Polymer colloid photon crystal membrane with photon band-gap position in middle infrared region and preparation method and usage thereof

A technology of colloidal photonic crystals and photonic bandgap, applied in the direction of fireproof coatings, etc., can solve the problem of high cost, and achieve the effect of low cost, simple equipment, and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Preparation of a polymer colloidal photonic crystal film with a photonic bandgap position in the mid-infrared region

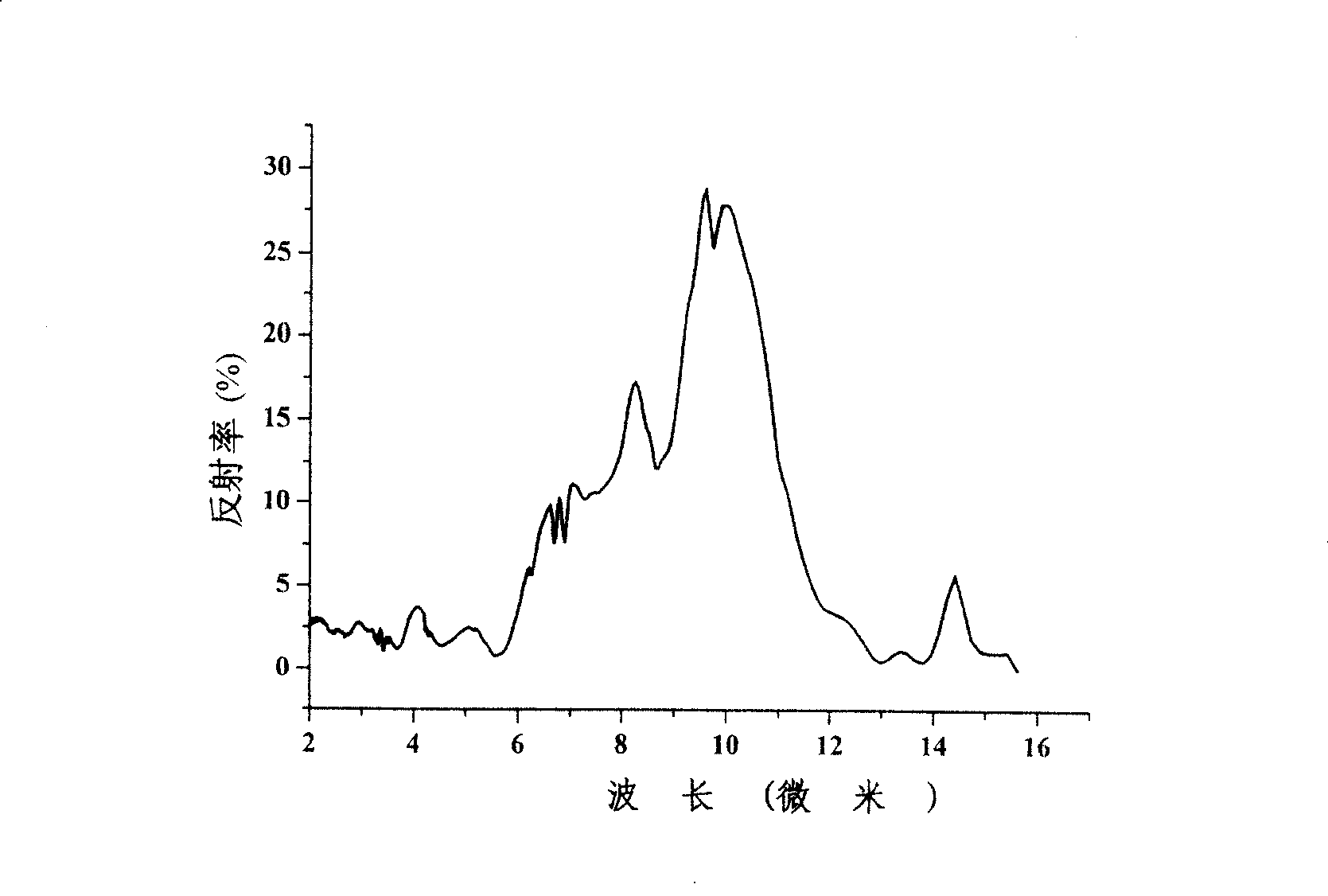

[0041] At room temperature, the poly(styrene-methacrylate-acrylic acid) terpolymer emulsion with a concentration of 5wt% and a monodisperse particle size of 3 μm is evenly covered on a clean glass, silicon wafer or stainless steel plate base. On the substrate, after the water in the dispersion liquid evaporates and dries up at normal temperature (15-30°C) and normal pressure, the monodisperse large-particle-diameter polymer latex particles are piled up on the substrate in a face-centered cubic manner, and form a periodic arrangement. Three-dimensional photonic crystal film. The photonic bandgap position of the prepared colloidal photonic crystal film involves 6-12 μm (such as figure 2 shown). SEM photos as figure 1 shown.

Embodiment 2

[0042] Example 2: Preparation of a polymer colloidal photonic crystal film with a photonic bandgap position in the mid-infrared region

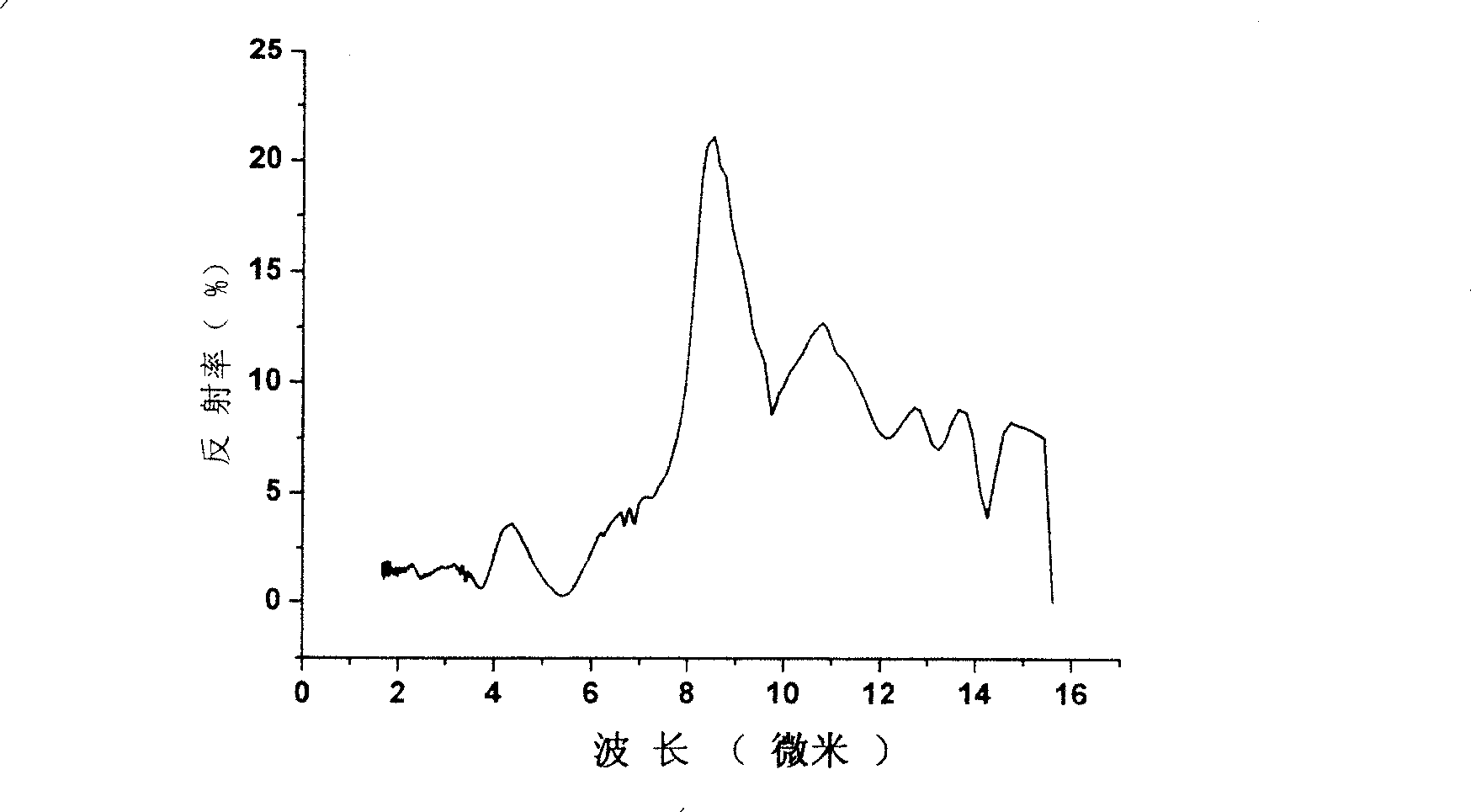

[0043] According to the method of Example 1, a poly(styrene-butyl acrylate-acrylic acid) terpolymer latex particle emulsion with a concentration of 30 wt% and a monodisperse particle size of 2.5 μm was assembled into a photonic crystal film. The photonic bandgap position of the prepared colloidal photonic crystal film involves 6-12 μm (such as image 3 shown).

Embodiment 3

[0044] Example 3: Preparation of a polymer colloidal photonic crystal film with a photonic bandgap position in the mid-infrared region

[0045] According to the method of Example 1, a poly(methylstyrene-butyl acrylate-acrylic acid) terpolymer latex particle emulsion with a concentration of 15 wt% and a monodisperse particle size of 2.8 μm was assembled into a photonic crystal film. The photonic bandgap position of the prepared colloidal photonic crystal film involves 8-12 μm (such as Figure 4 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com