Temp regulator of semiconductor substrate

A temperature adjustment device and semiconductor technology, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, and semiconductor/solid-state device components, etc., can solve the problem of reduced uniformity of temperature distribution, slower cooling of semiconductor substrates, and inability of air to escape smoothly. and other problems, to achieve the effect of suppressing warpage, rotation and lateral dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

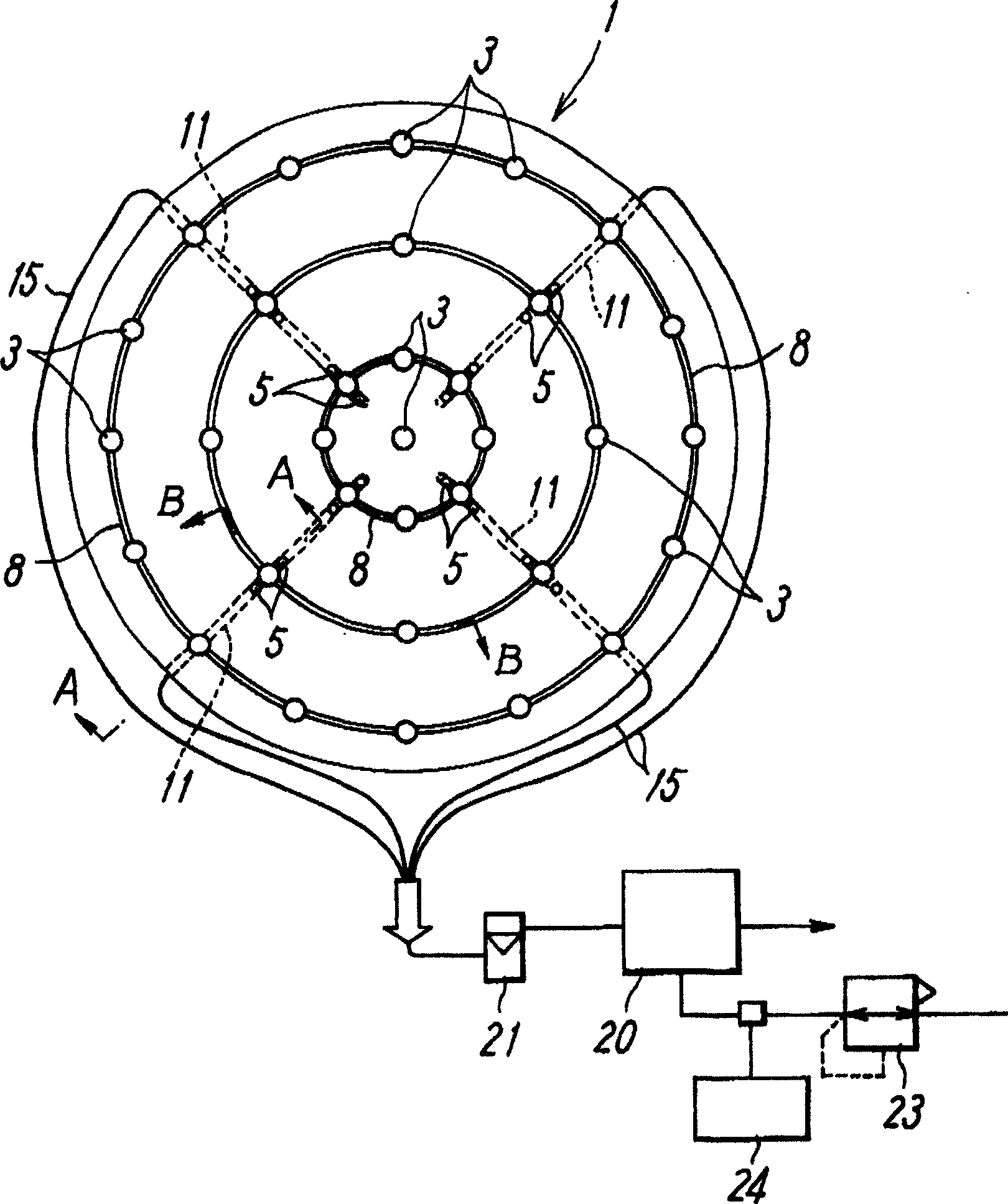

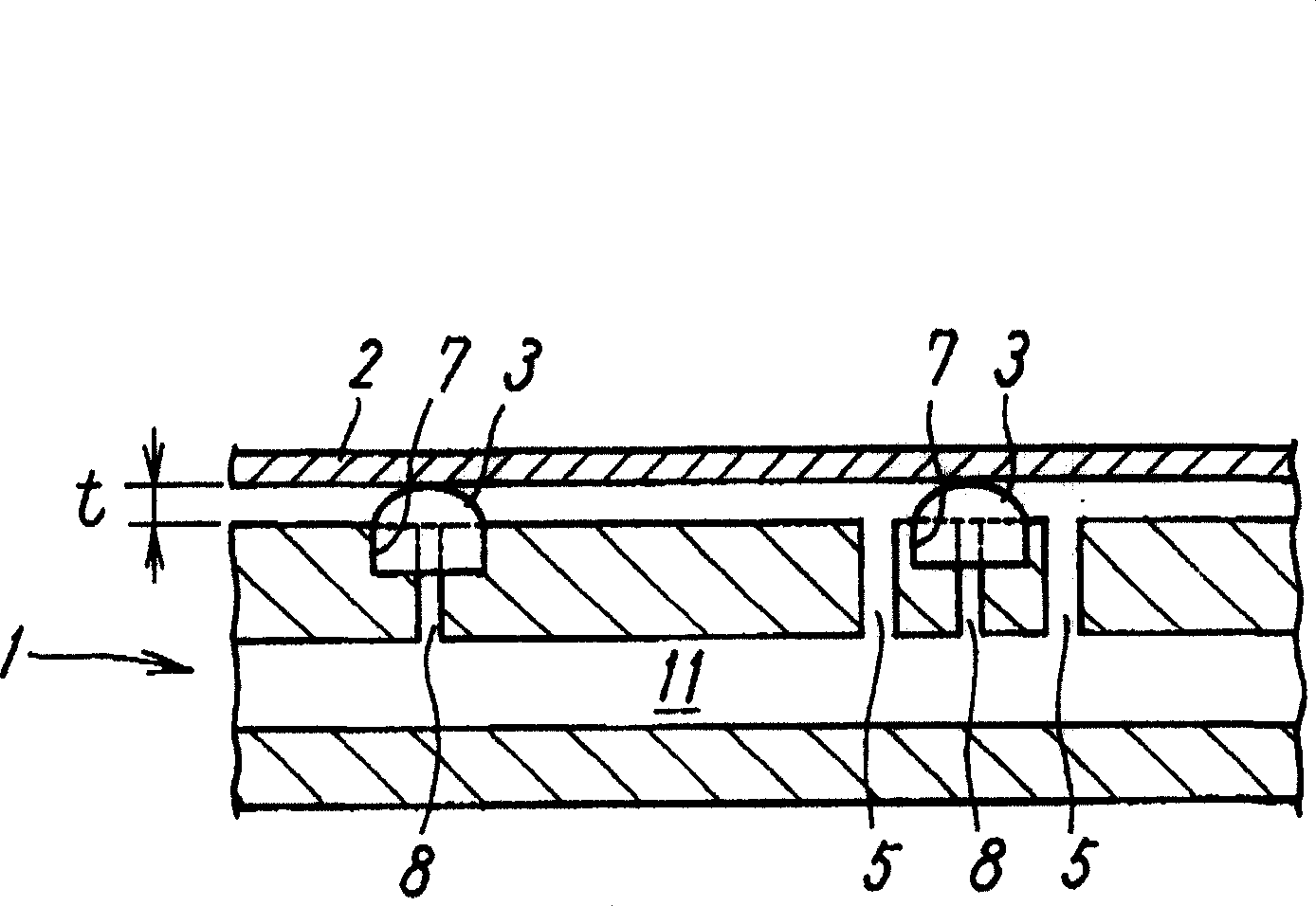

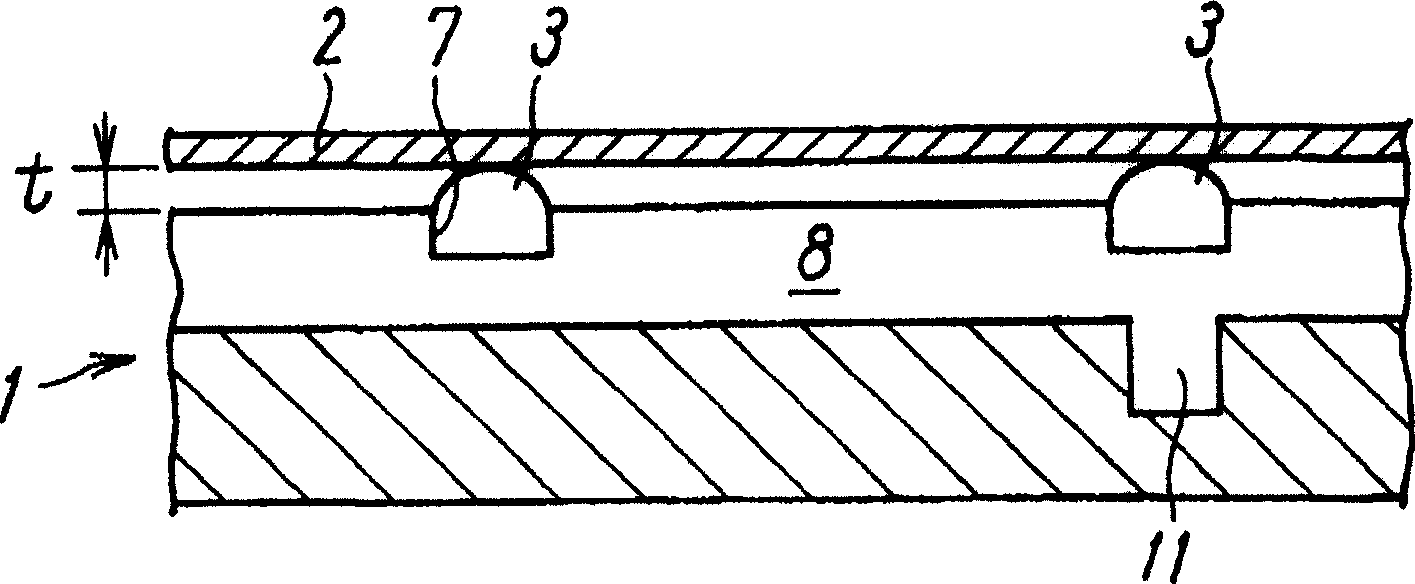

[0025] Embodiments of the temperature adjusting device of the present invention will be described in detail below with reference to the accompanying drawings.

[0026] Figure 1-Figure 3 It is a diagram schematically showing a first embodiment in which the present invention is applied to a temperature control device for temperature control of a silicon wafer. The heat transfer plate 1 in the temperature regulating device, such as figure 2 and image 3 As shown, a silicon chip 2 is placed on it for heating or cooling to a specified temperature, and it also has a temperature regulating part, which is inside a surface plate made of a good thermal conductor aluminum or copper-based material Side mounts incorporate Peltier elements, etc.

[0027] On the surface of the heat transfer plate 1, in order to prevent particles from adhering to the silicon wafer 2, a plurality of gap-forming members 3 made of ceramics having hemispherical tops are discretely provided. The gap forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com