Method for preparing fluid ice by extracting solidification latent heat based on wall surface elastic deformation to strip ice

A technology of elastic deformation and fluid ice, which is applied in ice making, ice making, ice storage/distribution, etc. It can solve the problems of large transmission energy consumption, large equipment investment, and low service life, achieving high heat exchange efficiency and wide application , the effect of high cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0006] Specific implementation mode one: in conjunction with Figure 9, Figure 10 , Figure 11 , Figure 12 Describe this embodiment, the method for extracting the latent heat of solidification to produce fluid ice based on the elastic deformation of the wall to peel off the ice in this embodiment is completed by the following steps: a. The heat exchange carrier makes the water that has released heat form an ice layer 3 on the wall surface 2 of the elastic deformation body; The formed ice layer is cracked; c, the cracked ice crystal 5 is peeled off from the elastic deformation body wall 2 under the action of water flow, air flow or gravity; d, the peeled ice crystal 5 flows away with the water flow 6, thereby making the fluid On ice, the elastically deformable body returns to its original shape.

specific Embodiment approach 2

[0007] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the heat exchange carrier in step a of this embodiment is air, and the elastic deformable body is a solid elastic deformable body. Water can directly exchange heat with air, and the operation is very convenient.

specific Embodiment approach 3

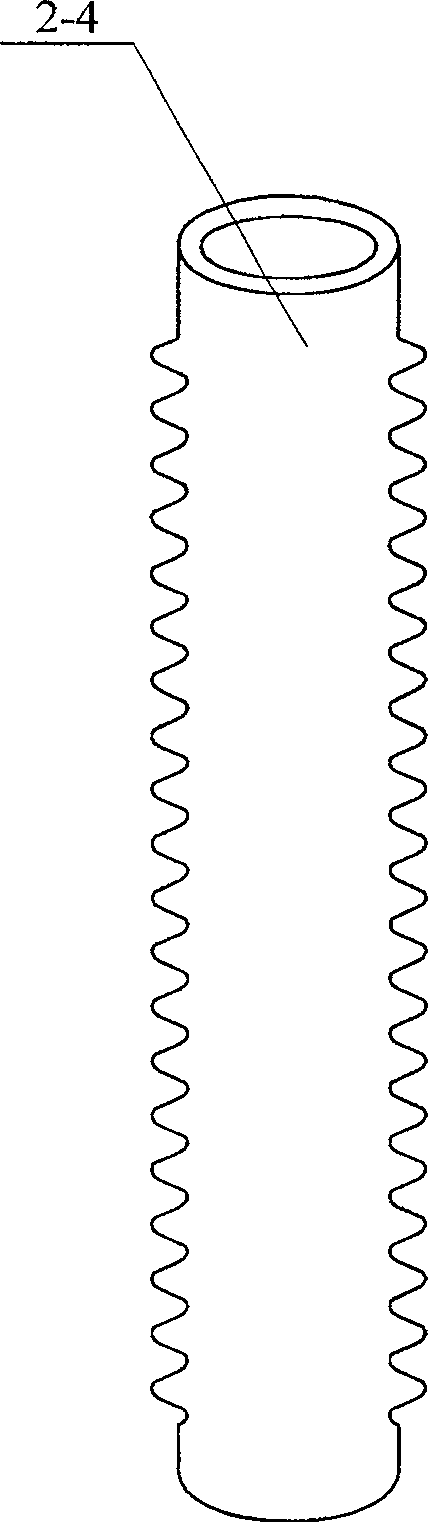

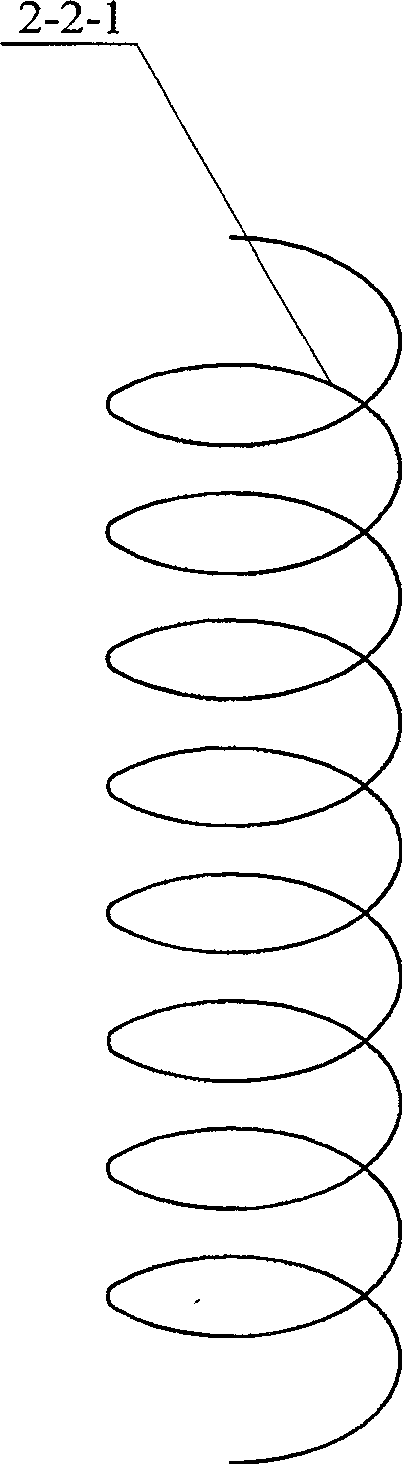

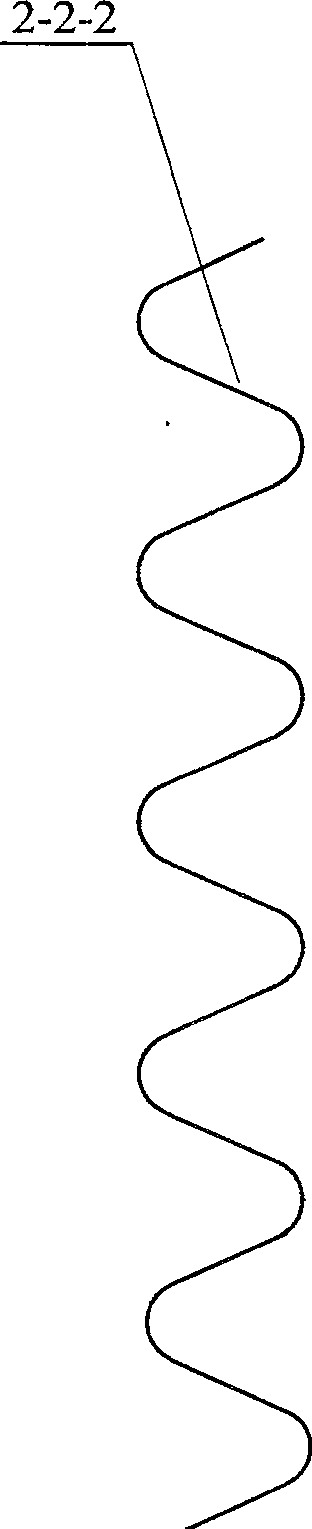

[0008] Specific implementation mode three: combination figure 2 , image 3 , Figure 5 , Figure 7 Describe this embodiment, the difference between this embodiment and specific embodiment two is: the solid elastic deformation body of this embodiment is a reed 2-1, a spring or a corrugated sheet 2-7; the spring is a coil spring 2- 2-1 or broken line spring 2-2-2. The solid elastic deformable body can adopt any one of the above elastic deformable bodies as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com