Deformation controlling method for sheet material in continuous heat treatment

A sheet material and high-temperature heating technology, which is applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of high labor intensity of workers, production in a single process, and inability to work continuously, and achieve obvious energy-saving effects, changes that cannot be continuously produced, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

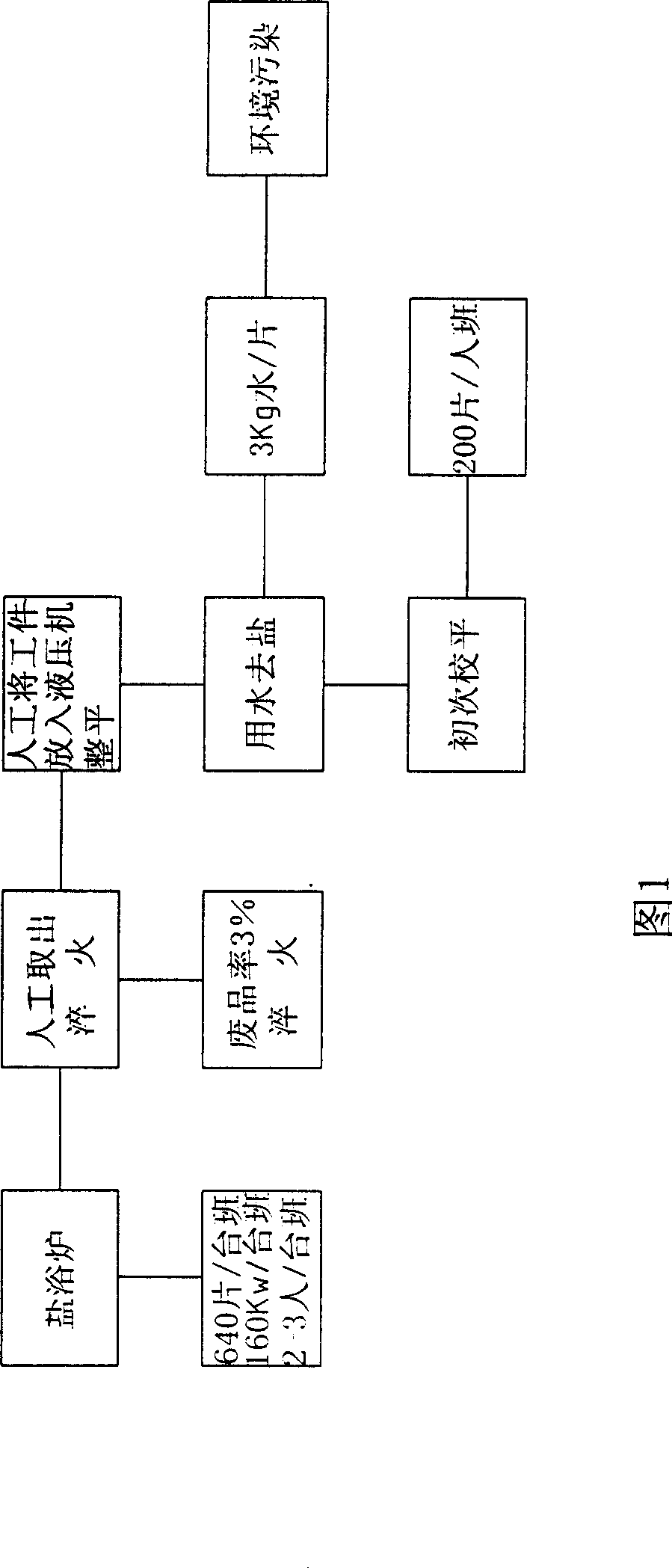

[0018] As shown in Figure 1, the schematic diagram of the existing production process of heat treatment of sheet materials has been described before and will not be repeated here.

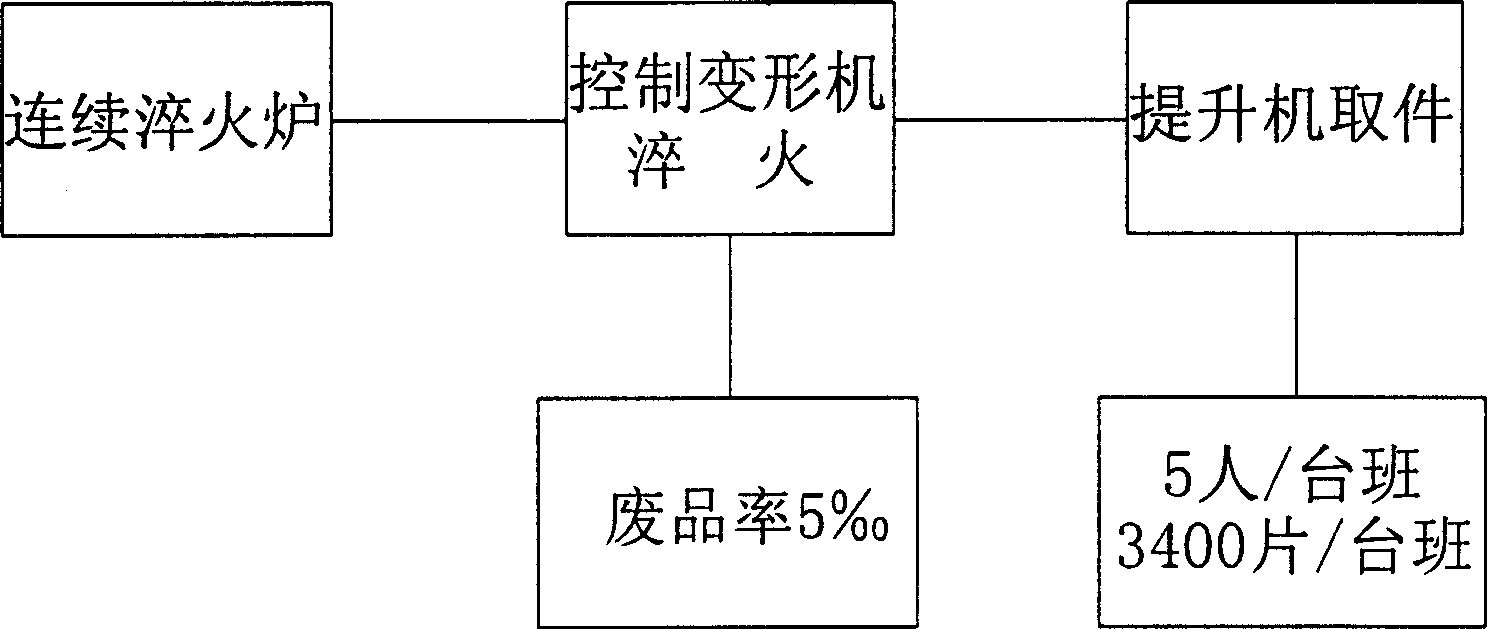

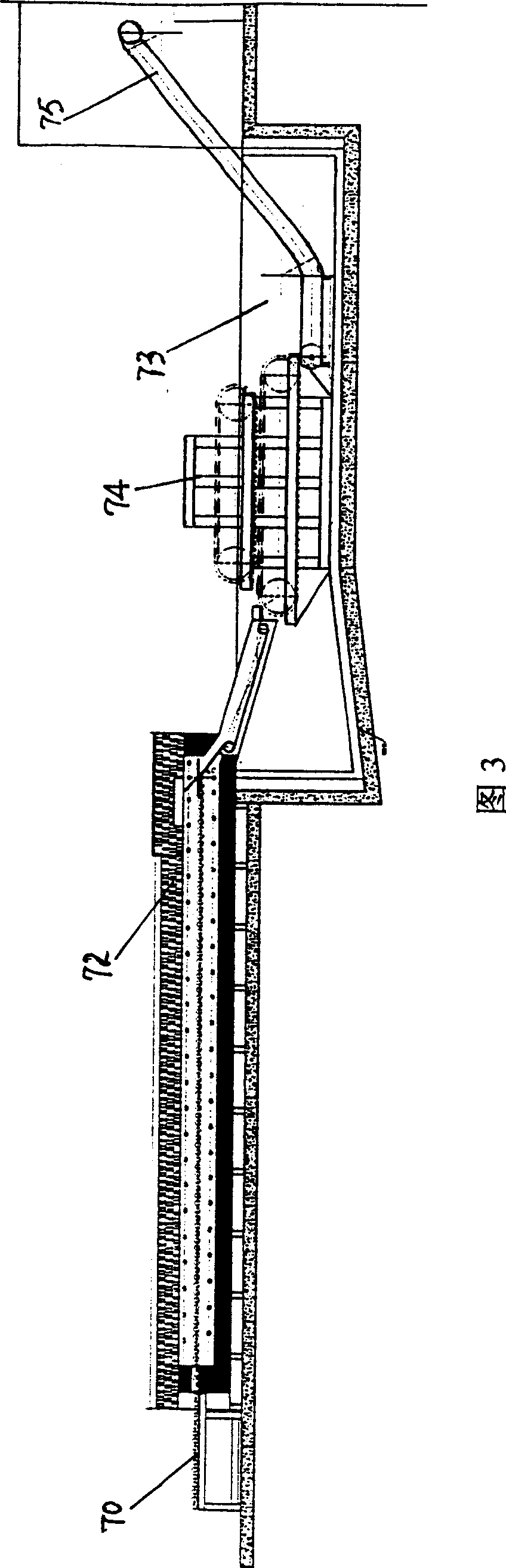

[0019] Such as figure 2 , 3, the process diagram of the present invention, the product blank is manually placed on the conveying roller 70, and the conveying roller 70 sends the blank to the roller bottom type continuous heating furnace 72 for heating, and the heated sheet passes through the conveying equipment 72 Automatically enter the cooling tank 73, that is, the sheet material continuous heat treatment control deformation equipment 74 in the quenching pool. After processing, the sheet material is output through the lifting transmission device 75 to leave the production line, that is, the sheet material after quenching is output to the quenching tank through the lifting transmission device.

[0020] As shown in Figures 4, 5 and 6, a pair of chain transmission devices 20 and 30 are set up and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com