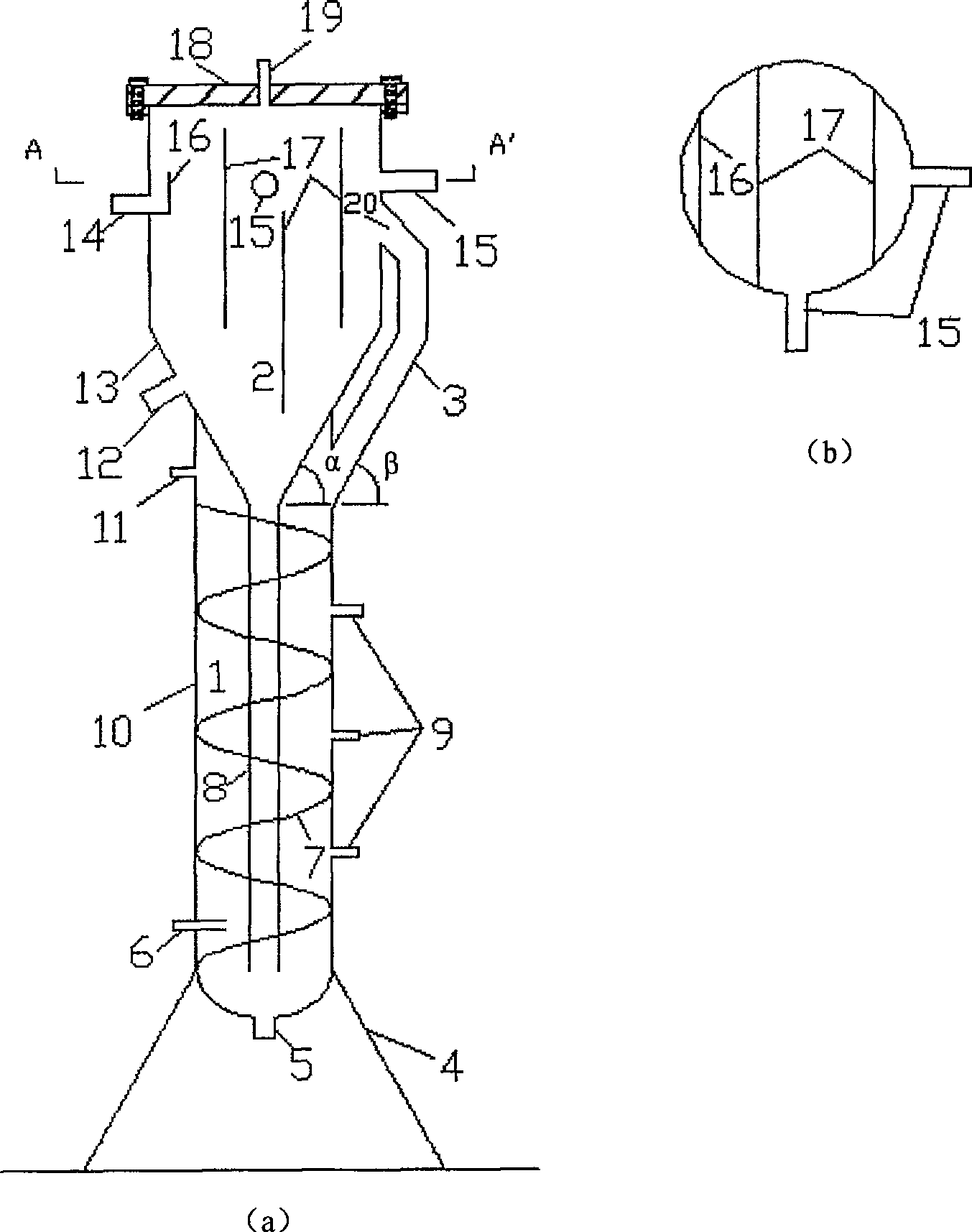

[0012] As shown in the accompanying drawings, the spiral self-circulation bioreactor has a reactor body and a bracket 4, and the reactor body is provided with a plug flow reaction chamber 1 and a baffle plate precipitation chamber 2 from bottom to top; The bottom is provided with a first row of mud pipe 5, the top of the plug flow reaction chamber 1 is provided with a second mud discharge pipe 11, and the center of the plug flow reaction chamber 1 is provided with a return pipe 8, which is arranged from bottom to top with the return pipe 8 as the axis. There are multi-layer spiral plates 7, and the bottom of the spiral plate 7 is provided with a water inlet pipe 6; the lower end of the baffle plate sedimentation chamber 2 is an outer cylindrical expanding pipe 13, and a third mud discharge pipe 12 is arranged in the middle of the outer cylindrical expanding pipe 13, The outer cylindrical expanding pipe 13 is fixed on the upper end of the reaction chamber cylinder 16, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com